Specialty Roofing Products

- Family Description

-

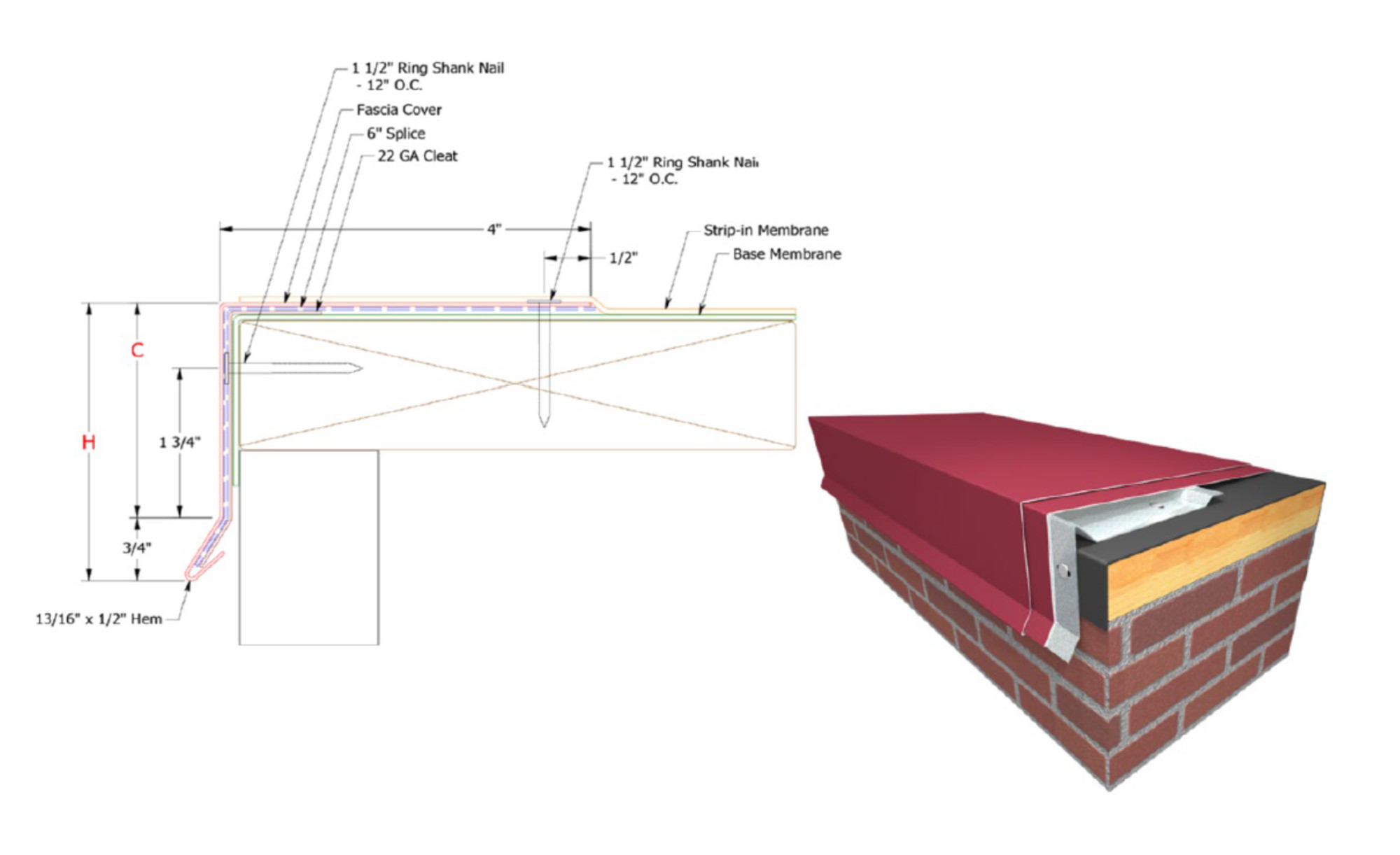

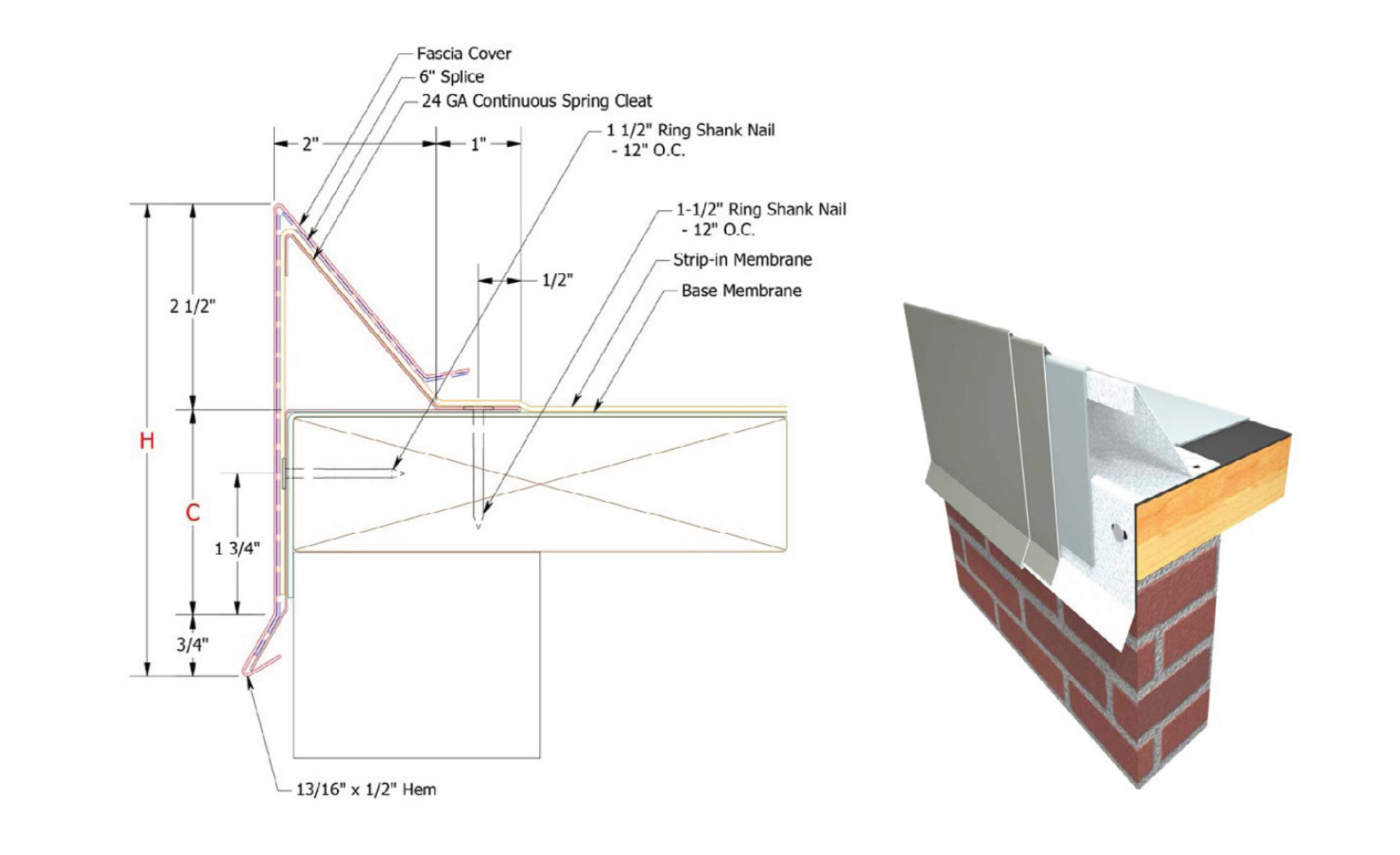

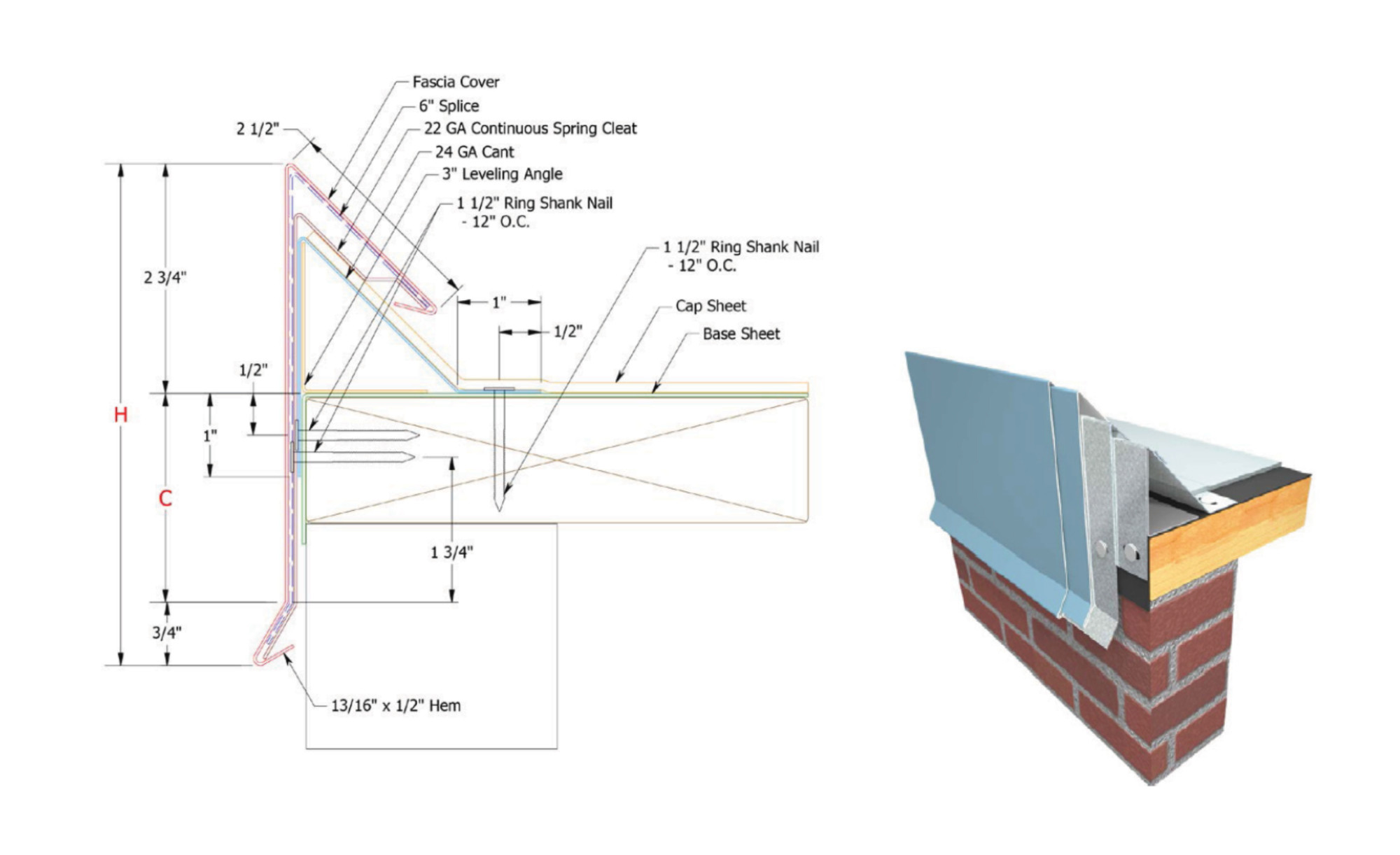

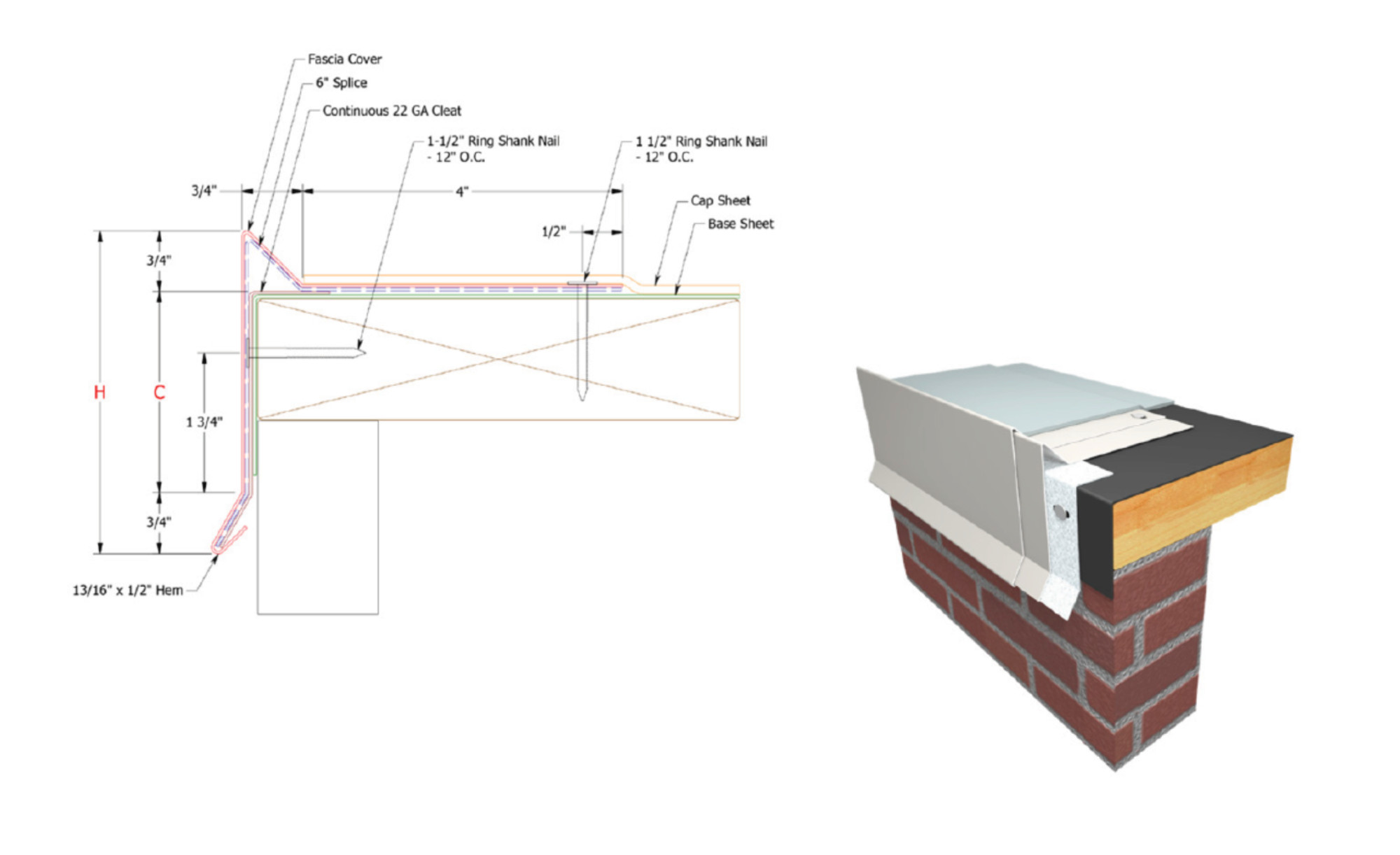

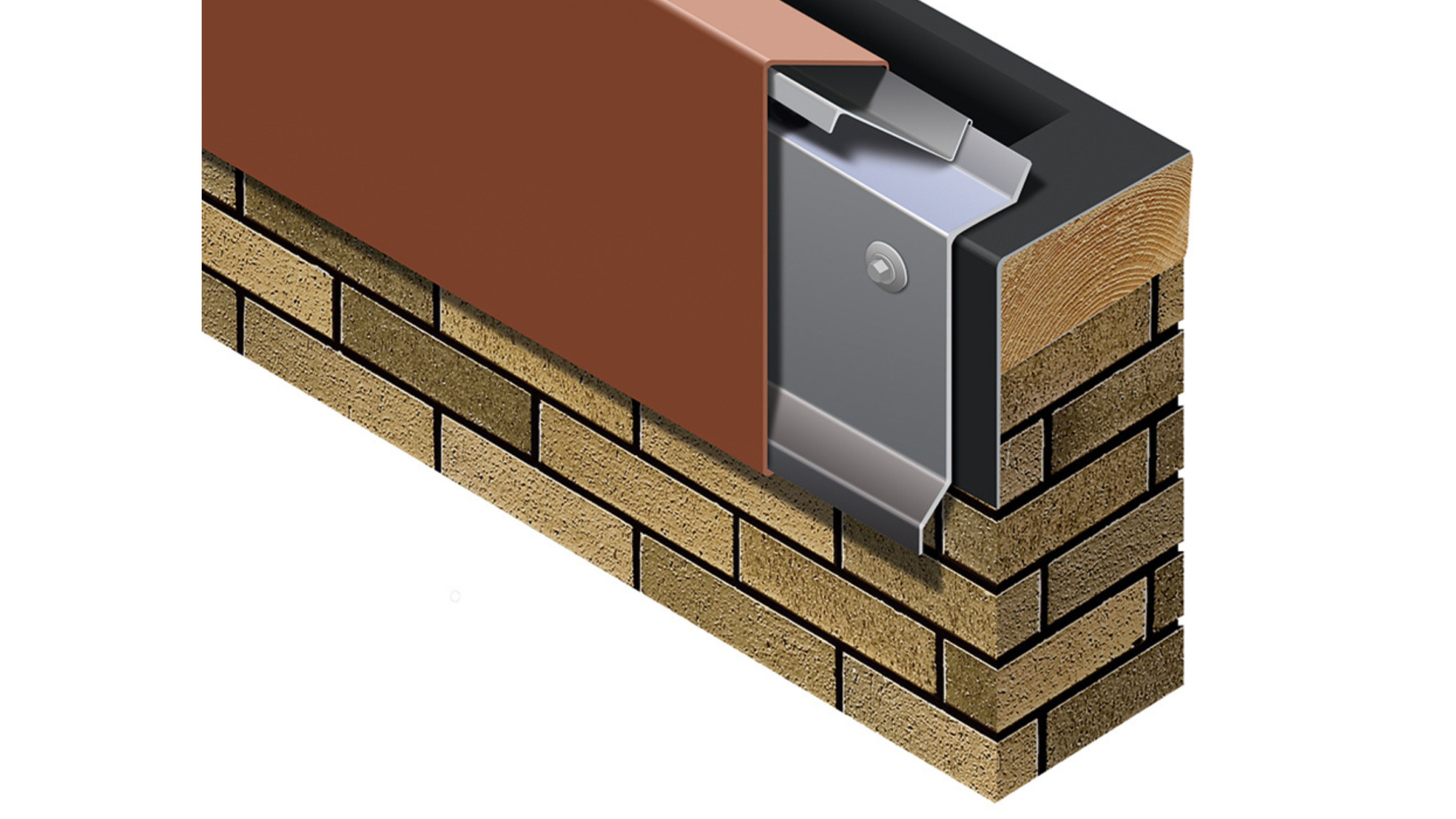

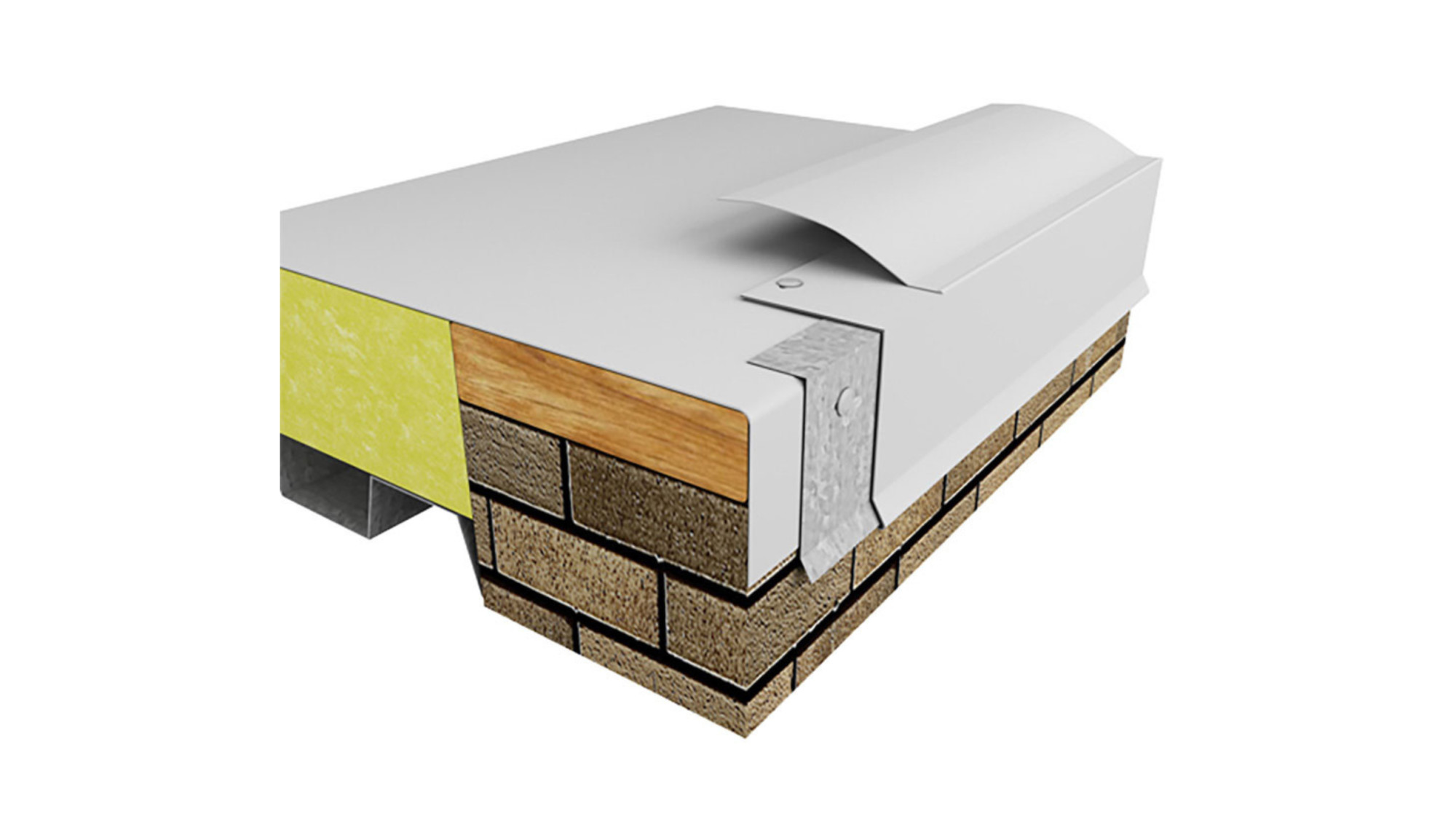

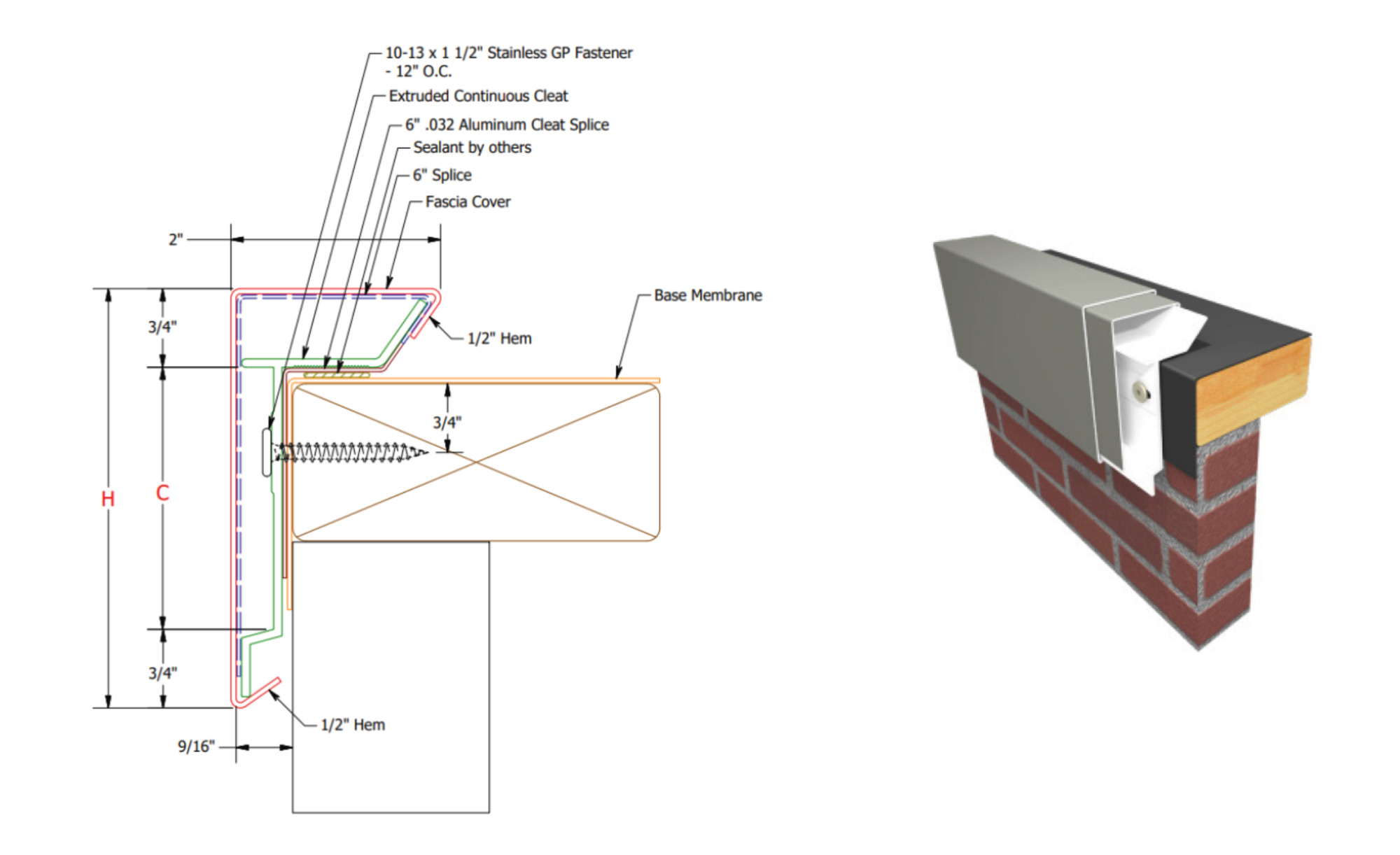

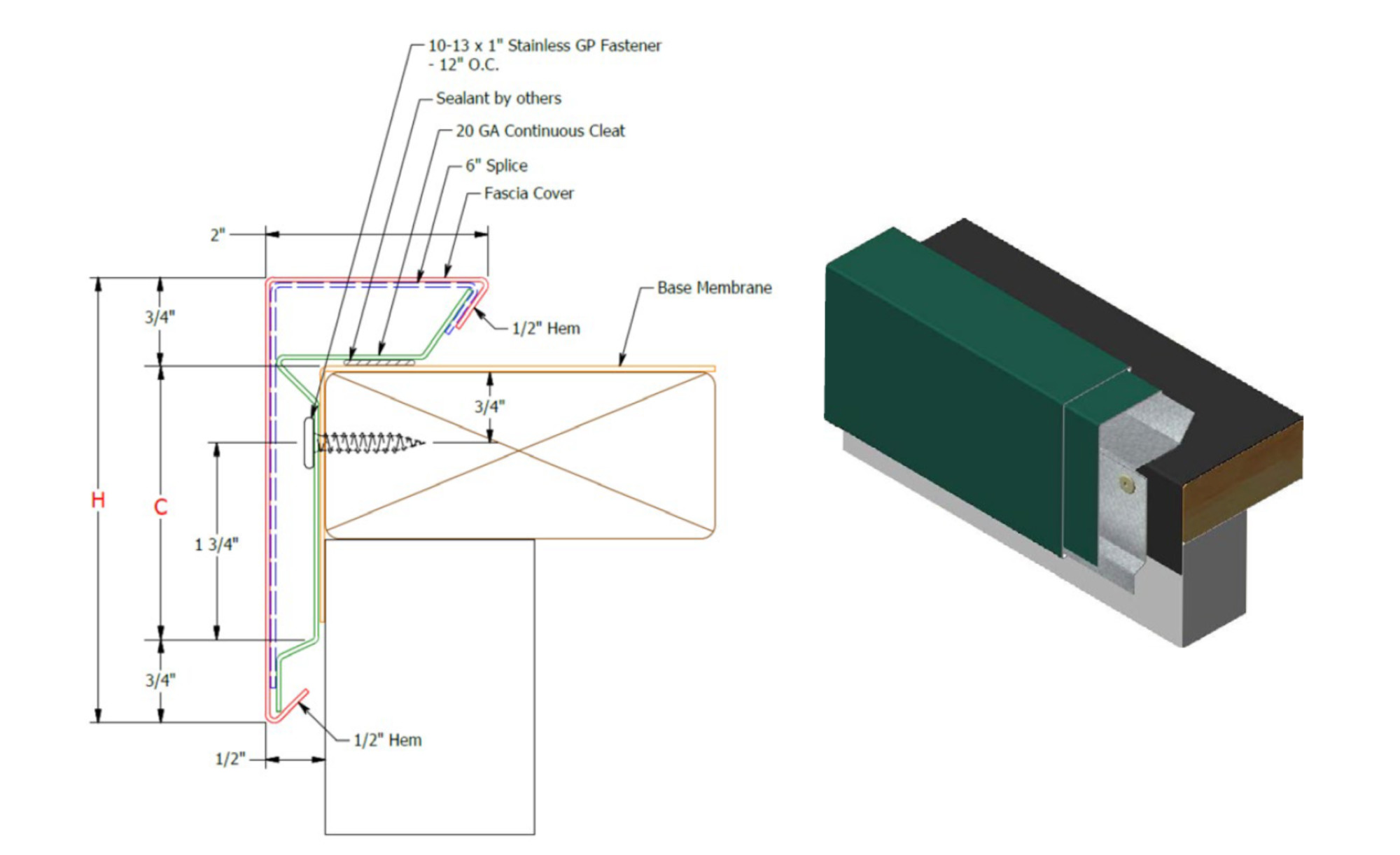

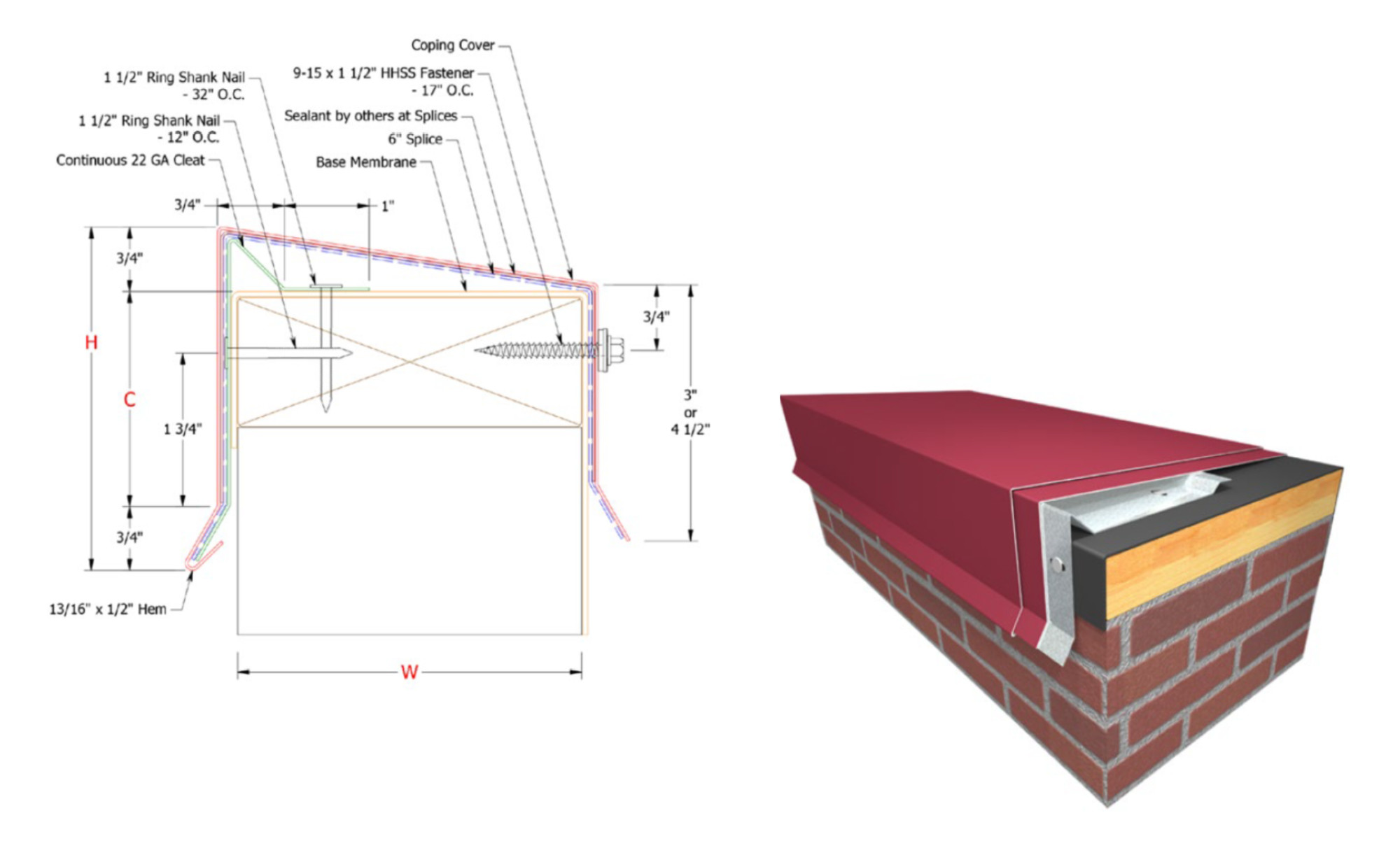

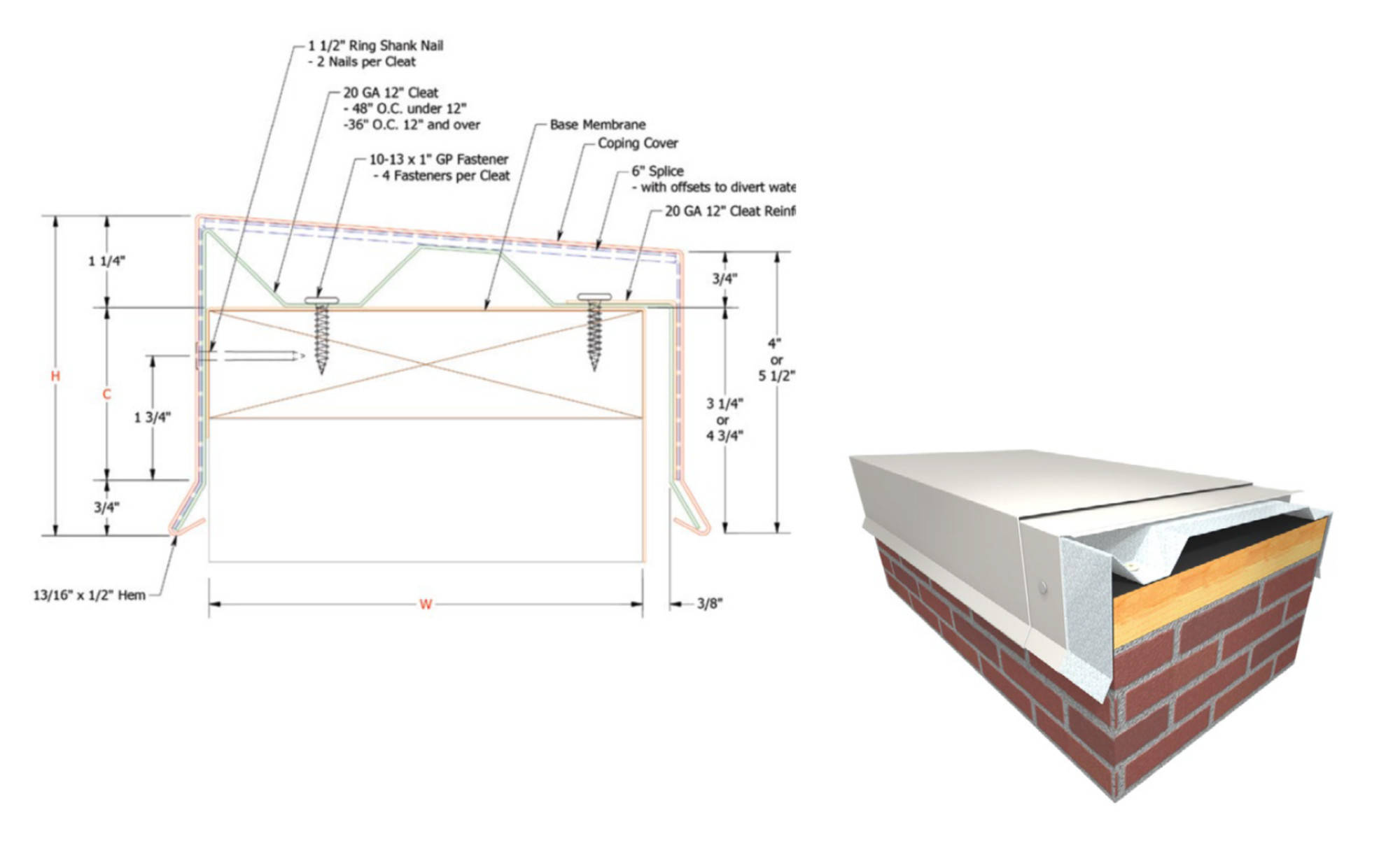

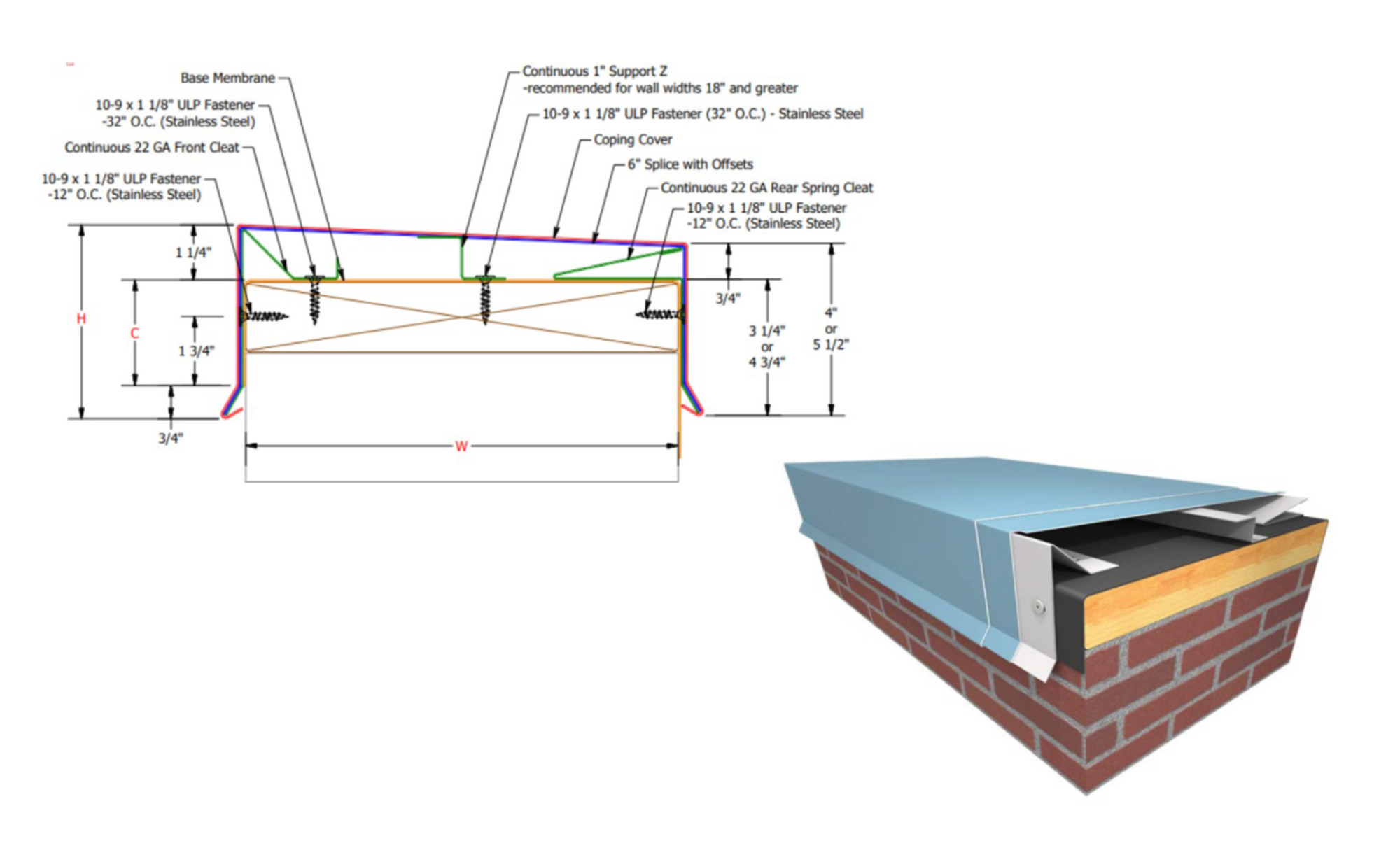

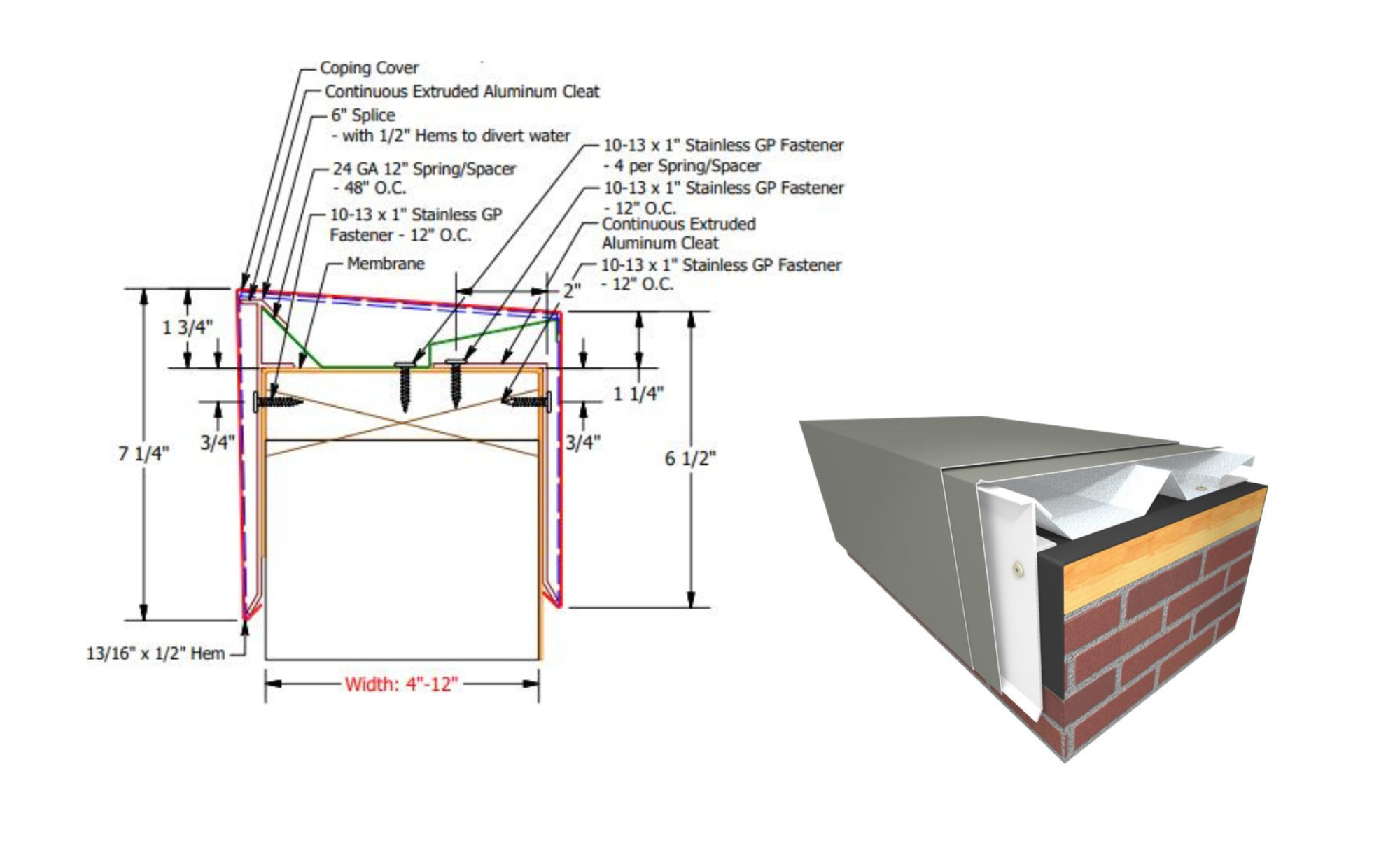

At Johns Manville, we provide our customers with the most complete set of products found in the commercial roofing industry. We offer a full line of specialty products to support SBS and APP modified bitumen and EPDM, PVC and TPO single ply membrane systems. This selection includes expansion joint covers, edge metal systems, retrofit drains and tie-in flashing systems. Architectural drawings, along with CSI format short- and long-form specifications and details, are also available.

We help our customers be successful by providing access to specialty roofing products and resources to complete the full JM roofing system. By using a single-source roofing systems provider, our customers have the reassurance that they can receive a total roofing systems guarantee.