Optimizing Acoustic Performance in Pipe Systems

Proper acoustic design can serve multiple purposes. It can help with noise control and it can also improve the ability of building occupants to enjoy the space. Johns Manville is committed to providing solutions for acoustic concerns with a broad range of products including Micro-Lok® HP pipe insulation and Zeston PVC® Jacketing.

Acoustic Solutions on the Market

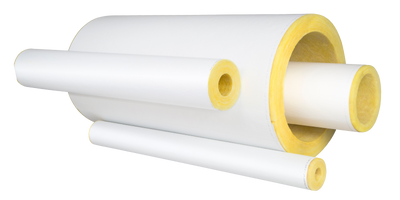

Micro-Lok® HP Pipe Insulation

Pre-formed fiberglass pipe insulation with an ASJ jacket. In-line manufacturing process (service temp: 850°F).

Download Data Sheet

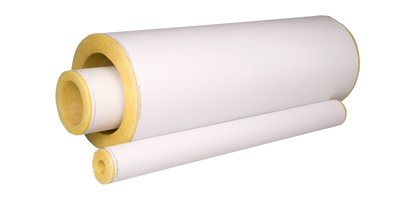

Micro-Lok® HP Ultra Pipe Insulation

Pre-formed fiberglass pipe insulation with a polycoated jacket. In-line manufacturing process (service temp: 850°F).

Download Data Sheet

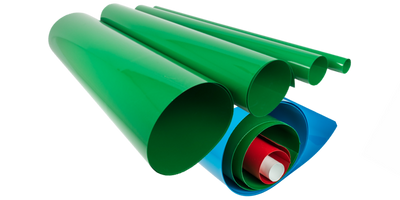

Zeston® PVC Jacketing

Standard and heavy gauge PVC jacketing designed to provide an inherent vapor retarder and protection to insulated pipes.

Download Data Sheet

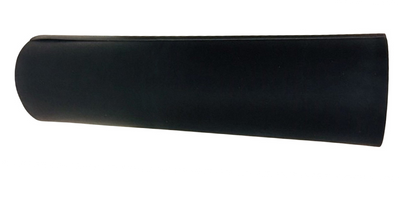

Mass Loaded Vinyl

JM's Mass Loaded Vinyl noise barrier is a flexible, non-reinforced mass loaded vinyl that resists the passage of sound waves and reduces the transmission of airborne noise.

Download Data Sheet

Download the White Paper

Design Considerations for the Acoustics of Piping Systems in Multi-Tenant Buildings

Offices and multi-tenant residential buildings, such as high-rises, condos and duplexes present distinct acoustical challenges. ASTM International has developed two standard test methods that can be helpful for engineers specifying pipe systems for multi-tenant buildings.

Design Considerations

Keep tenants happy by designing pipe systems with acoustics in mind. Here are some things to consider when designing the piping systems for multi-unit office and residential buildings:

1. Isolate plumbing pipes. Isolate the plumbing system pipes and drains from your walls or ceiling assemblies. Ideally, where plumbing is installed in double-stud assemblies, it should be installed only on the stud row of the unit that it serves.

2. Specify the right products. Using a heavy pipe for wastewater, such as cast iron, will help minimize noise. Ideally, the pipe would be enclosed in the wall assembly, located in a space where this noise would be more acceptable, such as a hallway. When you have a pipe in a wall assembly, specify gypsum panels around the pipe. Gypsum board panels can help reduce background noise. Where PVC is used, fibrous pipe lagging with a jacket can reduce breakout flow noise. The heavier the jacket, the greater the performance will generally be. Using mass-loaded vinyl would be best, and a PVC jacket would provide better performance than just an all-service jacket.

3. Ensure that insulation is correctly installed. Design teams must work together with installers to make sure that insulation around the piping systems is installed correctly. When insulation is not installed properly, acoustic performance can be much lower than what was expected.

4. Insulate walls properly. Insulation isn’t just about thermal performance, it’s also about acoustical control. As more designs incorporate single-stud assembles, walls are becoming thinner, which results in more noise traveling among units. So it’s a good idea to fill the cavity in a wall assembly with a fibrous insulation product. An empty wall cavity can turn into a drum chamber, transmitting and amplifying noise. Most wall assemblies without fibrous insulation will not meet International Building Code minimum performance requirements and may result in noise complaints.

5. Do it right the first time. The cost of retrofitting an existing piping system to reduce unwanted noise would be extremely high and involve either replacing existing pipes with cast iron or installing mass-loaded vinyl jacketing over the existing pipes. Installing jacketing will be less invasive than a complete pipe replacement. However, both of these approaches would involve opening walls and having to redo finishes. Further, it is extremely unlikely that any retrofit would be able to incorporate all of the elements that can be included in the original construction when taking a proactive approach to the project.

Insulation Intel® Project Profile

RBC Gateway High-Rise Apartments

Installing top-of-the-line soundproofing on mechanical systems for high-end residences.

Product: Micro-Lok® HP, Zeston® PVC, Mass Loaded Vinyl

Installer: Insulation Midwest Inc., St. Paul, Minnesota

Insulation Midwest Inc. recently won a bid to work on RBC Gateway, a mixed-useconstruction project in downtown Minneapolis. The city’s downtown area is currentlybooming. Downtown Minneapolis added 1,500 new apartment units in 2021 and topped$1 billion in new construction permits for the tenth straight year. When the project isfinished, RBC Gateway will be one of the 10 tallest buildings in downtownMinneapolis. It includes commercial space, office space and single-family residences.

.png)