Roof Insulation and Cover Boards

- Family Description

-

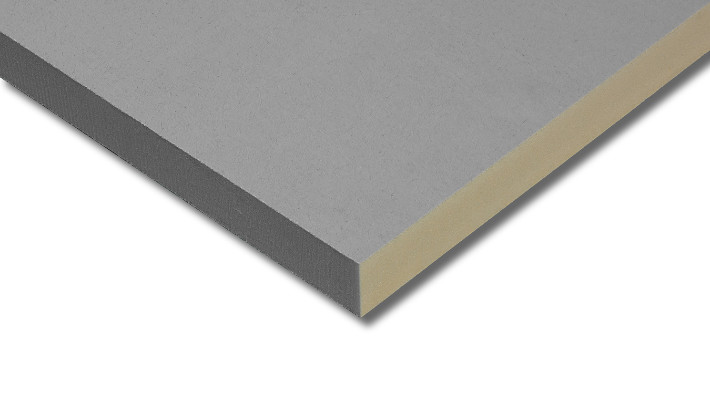

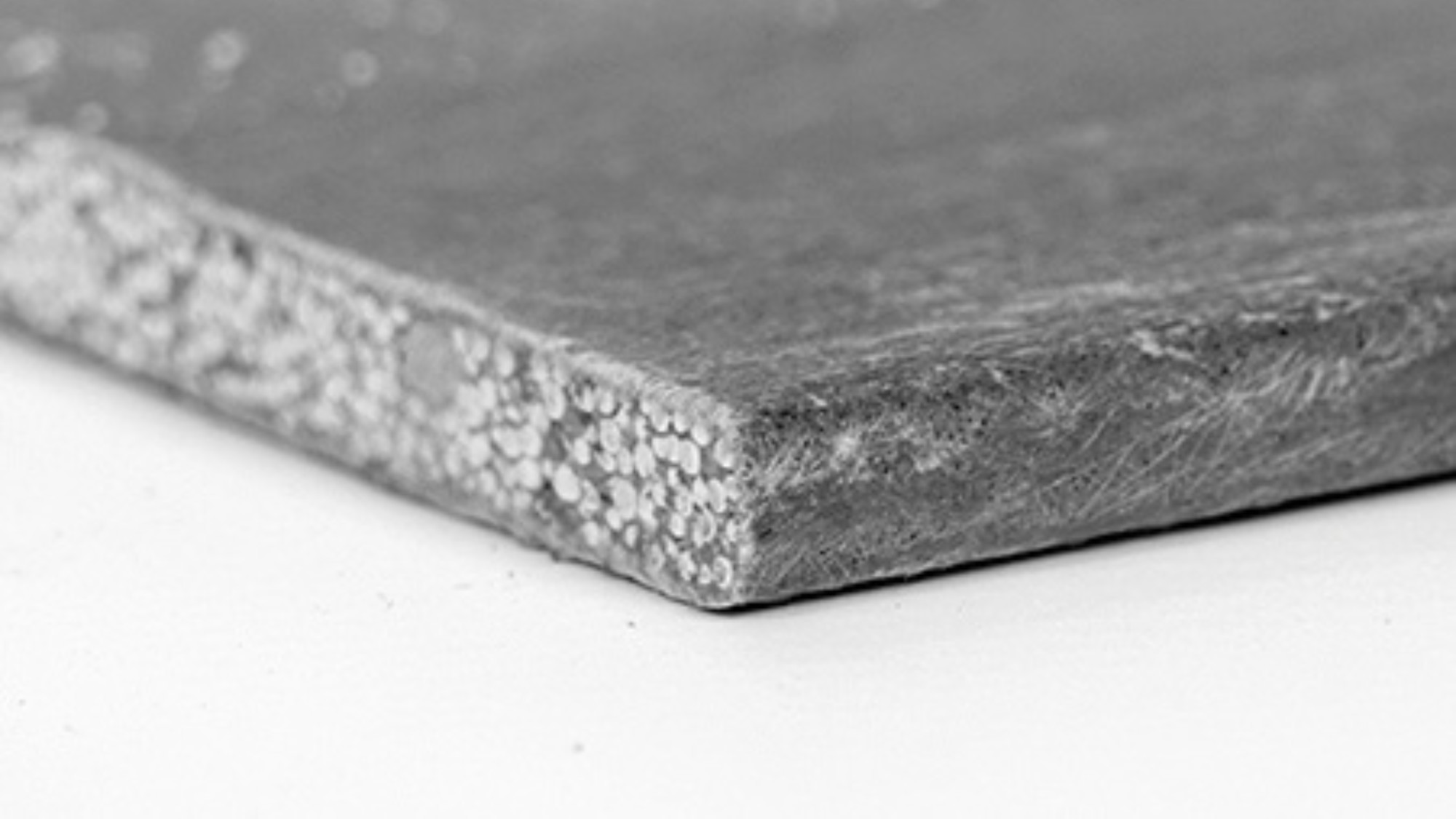

Our broad line of polyiso insulation products can address your R-value requirements. We are a PIMA member and are audited by their QualityMark program. We have a wide range of facers that cover all ASTM Type II designations, and we offer a full line of composite products.

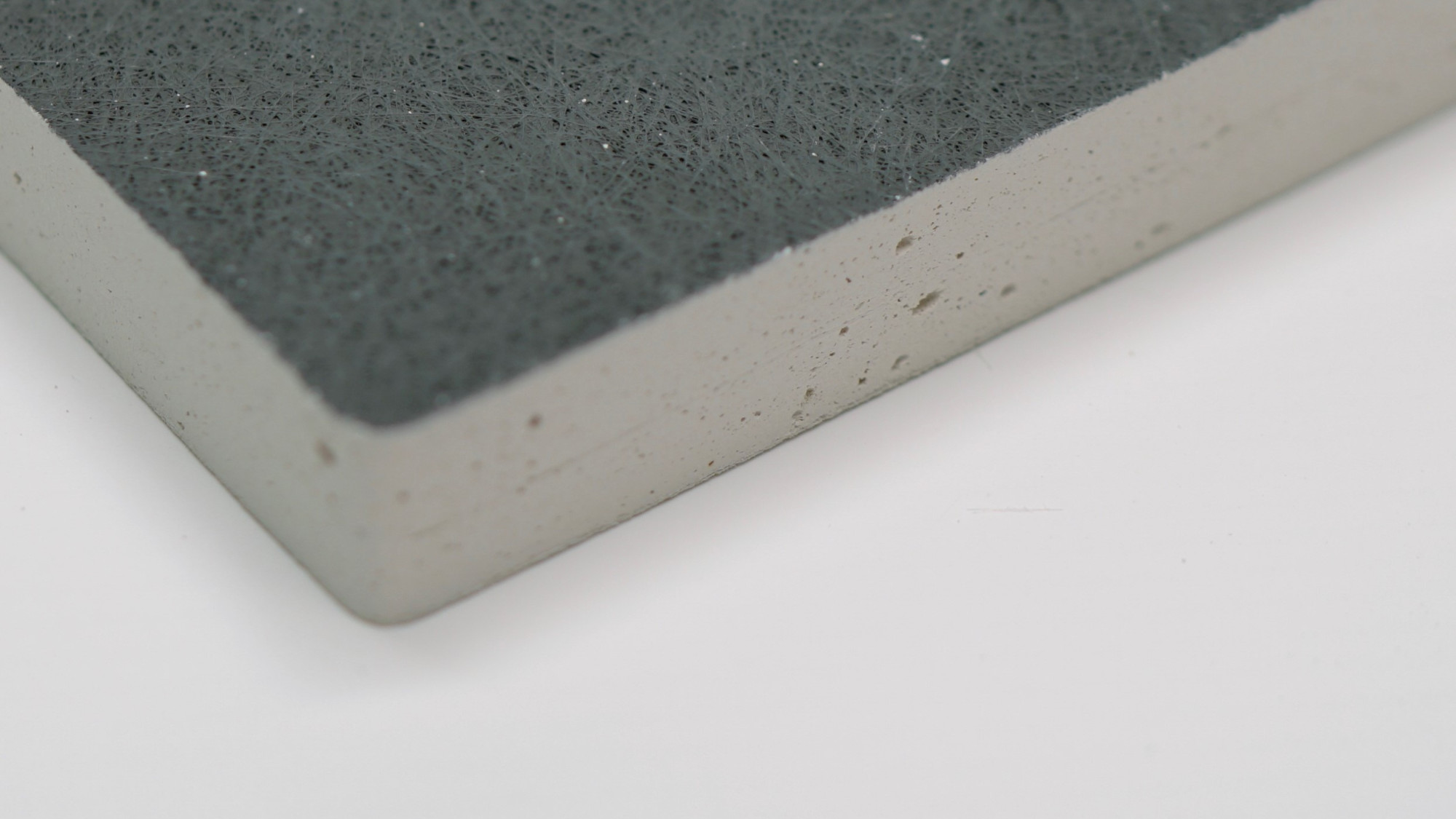

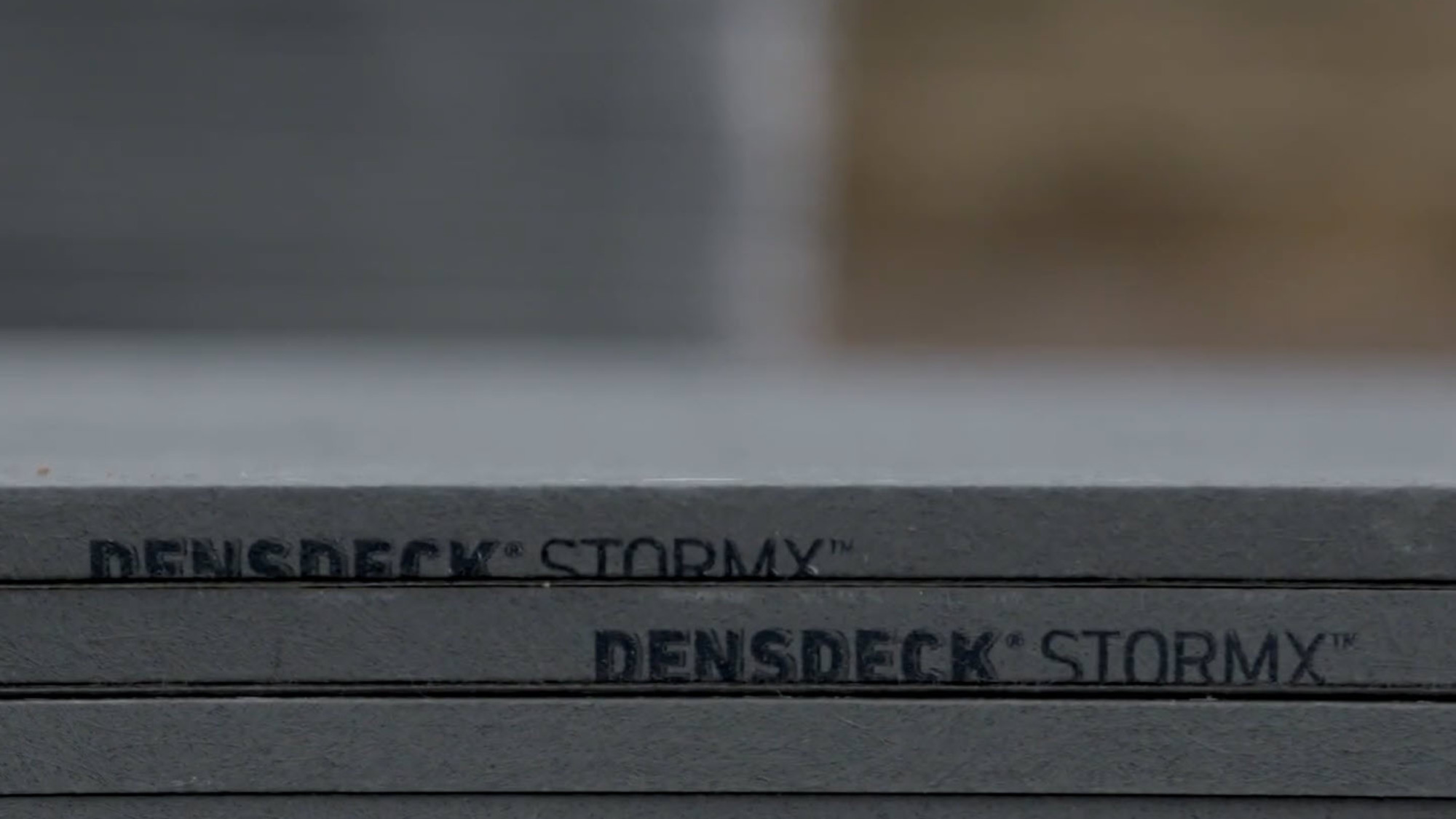

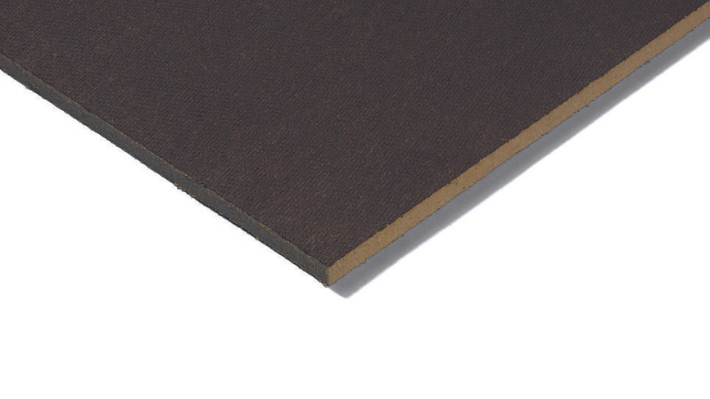

Adding a cover board enhances the long-term performance of a commercial roofing system. We offer high-density polyiso, low-density polyiso, cement, and gypsum cover boards. We've got you covered with solution for all situations you might encounter: a system for high-impact zones, fire-retardant solutions that meet UL Class A requirements, products that do not support mold growth and more.