PVC Roofing Systems

PVC Roofing Systems

- Family Description

-

Built to withstand the test of time, our PVC roofing membranes are made to resist the toughest weather conditions and chemicals.

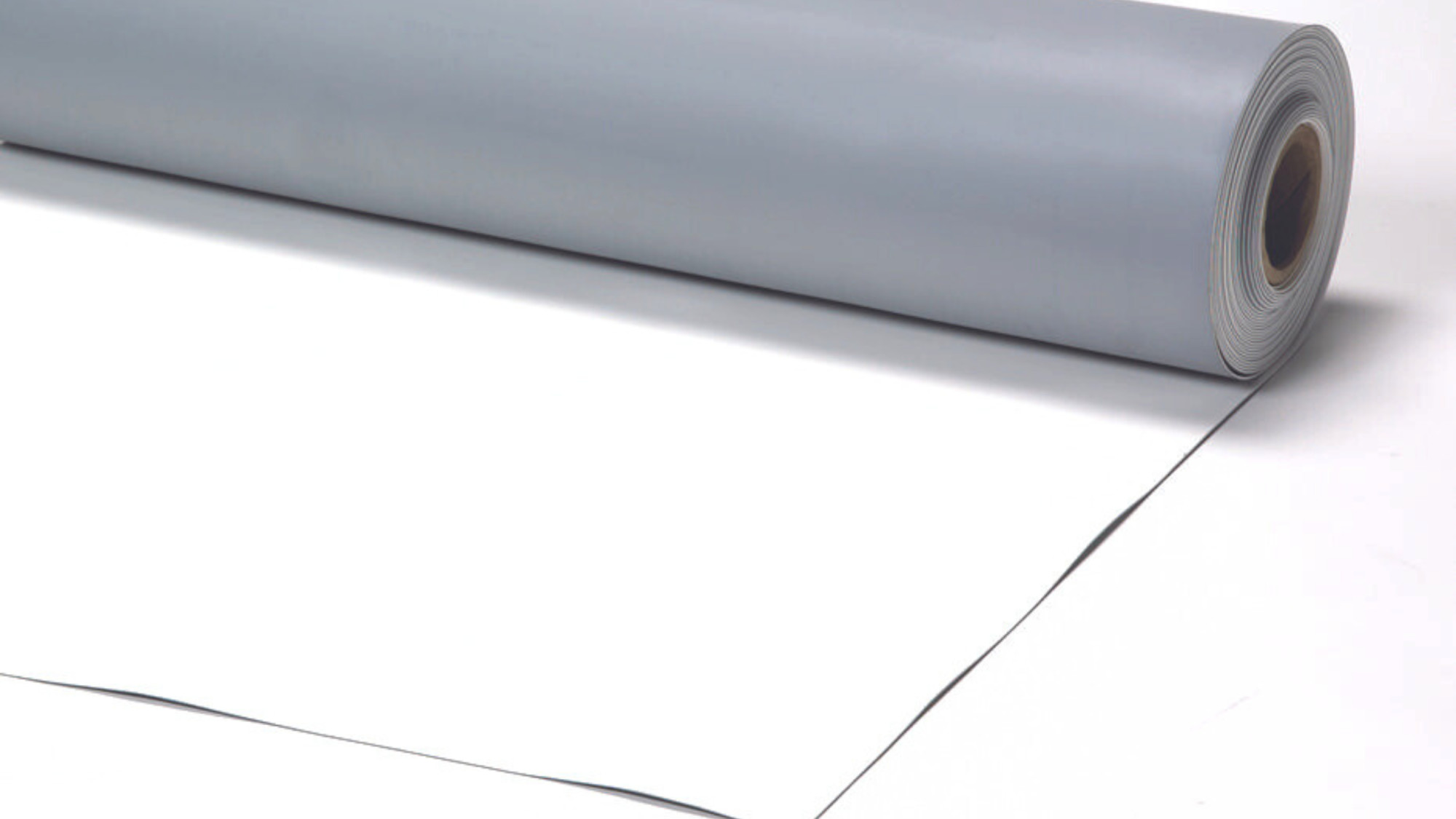

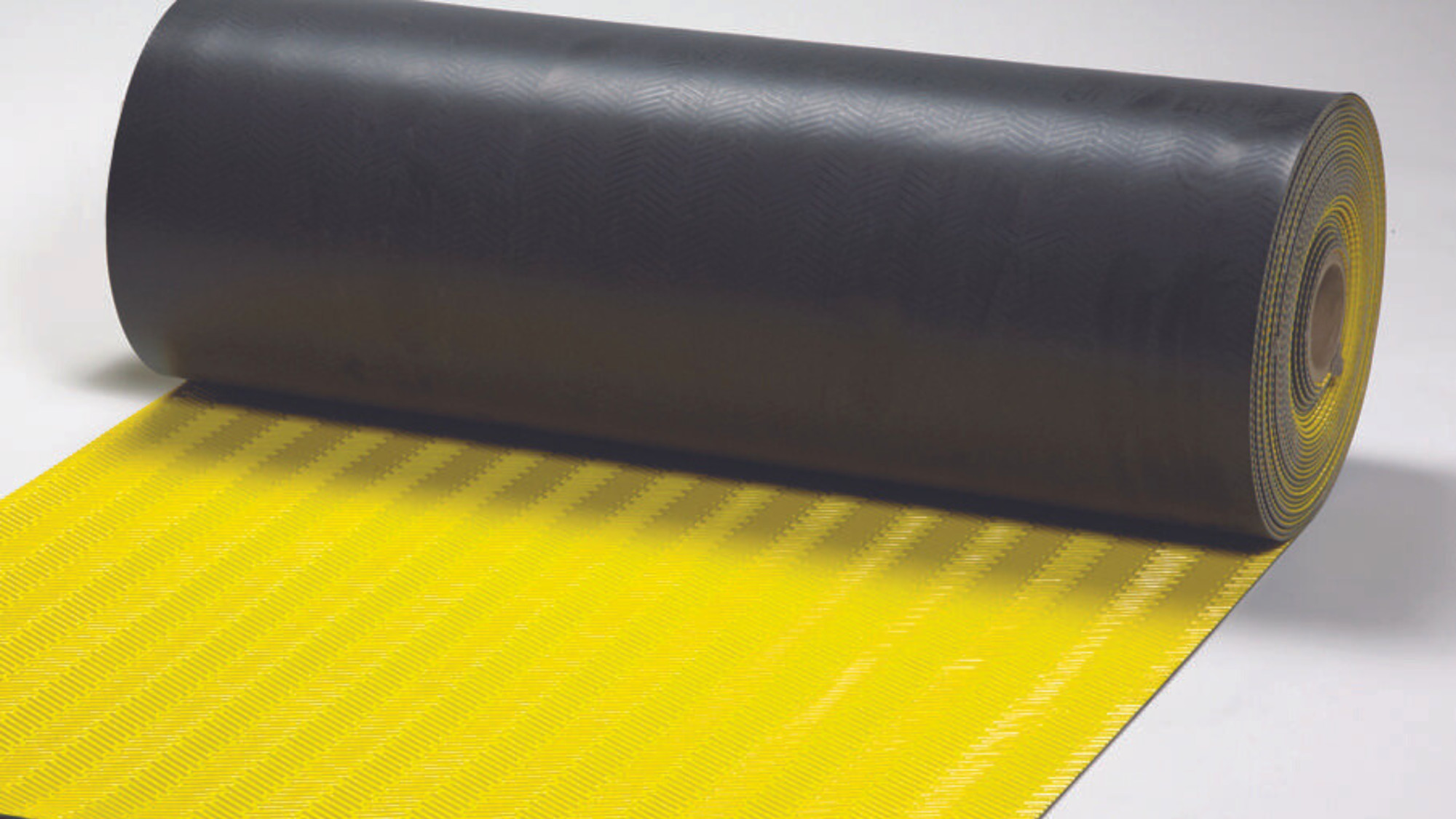

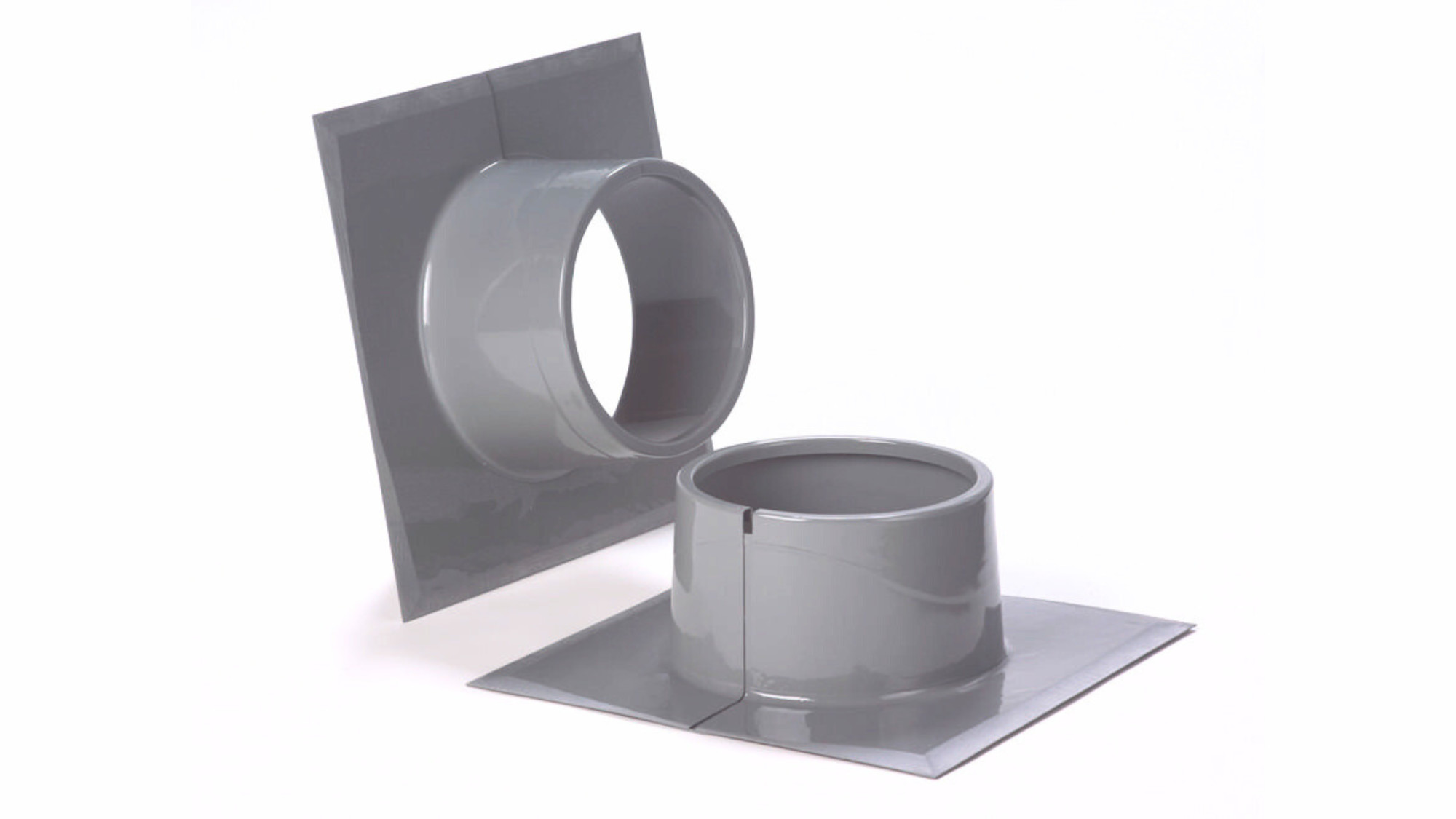

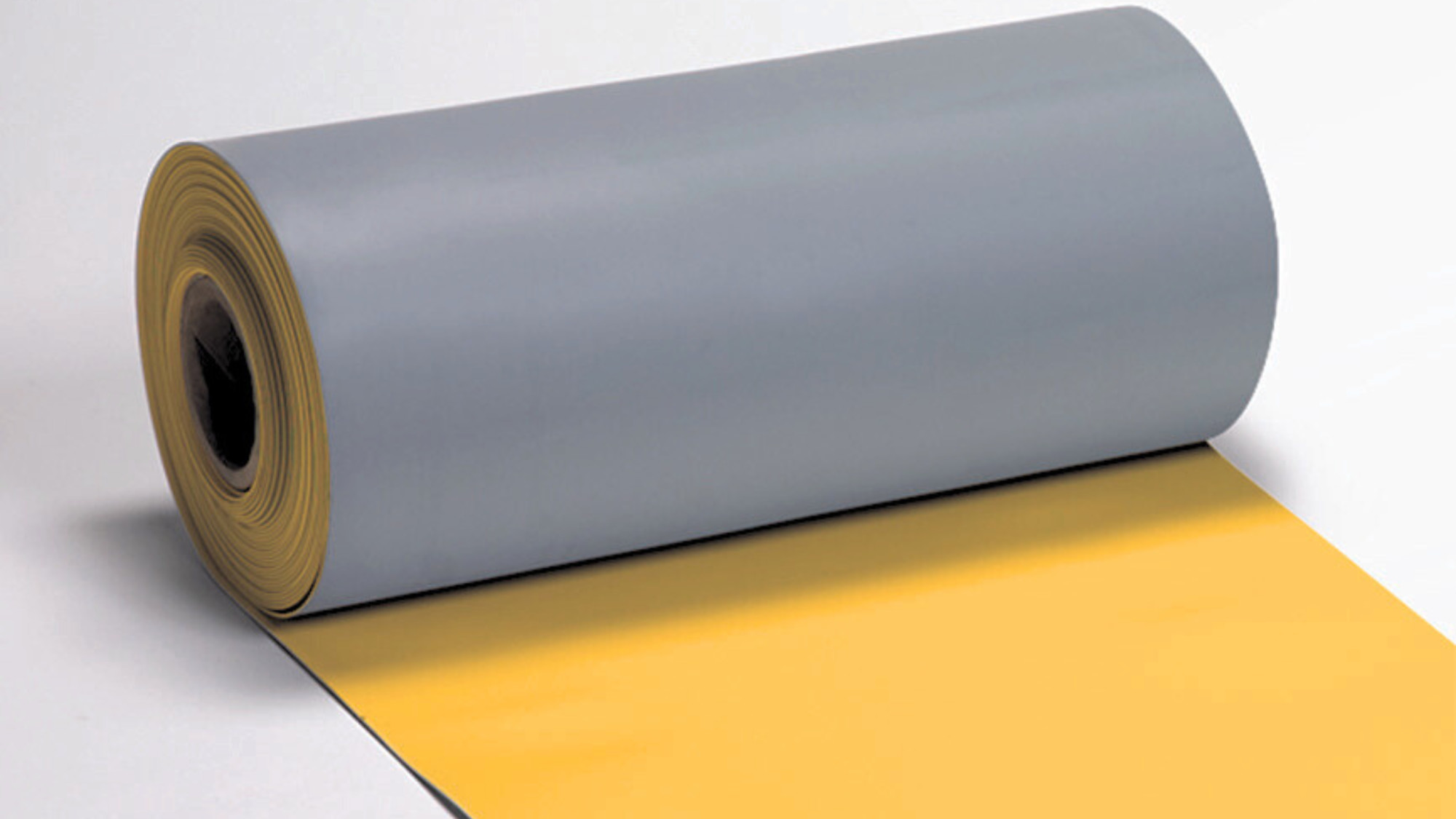

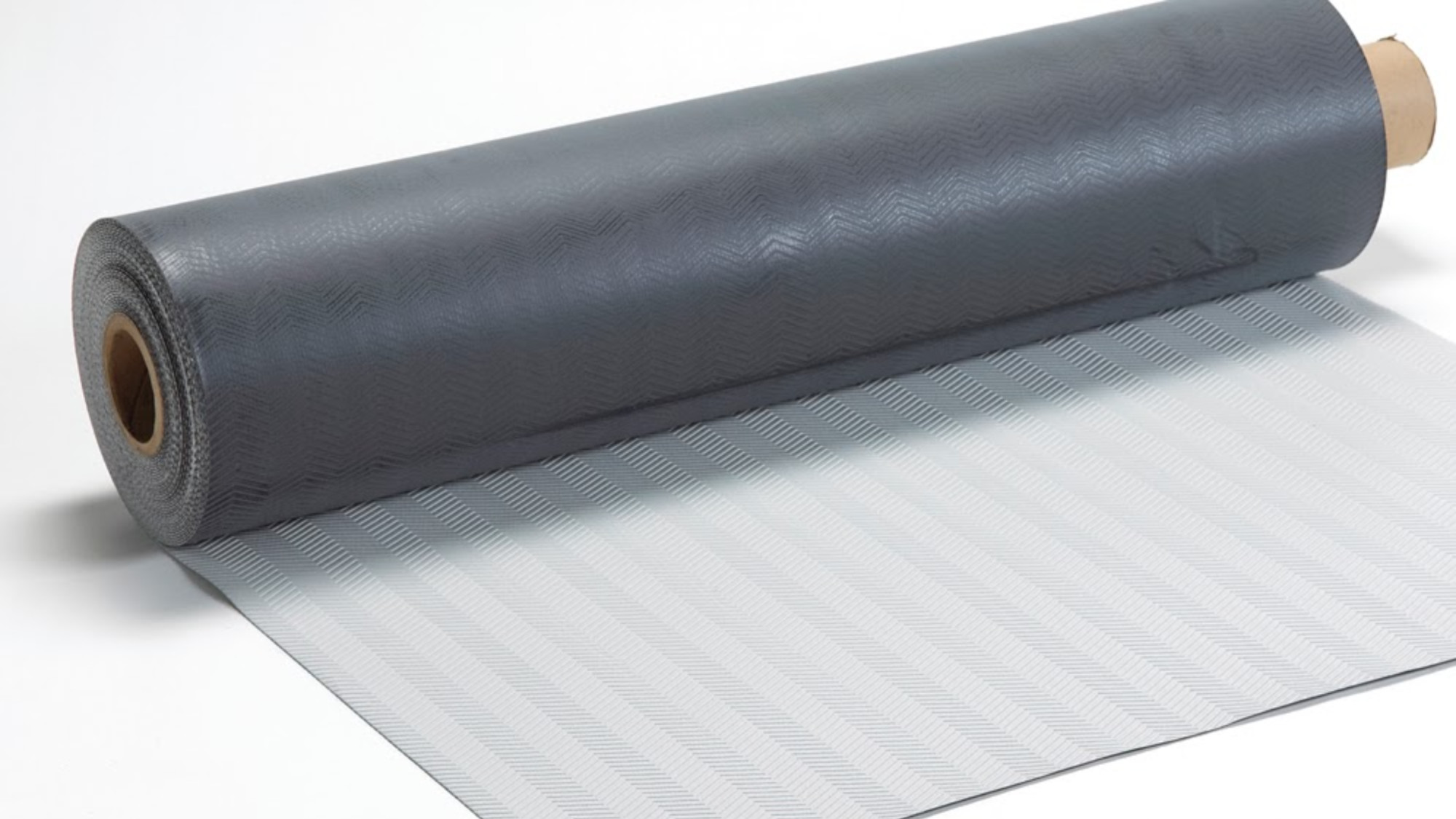

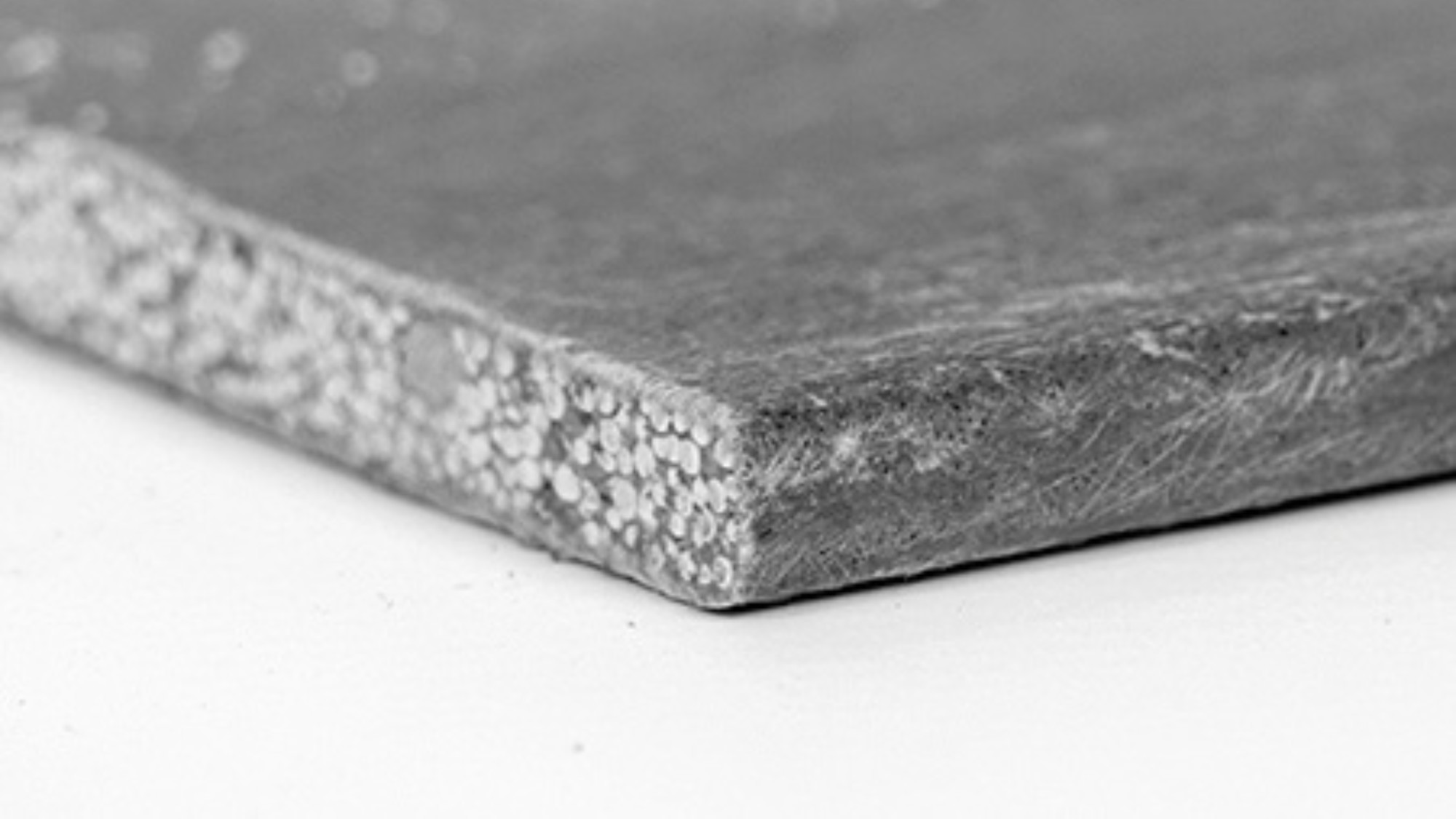

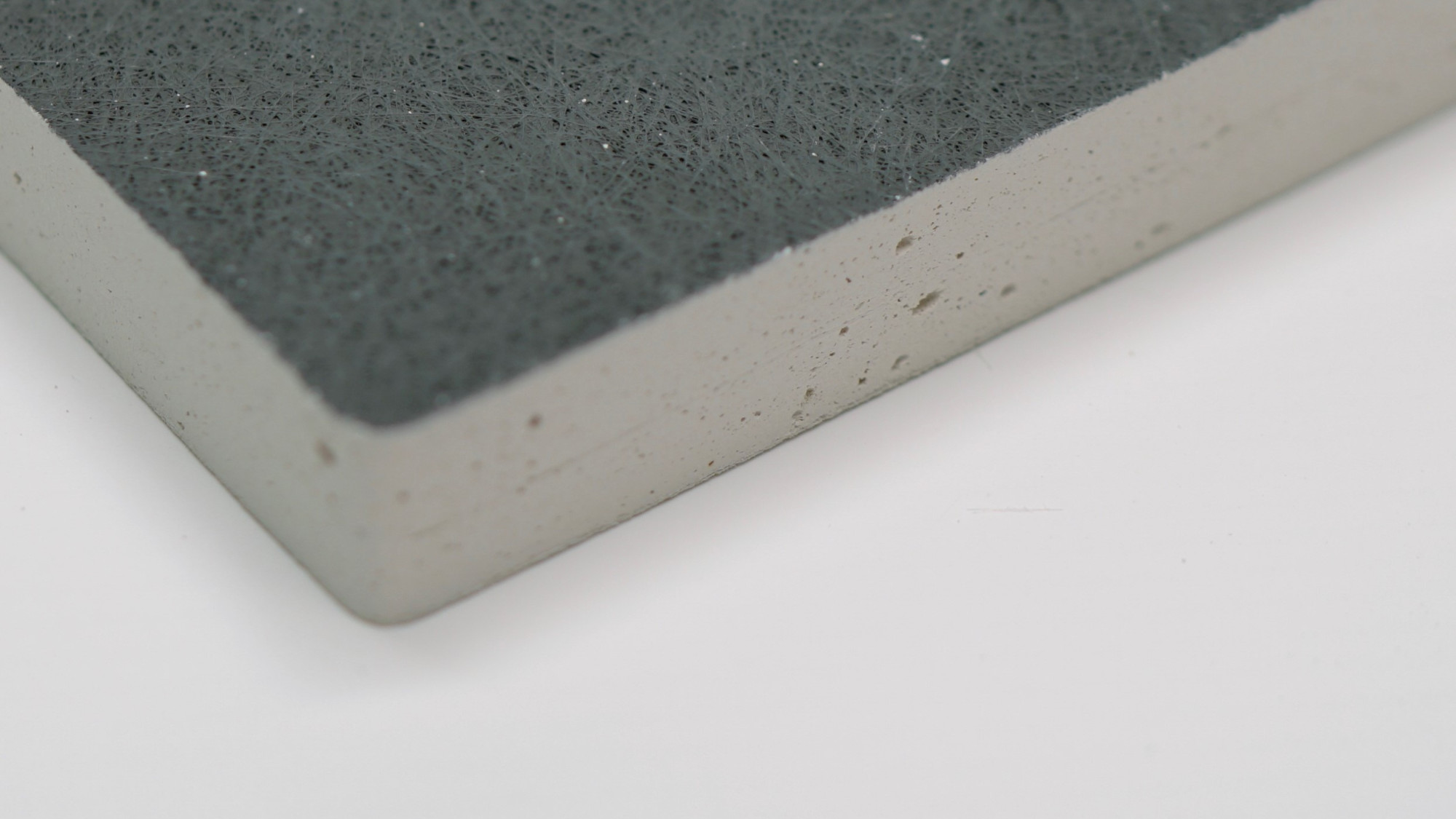

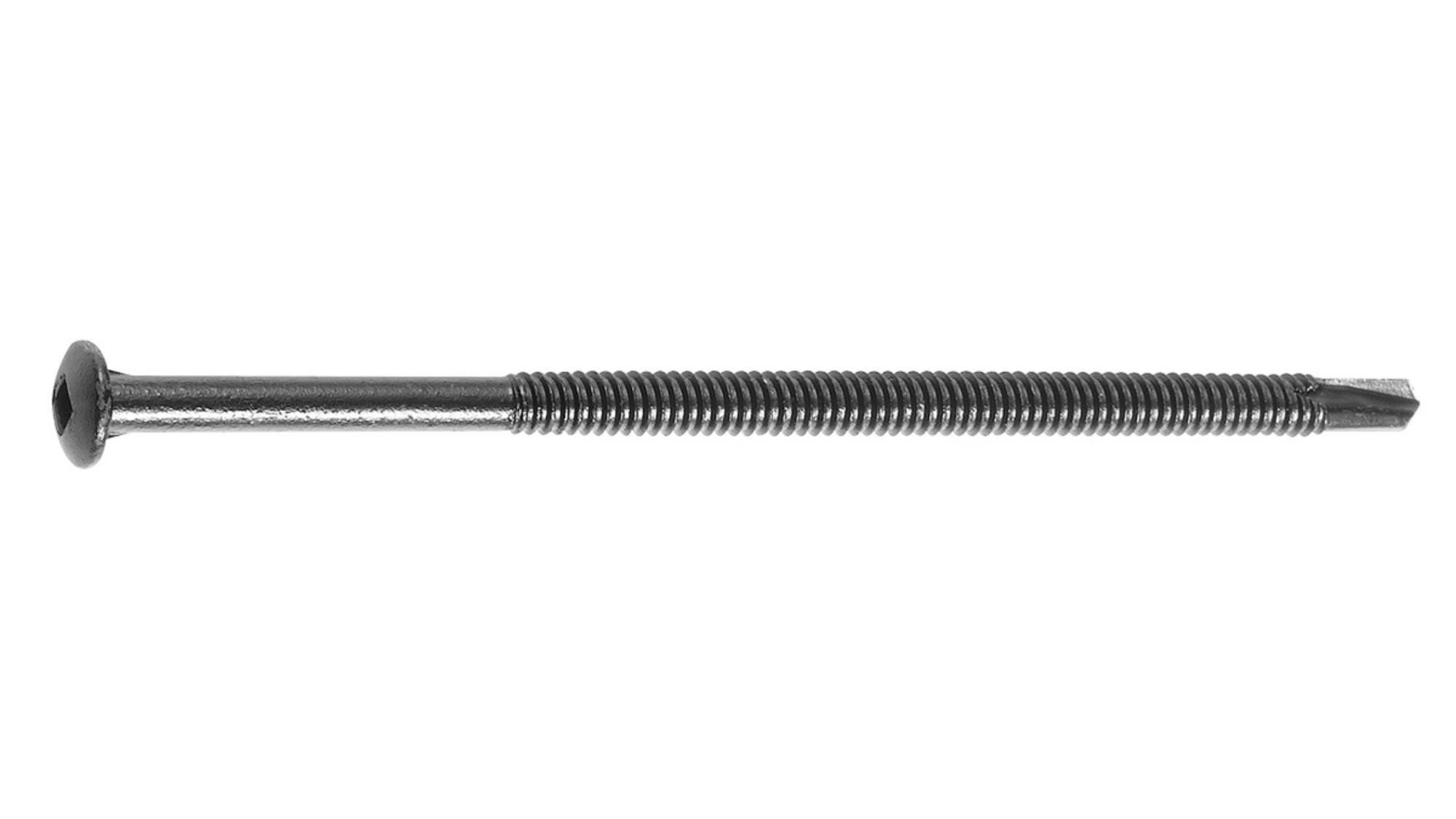

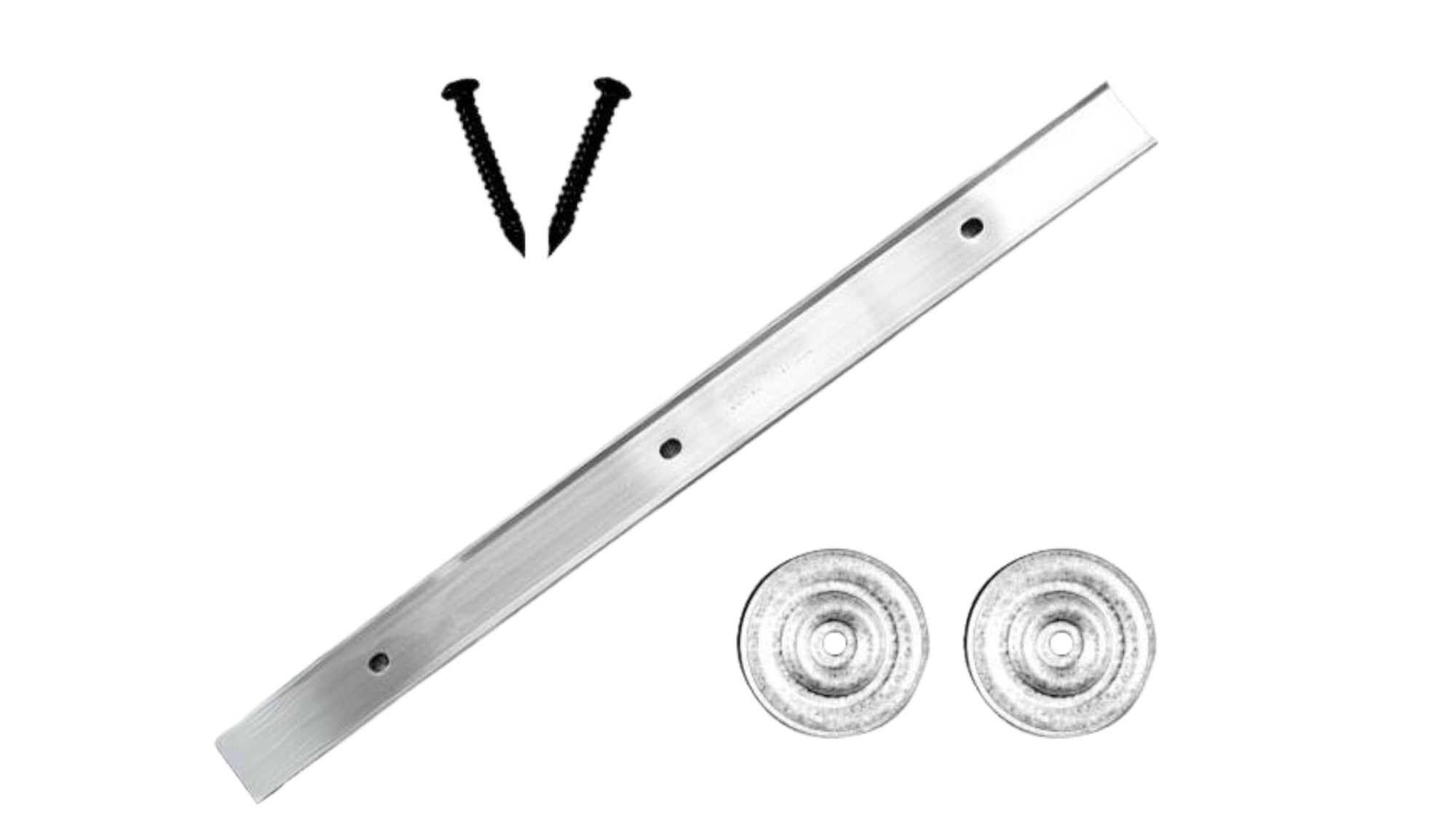

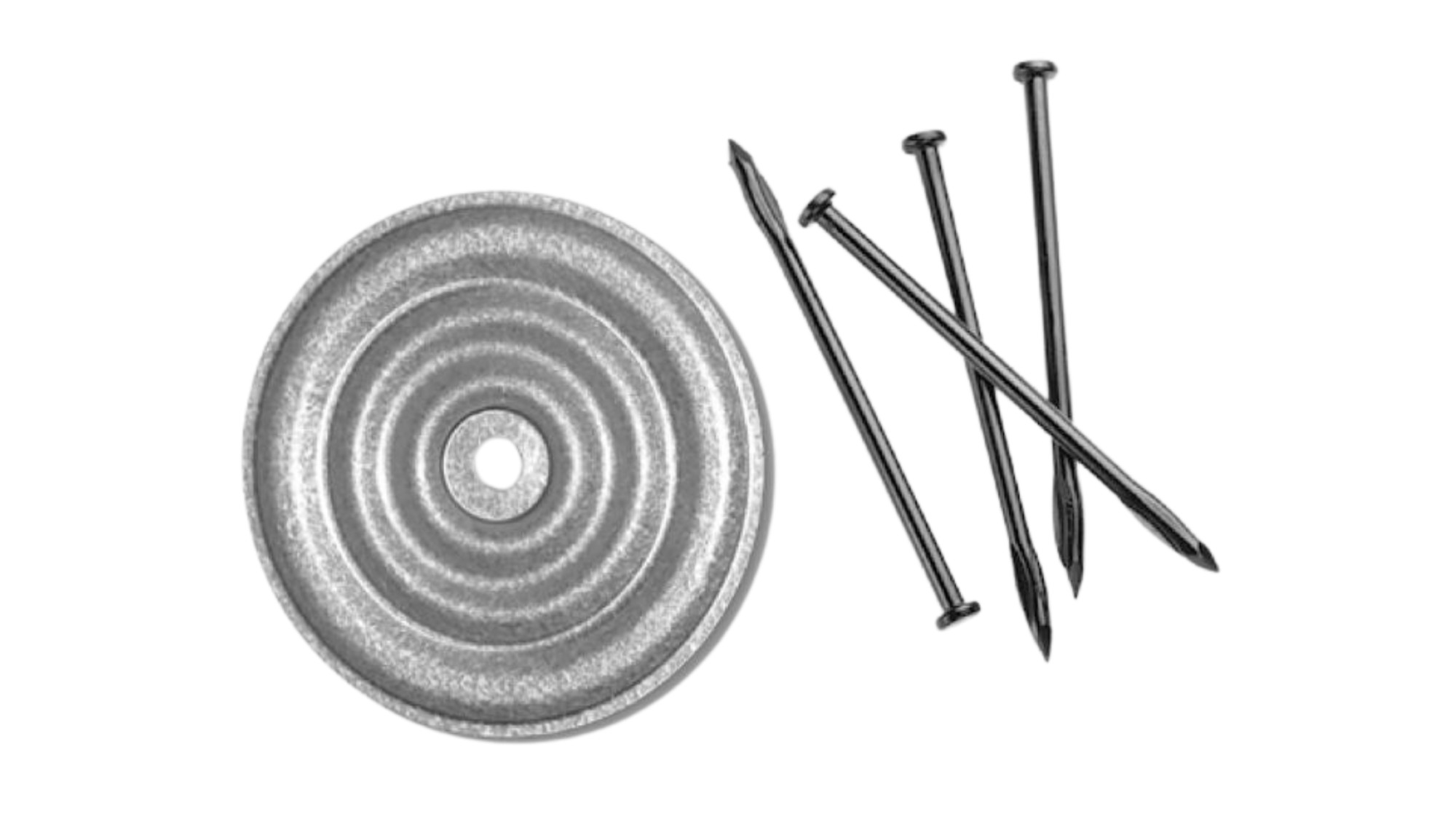

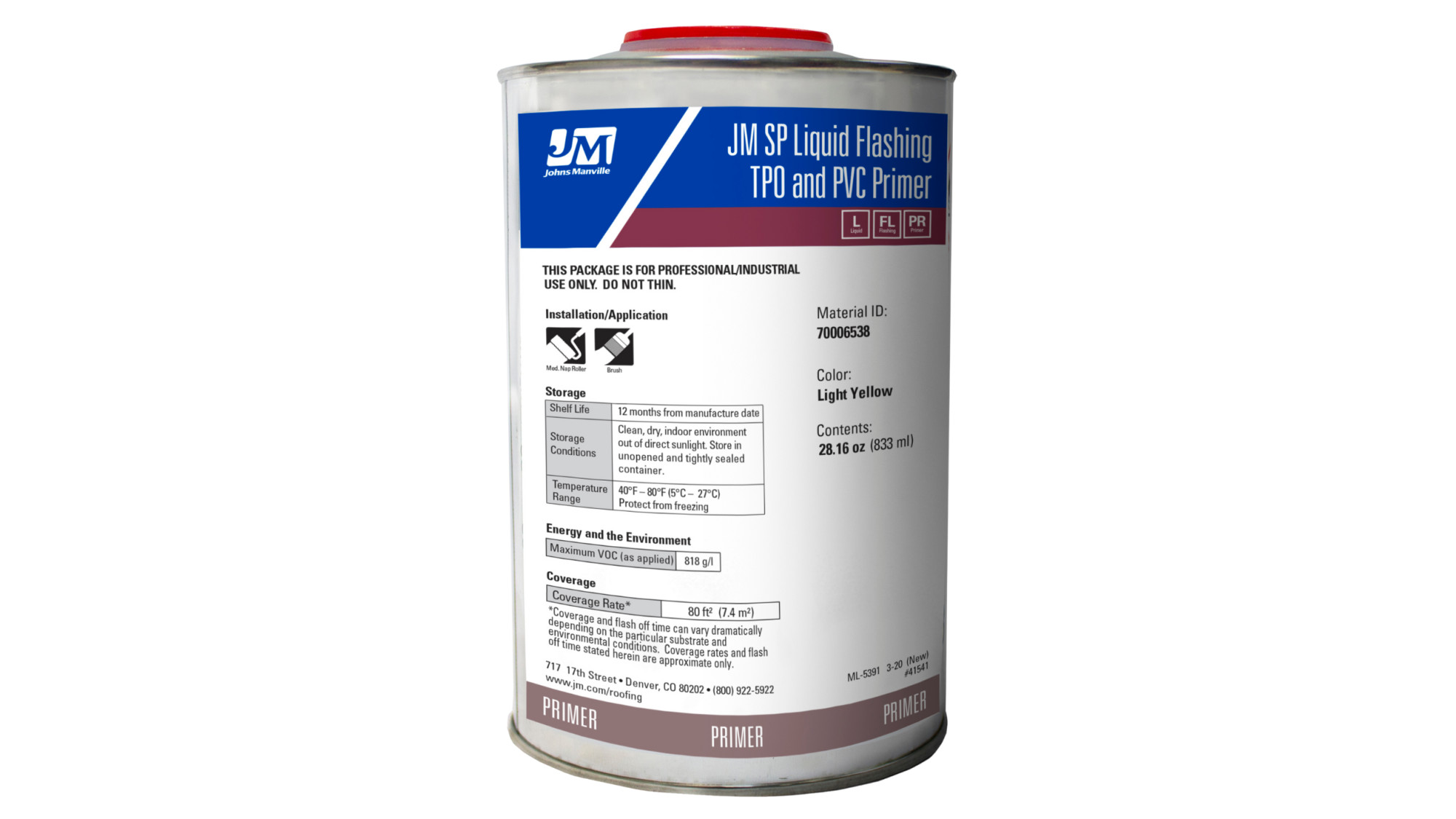

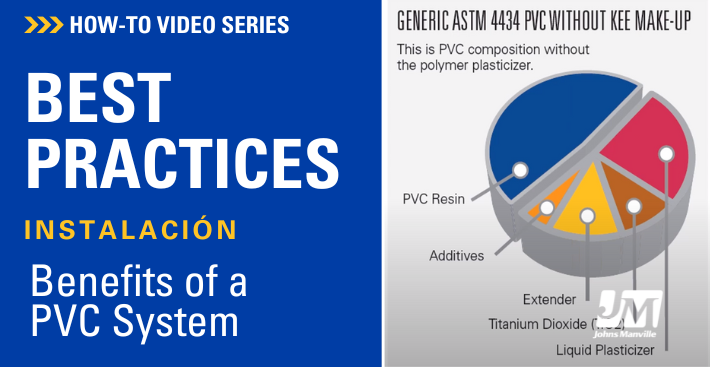

JM PVC with Dow Elvaloy® KEE and JM PVC SD Plus thermoplastic roofing membranes are manufactured using an ultraviolet-resistant polyvinyl chloride. Utilizing a polyester fabric reinforcement allows for systems to be both mechanically attached and adhered. PVC membranes deliver a pliable and durable sheet with excellent weathering characteristics and resistance to harsh chemicals and industrial pollutants.

Built to withstand the test of time, our PVC roofing membranes are made to resist the toughest weather conditions and chemicals.

JM PVC with Dow Elvaloy® KEE and JM PVC SD Plus thermoplastic roofing membranes are manufactured using an ultraviolet-resistant polyvinyl chloride. Utilizing a polyester fabric reinforcement allows for systems to be both mechanically attached and adhered. PVC membranes deliver a pliable and durable sheet with excellent weathering characteristics and resistance to harsh chemicals and industrial pollutants.