TPO Roofing Systems

- Family Description

-

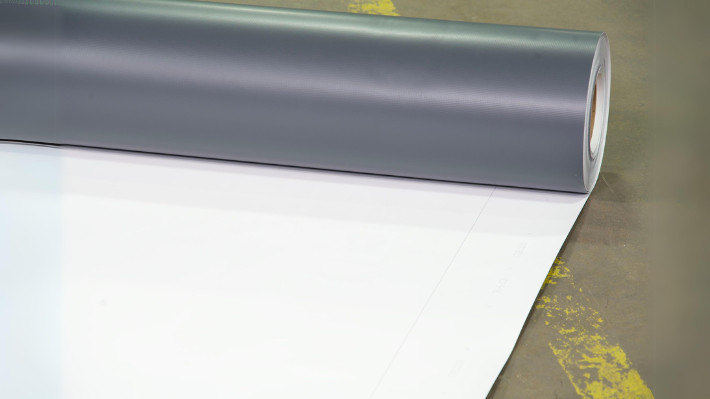

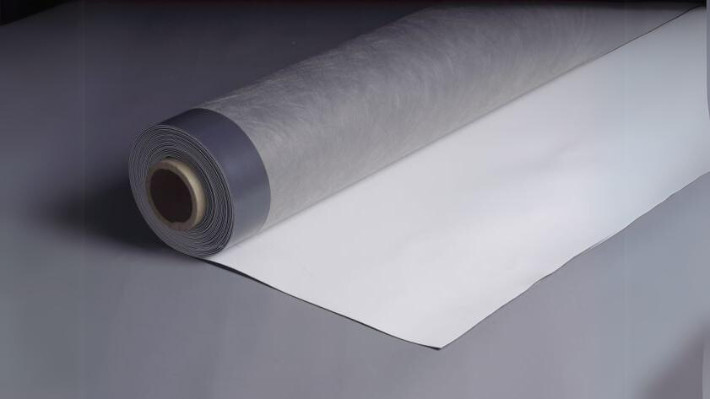

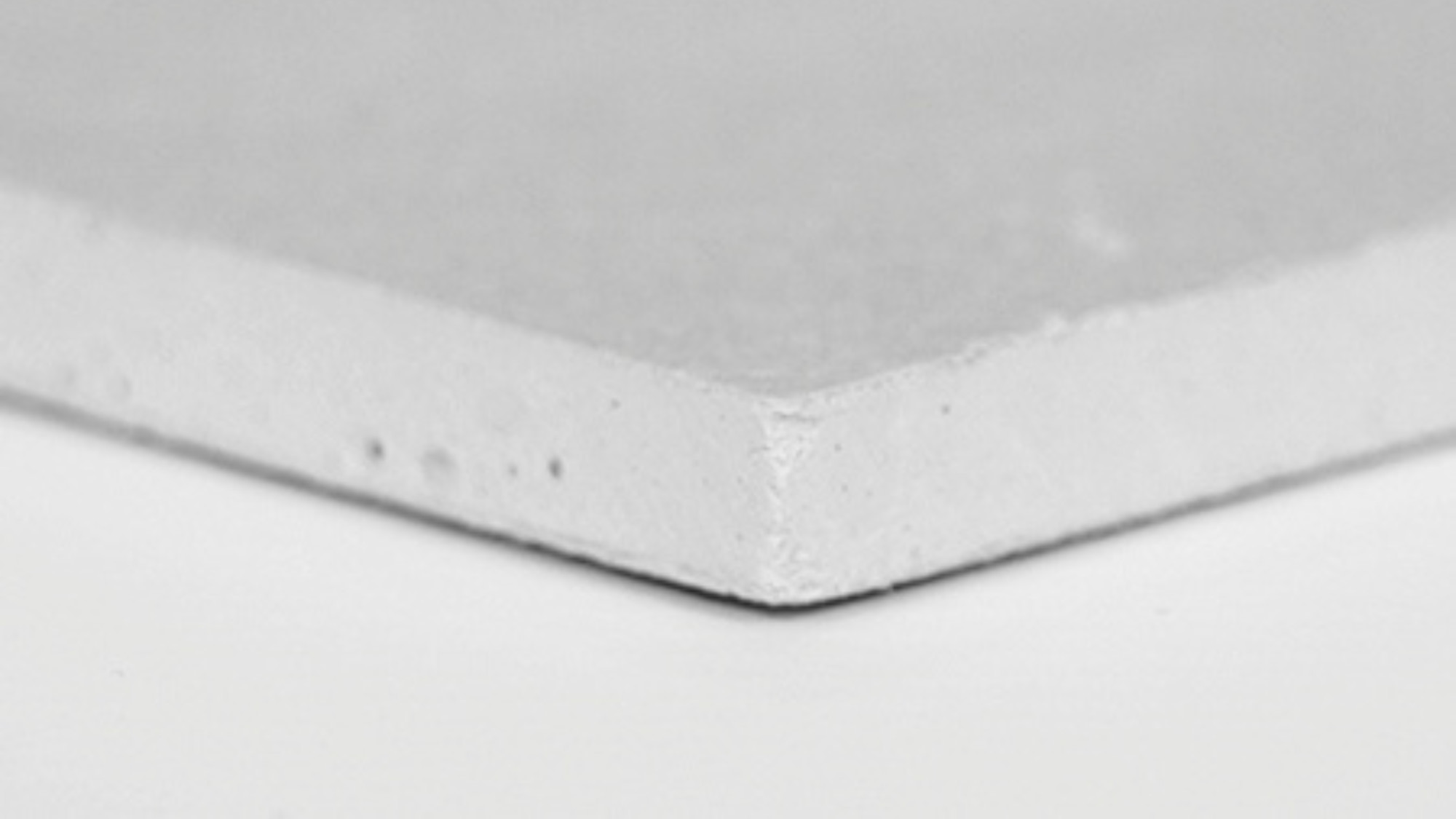

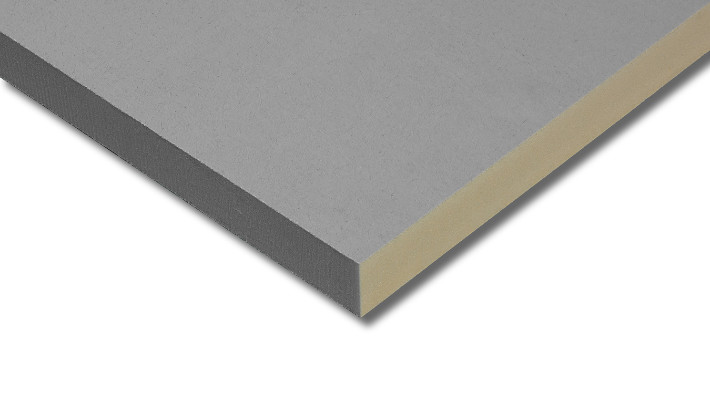

Our JM TPO roofing systems give you the option of a reliable, cost-effective roofing solution.

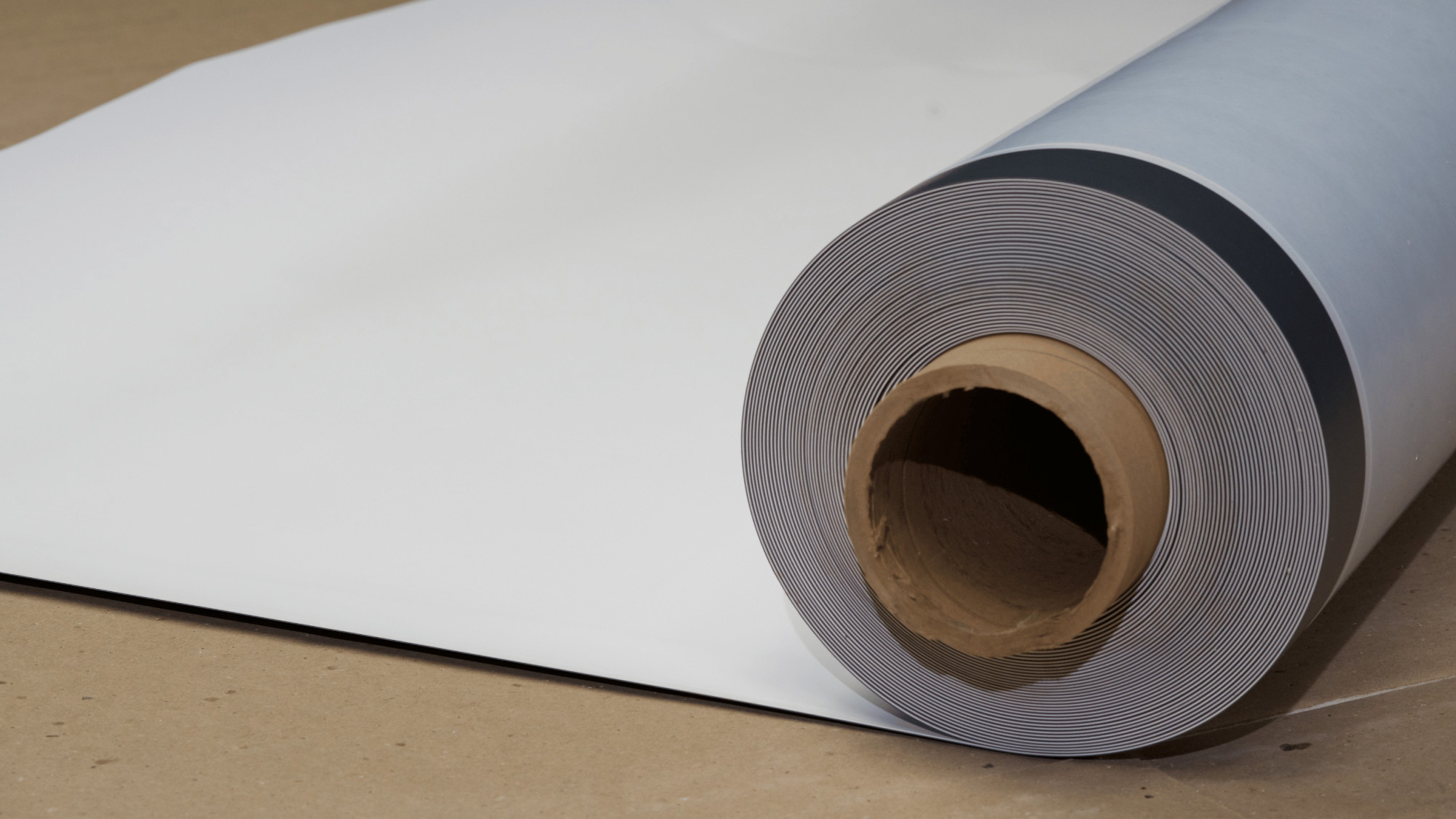

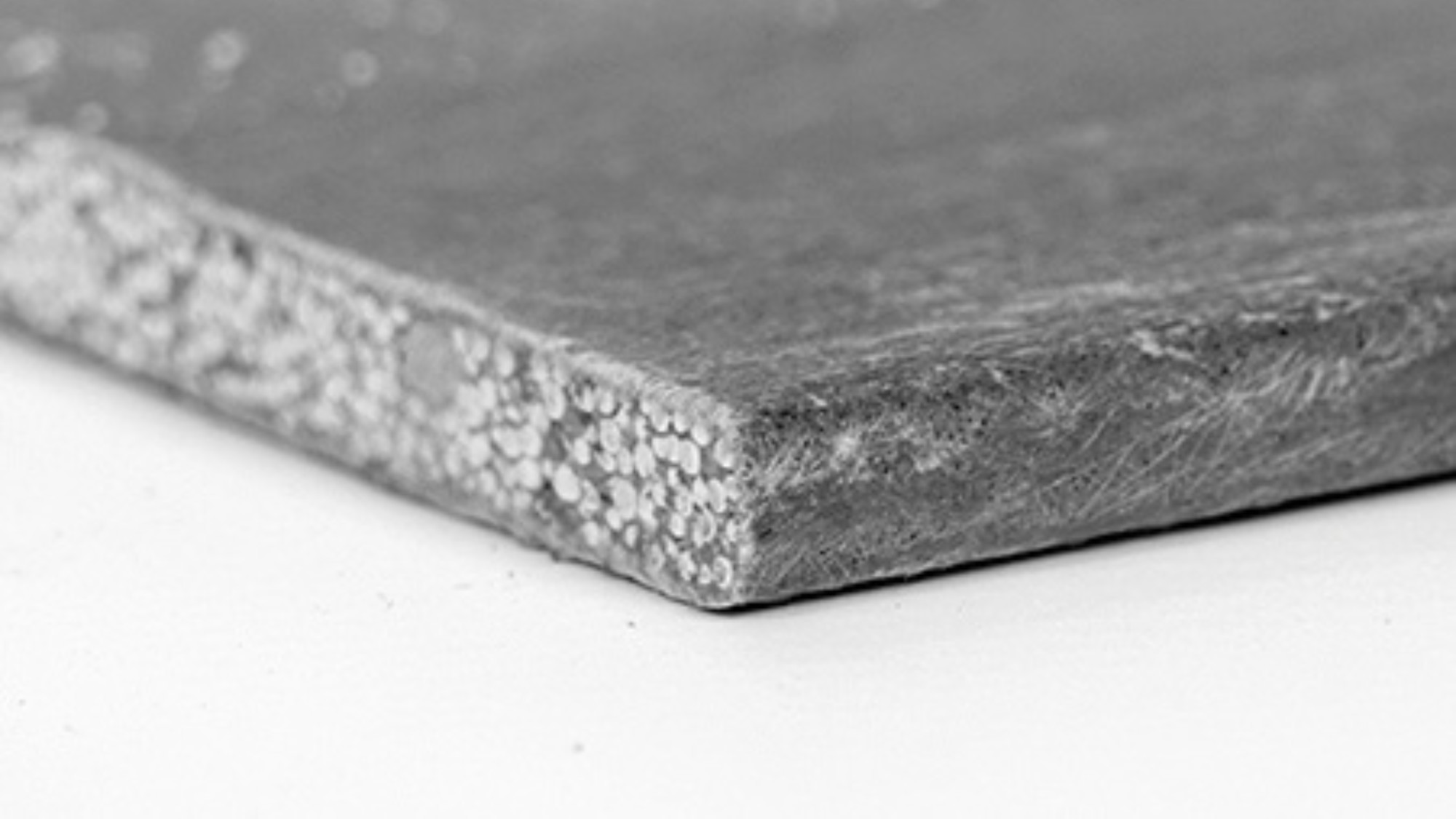

We reinforce our membranes with a polyester fabric and manufacture them using an ultraviolet-resistant thermoplastic polyolefin formulation.

We developed our TPO formulation to allow for extreme pliability, flexibility and weldability during the installation.

.png)