Liquid Applied Family

- Family Description

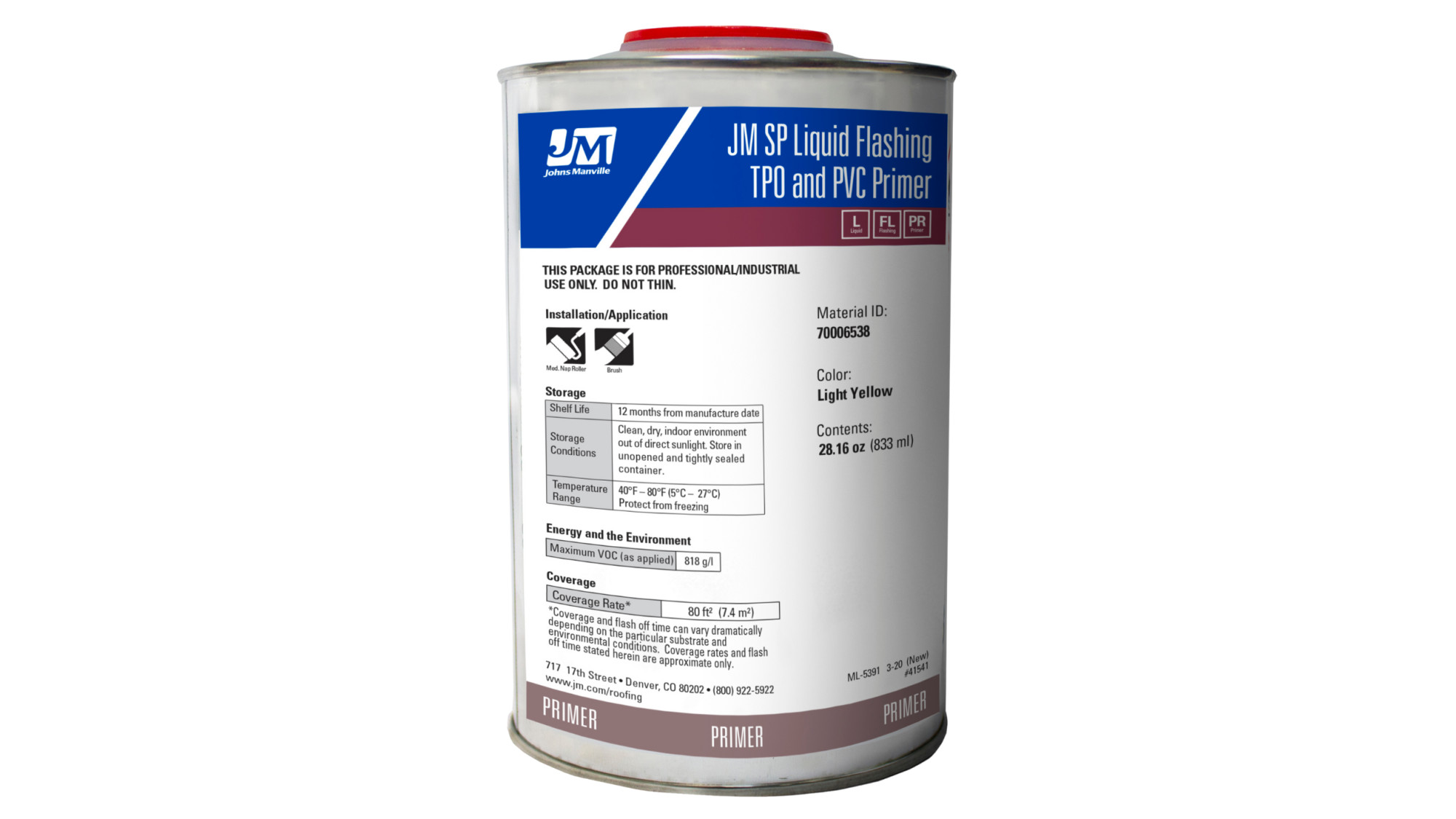

- Our liquid-applied systems provide seamless waterproof membranes that are easily applied and conform to any penetration shape. This system is ideal when faced with a confined urban space, numerous roof penetrations or is restricted on the use of hot asphalt or heat welding.