With a background in engineering, it is only natural that Philippe Bekaert sees sustainability as a train – one that has been gaining momentum and picking up speed as it heads down the tracks. During Philippe’s 20-year career at JM, he was early to board the sustainability train and has seen how it’s been evolving as a part of the business. Residing in Europe, he observed how sustainability has become a growing factor in the marketplace and a global issue that offers both challenges and opportunities. Today as the Global Portfolio Leader for Engineered Products – Nonwovens, Philippe offers unique insights informed by a logic-driven passion for sustainability supported by real-world experience.

Can you describe your journey at JM? What are your roles and responsibilities?

My journey at JM started 20 years ago with experience in advanced materials and composites. I am an engineer with a business administration background. When JM was looking for growth in the engineered products division, I joined JM started on the commercial side, then transitioned into strategic marketing. My current role is the Global Portfolio Leader for nonwovens within Engineered Products. I work on examining our product profitability mix both currently and in the future. We consider drivers in the marketplace, which means we must anticipate where the market will evolve. We interact a lot with our stakeholders both internally across the commercial team and in innovation, finance, operations, quality, and senior leadership team and externally with customers and industry associations. There is a lot of collaboration happening across the globe.

For those unfamiliar with nonwovens, what are they, and what are their applications?

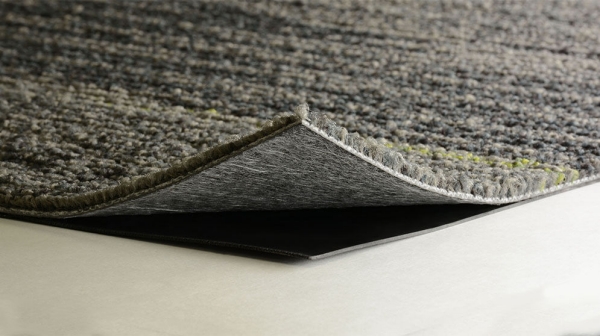

First, nonwovens are innovative, high-tech, engineered fabrics made from fibers. They are not woven like textiles used for garments, and the technology used to produce them is different from the textile fabric-making process. JM manufactures Evalith® nonwovens made of polyester spunbond as well as glass fibers. These materials are used in multiple applications, predominantly in the building industry, but not only. In the building market, they are used in the roof, exterior, insulation, and HVAC, as well as in the interior, in products like flooring, carpet, ceiling panels, gypsum boards, etc. Other applications include specific products that go into windmill blades in automotive and recreational vehicles, to mention just a few applications. Evalith® nonwovens are typically used as reinforcement and facers to improve the durability of our customers’ applications.

During your 20 years at JM, how have you seen the importance of sustainability evolve?

Sustainability has certainly evolved over the past 20 years. There has always been a demand for recyclability in Europe. Right now, there is a market-wide demand for it. Various initiatives on the sustainability front through (trade) associations and at the company level have emerged. I’ve seen companies at the forefront of sustainability engage us; I would say, starting in the early 2000s. They have continued to encourage us to innovate. My exposure to JM’s sustainability journey started in 2009. I remember during our first JM Academy forum, senior leaders, customers, as well as our CEO came together to discuss what the future would look like and what JM could do. One workshop was around sustainability. Back then, the word sustainability wasn’t used as much. While the wording has changed, the trends we discussed back then, like energy, are a significant topic now. We discussed how to move forward with lower CO2 products in the marketplace that save energy. I was happy to be there in that early phase.

You can see progress through our sustainability reports published over the years. And right now, there's also marketplace acceleration regarding demand. So, I think you could compare sustainability with a train. The train is moving. As a company, there are no options to say, “Well, I'm going to wait a little bit to board the train.” At JM, we have a choice, and we are already on the train. We are continuing to accelerate.

Where does your passion and commitment to sustainability come from?

The passion comes from observing where the market is going, then understanding what can be done. I'm trying to continue to learn about how different needs are related to sustainability. In the ‘90s, I was part of a recycling consortium. Some initiatives were successful, some less– and there was always a reason for that. There’s a pull from the marketplace where some end consumers look for sustainable products, but not everybody. The end customer must be willing to pay for the technology you develop, for instance, to improve your recycled content. So, we must be aware that this is a journey that is a little bit more complex than, say, green or not green. It’s more on the customer and legislation base, the market's requirements, and how new offerings are being introduced.

What sustainability achievements at JM have you been most proud of?

We're working on different avenues related to process innovation, product innovation while continuously looking at efficiencies. In Slovakia, we introduced a recycling unit that was a big step forward. Anything we can do to avoid putting waste into landfill in favor of reusing or recycling – those are beneficial projects. The team there did a great job of implementing that unit professionally. I think we need to continue on other examples like that.

Last year and at the beginning of this year, we obtained EcoVadis® certification (click here to learn more). The certifications have been more stringent, more demanding, and that's good because the requirements are moving ahead with more expertise. We had a lot of programs, but we hadn’t put them together for a third-party certification. I think we have made a big step forward with pulling together our initiatives around environmental measures, ethics, labor, and human rights, as well as sustainable procurement, improving by more than 10%. That's a big achievement for the team, but also for the company.

As someone who lives and works in Europe, can you share your thoughts on any differences between Europe and the United States regarding sustainability?

I would say that in Europe, many Nordic countries are taking the lead. We see similar trends in the US, where states like California try to lead from a legislative standpoint. You may see there are different trends or different national legislations in Europe. Customers in one country may need to follow legislation or achieve certification at a national level. At JM, we must be aware of that and anticipate it. We ask ourselves, “How can we be better prepared to serve our customers so they can win in their marketplace?”

When you think about the opportunities around sustainability, what comes to mind?

I think we need to embrace sustainability every day and identify how it creates value through financial return, social impact, and environmental impact, but also how sustainability metrics and measures go into our business decisions and particularly our innovation roadmaps. On the energy front, we can improve and continue to develop efficient processes to adapt, for instance, to a changing energy mix and improve our recycled content in products. To do this, we’ll rely on innovation and sourcing and go in a direction where they are aligned as much as possible.

When I think about sustainability, there's also the social aspect. I think people are certainly critical. We need to continue to drive diversity and inclusiveness programs. This helps to connect different departments and people within the company. It promotes a better work life and helps to attract younger talents to the organization. We can continue to create awareness that everybody in the company can have an impact. We can communicate ideas across our platforms and embrace ideas from our employees and suppliers. Suppliers can have a significant influence, and we need to ensure we are trying to align those ideas with our path forward.

What could JM customers take away from this interview?

In our Engineered Product division, we use words that I think are well chosen – “We make engineered products.” This means that they are quite often tailor-made for our customers, which means that we strive to be close to our customers and really understand the direction they're going in. Today, our customers are navigating an increasingly complex environment with more compliance questions and a need to develop expertise on those issues. At the same time, they want to build and innovate new and sustainable products.

At JM, our vision is to Build a Better Tomorrow. We want to be a thoughtful partner who understands the needs of our customers and the younger generation – the future generation. We want to develop durable products with a lower CO2 impact on the planet alongside our customers. Innovation is key. We know there's always a balance to make sure that what has been developed can be commercialized effectively both for our customers and then, of course, for JM. If our customers win in a marketplace with more sustainable products, we can follow them. But more than following is innovating within a true relationship of being the preferred supplier. We want to play into new developments our customers may have. I’m not saying that all developments will be truly around sustainability, but there is certainly a significant portion of it that will be related to sustainability, and we must be prepared. What is important, as a preferred supplier, is providing cost-competitive and transparent solutions with good service and information flow that demonstrates that we are a true partner in their future winning proposition. To do that, there are a lot of avenues to explore with our customers as well as in aligning our suppliers and partners. When we are aligned, we see the best benefits from innovation as well as the efforts behind it. We can help make customer solutions more durable and, therefore, more sustainable. I think we can win. I think we can build a better tomorrow for future generations.

-

Engineered Products

-

Engineered Products

-

Engineered Products

-

Engineered Products

-

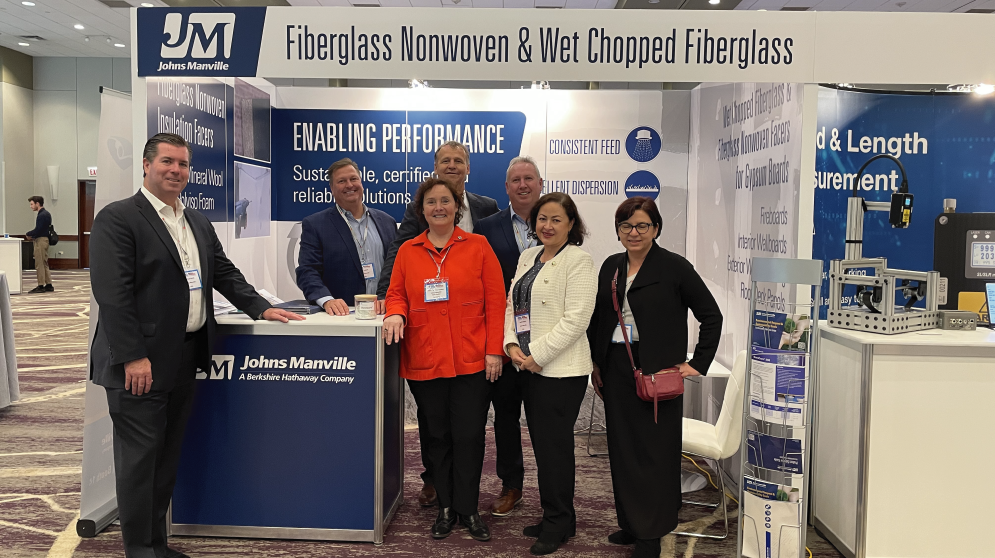

Engineered ProductsIndustry Insights, Sustainable Innovations, and Market Adaptability: A Comprehensive Overview from the Global Gypsum & Insulation Conference 2023

-

CommunityInternational Glass Artist Blends Illusion and Reality Using Johns Manville Materials

-

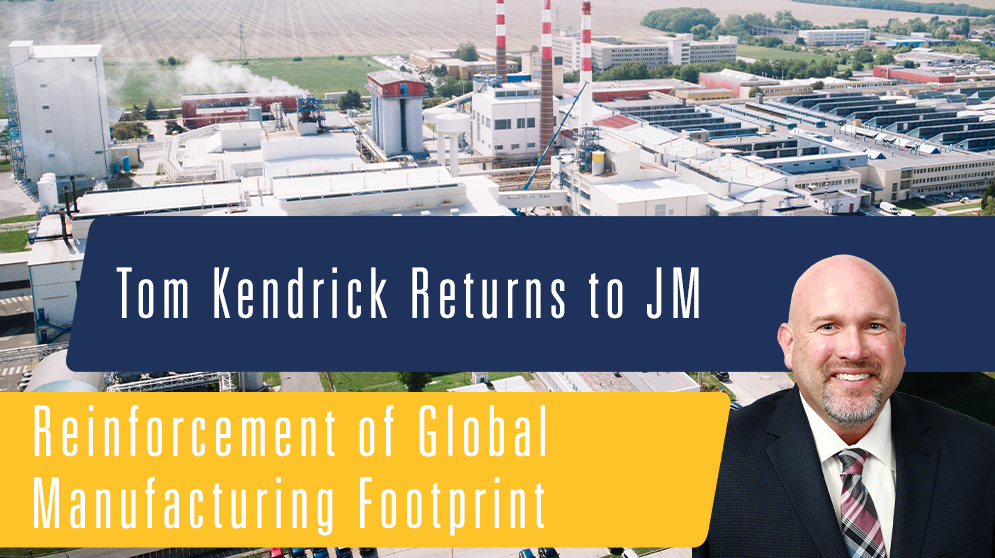

Engineered ProductsJM Reinforces Global Manufacturing Footprint as Tom Kendrick Returns as Global Fiberglass Commercial Director

-

Engineered Products