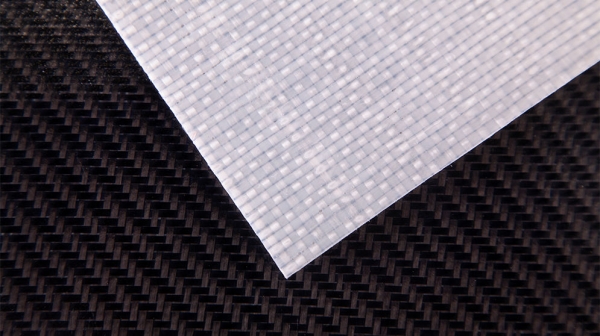

In the dynamic realm of electric vehicles (EVs), the pursuit of lighter and more efficient solutions has taken center stage. That is something that makes our Advanced Composites team’s heart beat faster and they unveiled a groundbreaking alternative for electric vehicle battery enclosures with the Neomera® PA-6 thermoplastic organosheet.

Lighter, Greener, and Fire-Tested

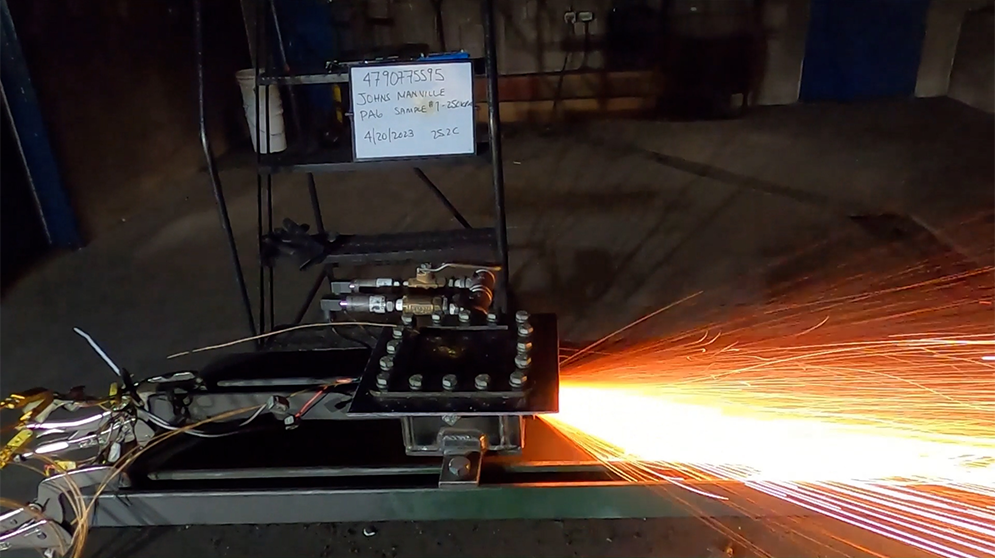

As the demand for environmentally friendly innovations grows, Neomera® organosheet has successfully passed stringent UL 2596 and pyrotechnic fire testing at a mere 3 mm thickness. This achievement introduces a lighter and eco-friendly alternative to the traditional materials commonly used in EV battery enclosures.

A key differentiator is that the organosheet, with a glass content of only 65 wt% and devoid of flame-retardant chemistries, sets itself apart from most other glass fiber reinforced composites. This breakthrough not only meets fire resistance standards but does so with a thin profile, potentially reshaping the future architecture of EV battery enclosures.

A Game-Changing Solution

This innovative product opens new possibilities, as demonstrated by a collaborative effort.

“Our partner Agesia Structural Composite Technology, developed a trailblazing 17 mm sandwich panel using 2 mm Neomera organosheets as outside layers and a 3A Composites PET foam middle layer. This incredible sandwich panel combines both underbody protection and battery bottom in a single thin profile that has also passed the pyrotechnic test”, says Dany de Kock, Market Development Manager at Johns Manville.

“This thin profile could translate into more than 1 cm of additional underbody-space, allowing for the potential to increase battery capacity or create higher clearance between the vehicle’s underside and the ground, allowing for enhanced design flexibility.”

The Neomera® Advantage

The PA-6 thermoplastic organosheet stands out as a lightweight, recyclable, and cost-effective solution with a lower density compared to conventional materials. Comprising only PA-6 and glass fibers, it is fully recyclable, with significantly lower smoke and toxicity levels than materials containing extra additives.

Its ability to pass all fire tests without the need for fire-retardant additives, coupled with its thinner profile, positions Neomera® as an excellent choice for manufacturers aiming to optimize the performance, safety, sustainability, and design of electric vehicles in the evolving automotive landscape.

In the race towards a greener and more efficient automotive future, the material emerges as a catalyst for change, promising a safer, lighter, and more sustainable path for the electric vehicle industry.

-

Engineered Products

-

Engineered Products

-

Engineered Products

-

Engineered Products

-

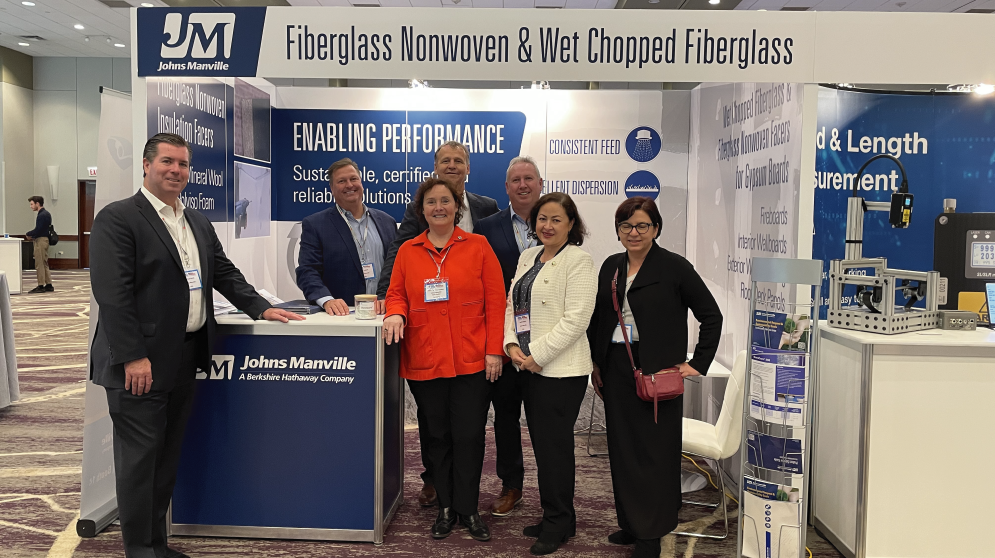

Engineered ProductsIndustry Insights, Sustainable Innovations, and Market Adaptability: A Comprehensive Overview from the Global Gypsum & Insulation Conference 2023

-

CommunityInternational Glass Artist Blends Illusion and Reality Using Johns Manville Materials

-

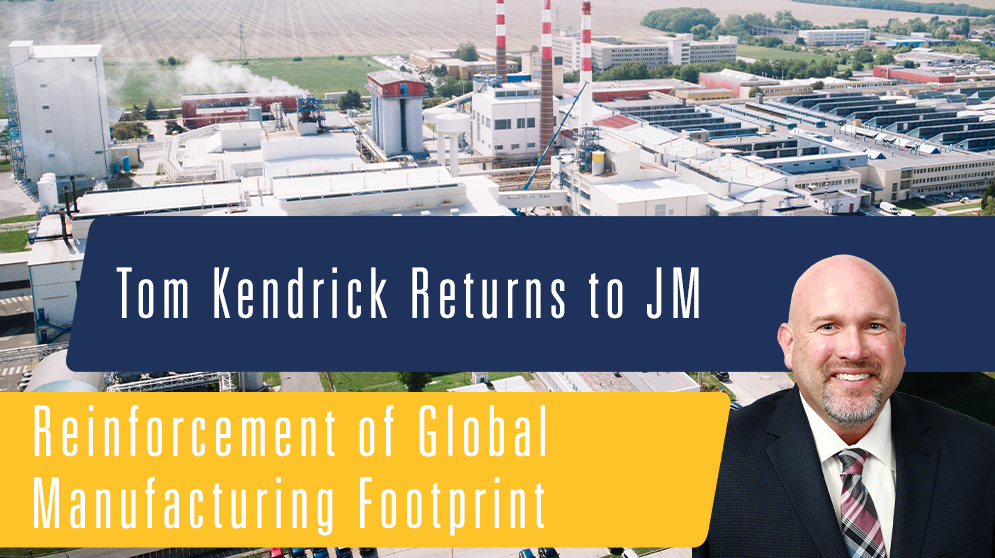

Engineered ProductsJM Reinforces Global Manufacturing Footprint as Tom Kendrick Returns as Global Fiberglass Commercial Director

-

Engineered Products