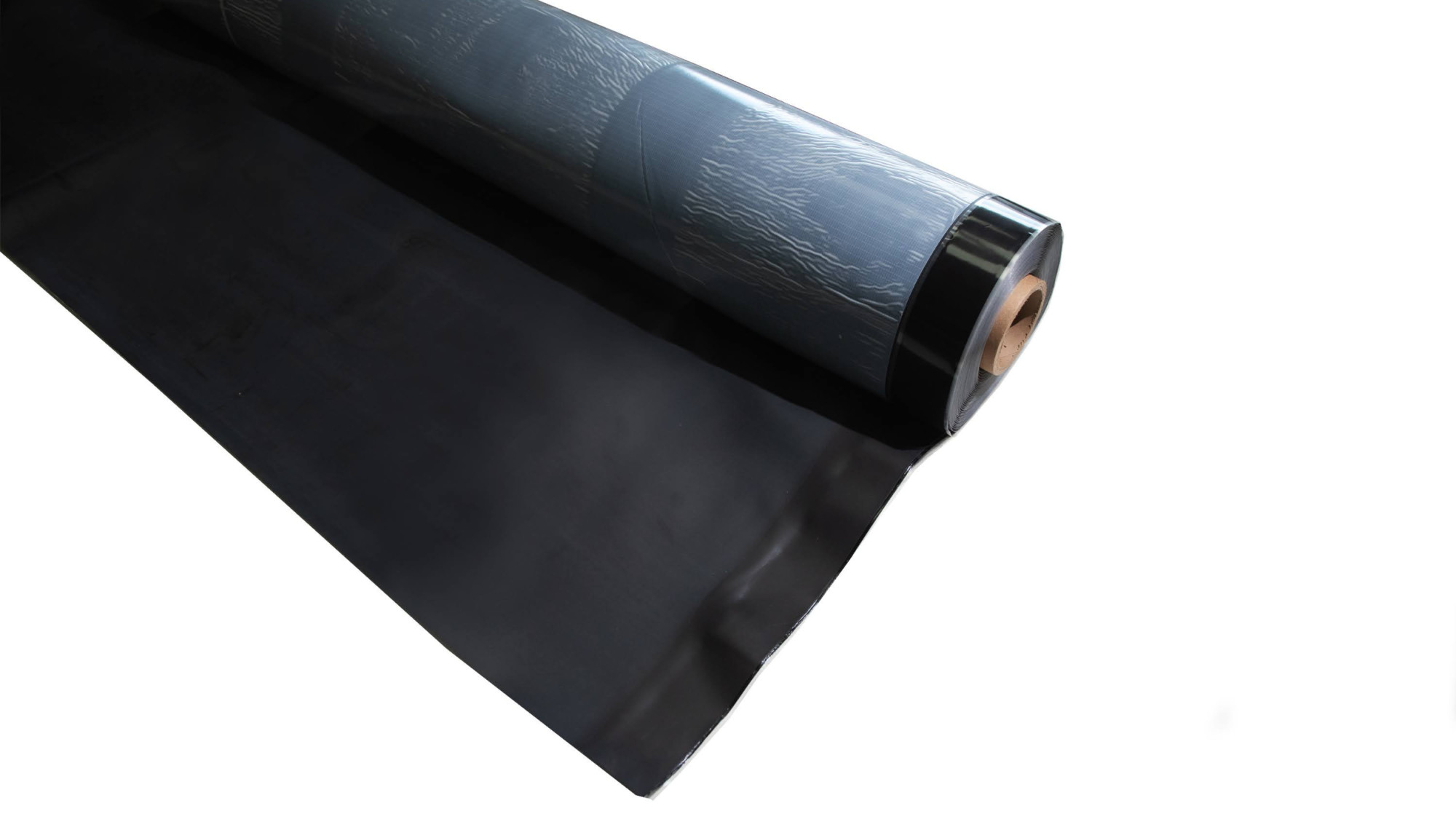

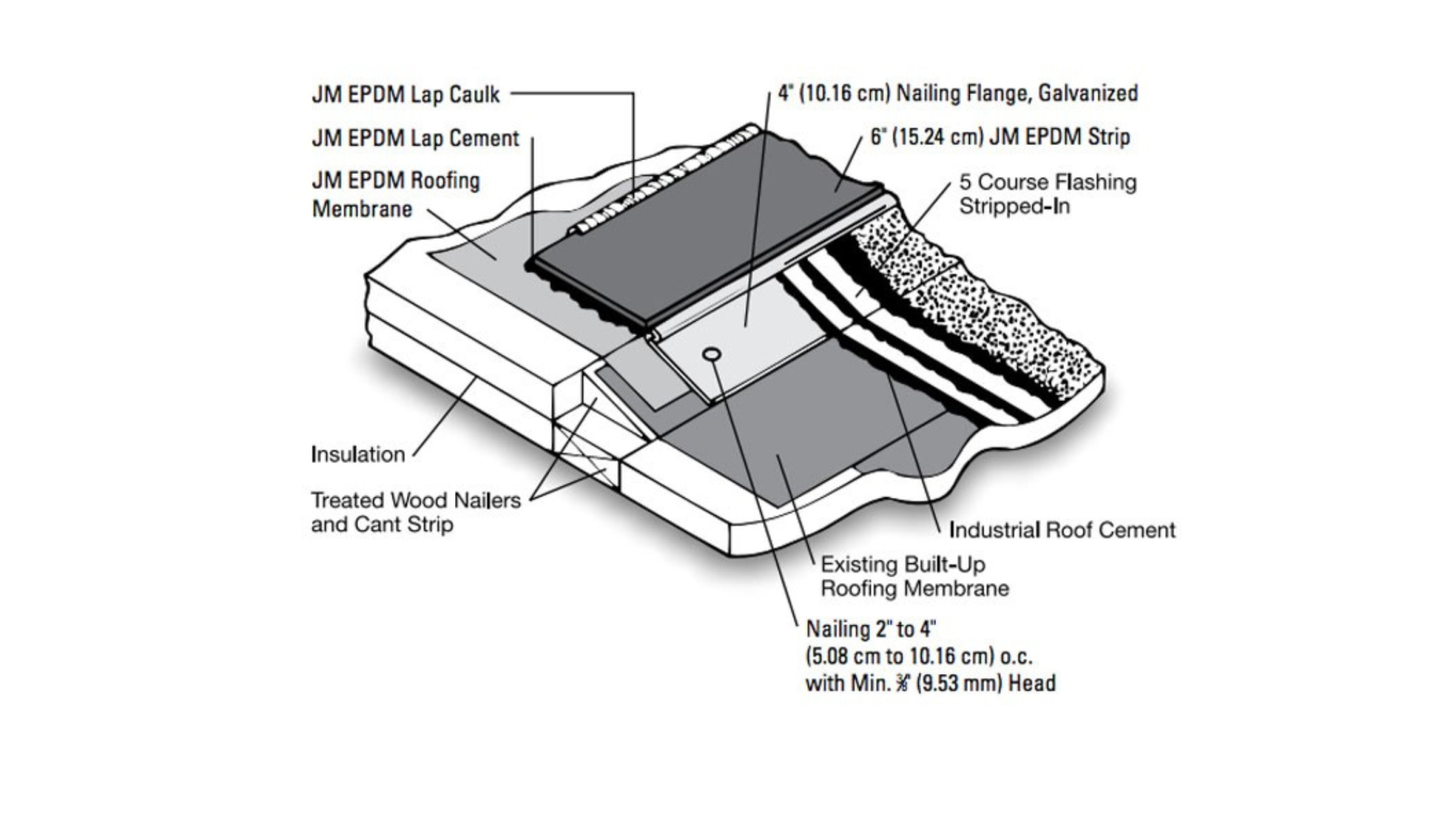

EPDM Roofing Systems

- Family Description

-

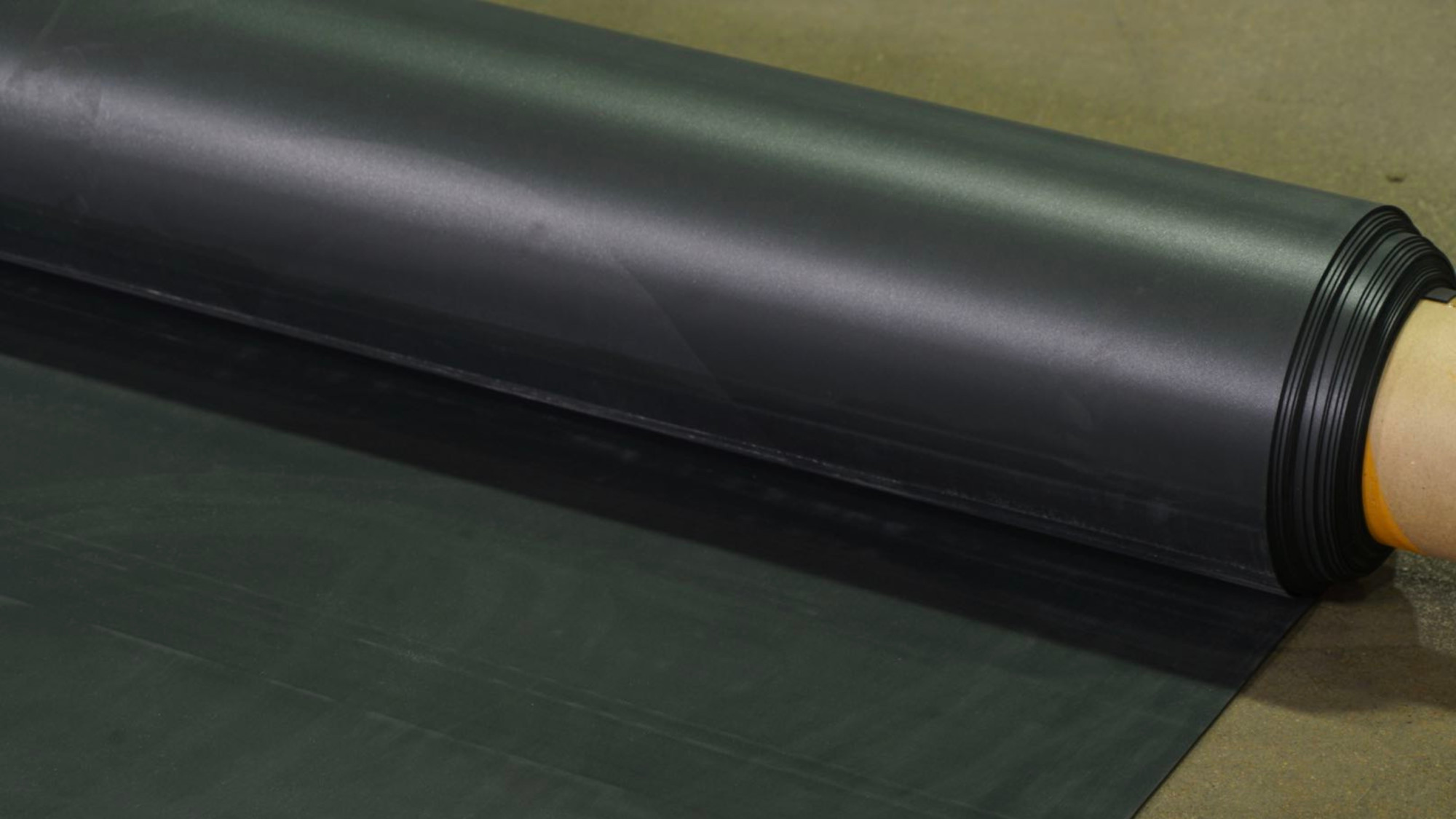

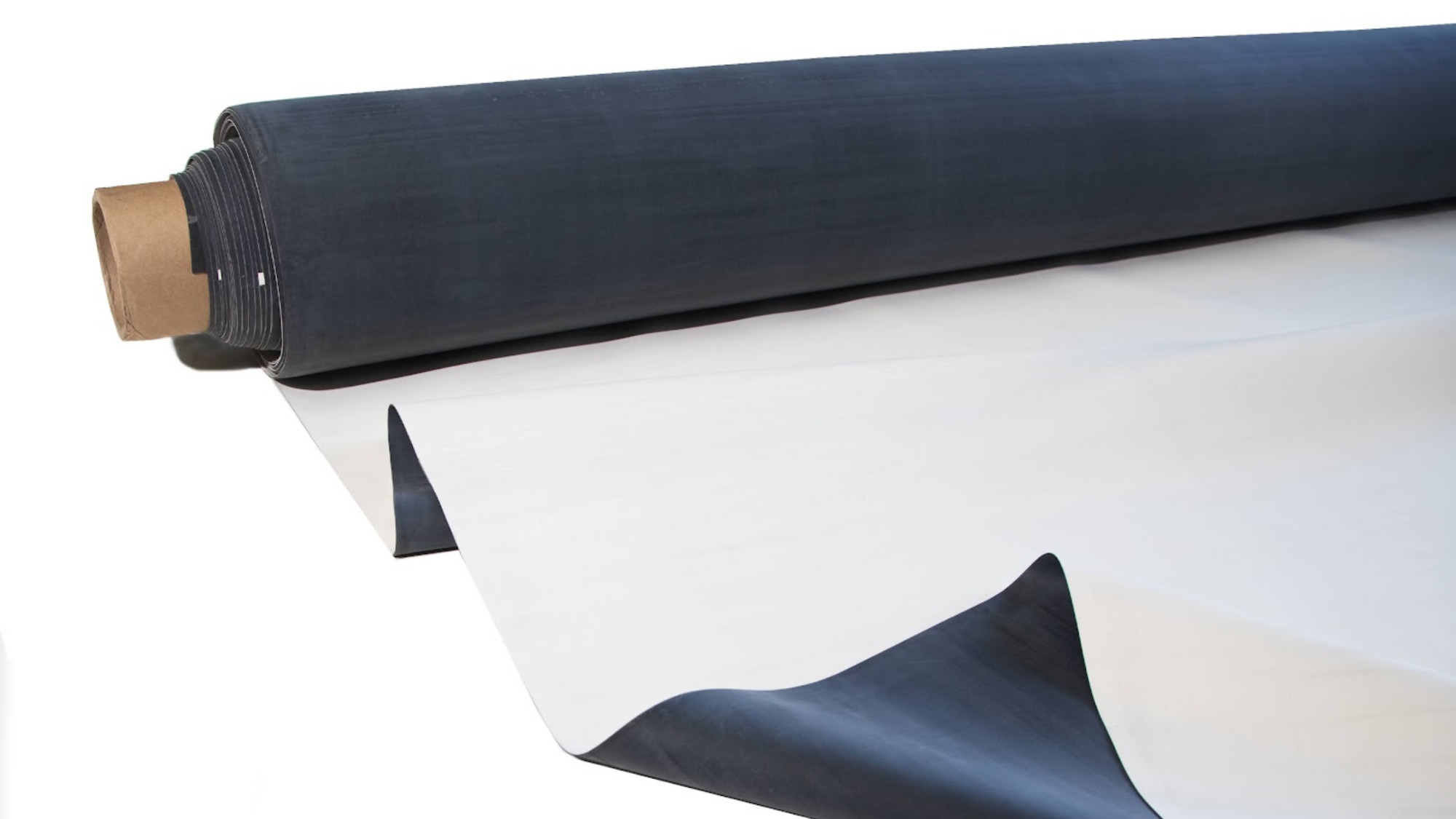

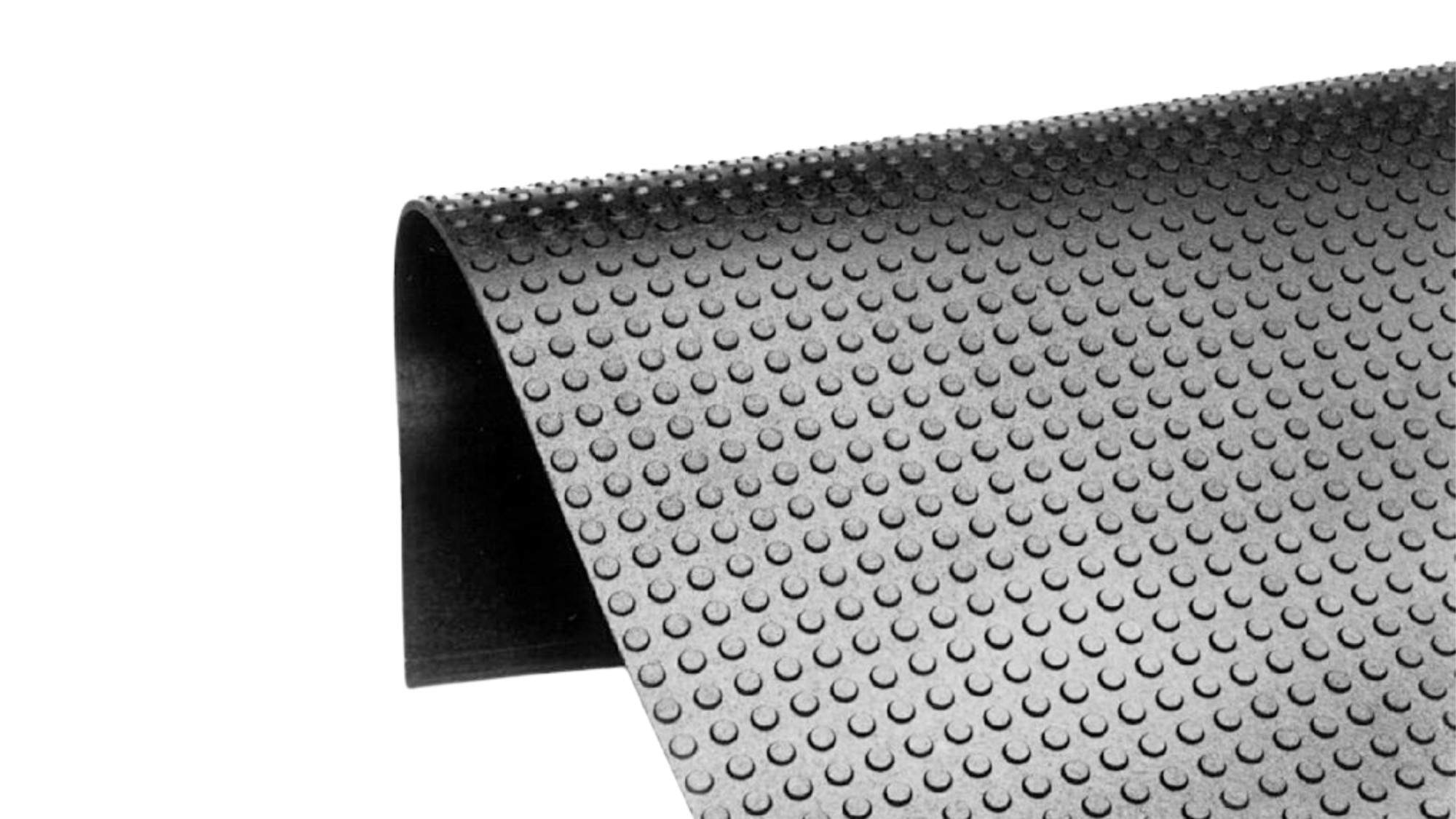

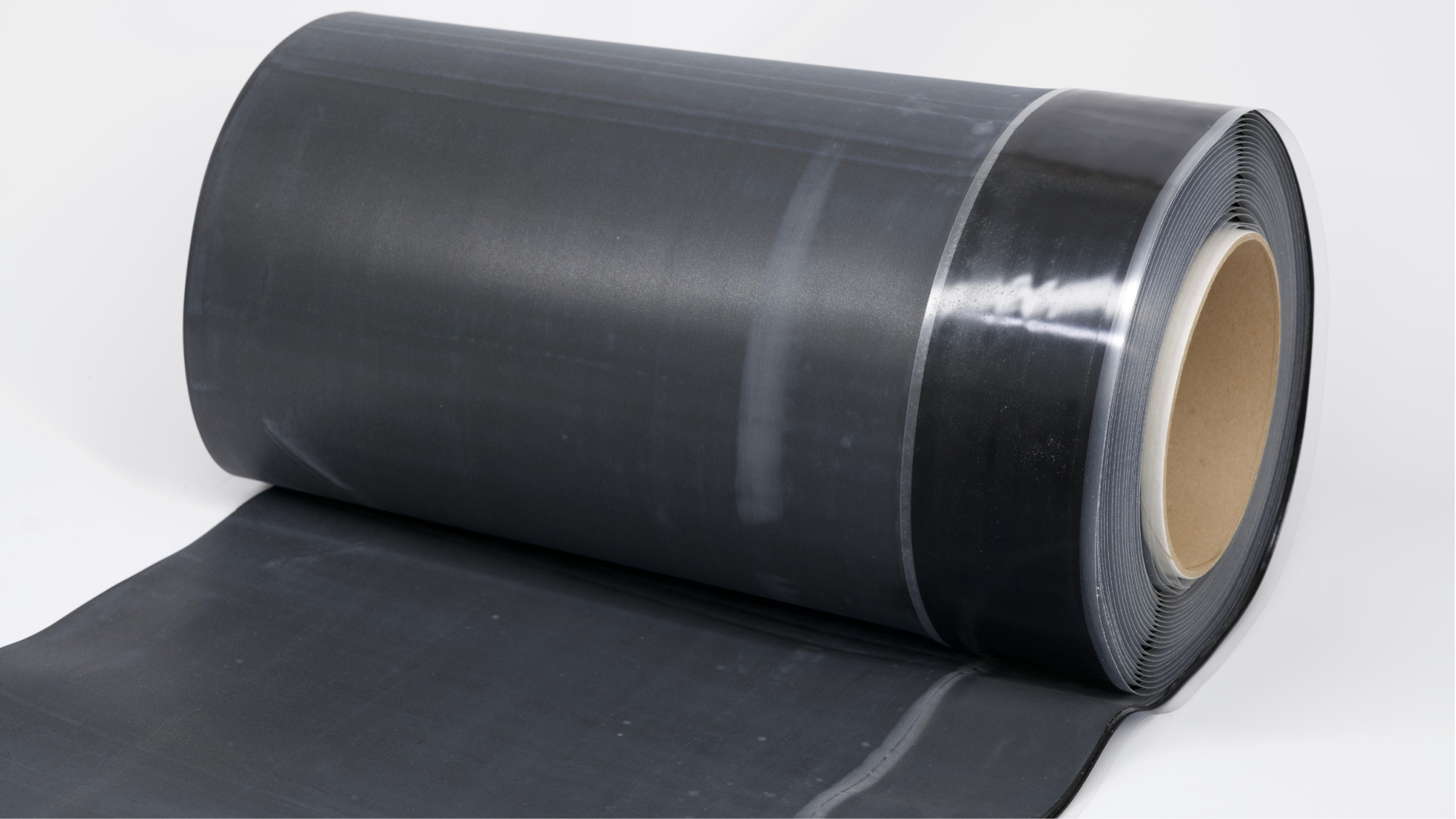

With superior durability and flexibility, EPDM is a smart roofing solution.

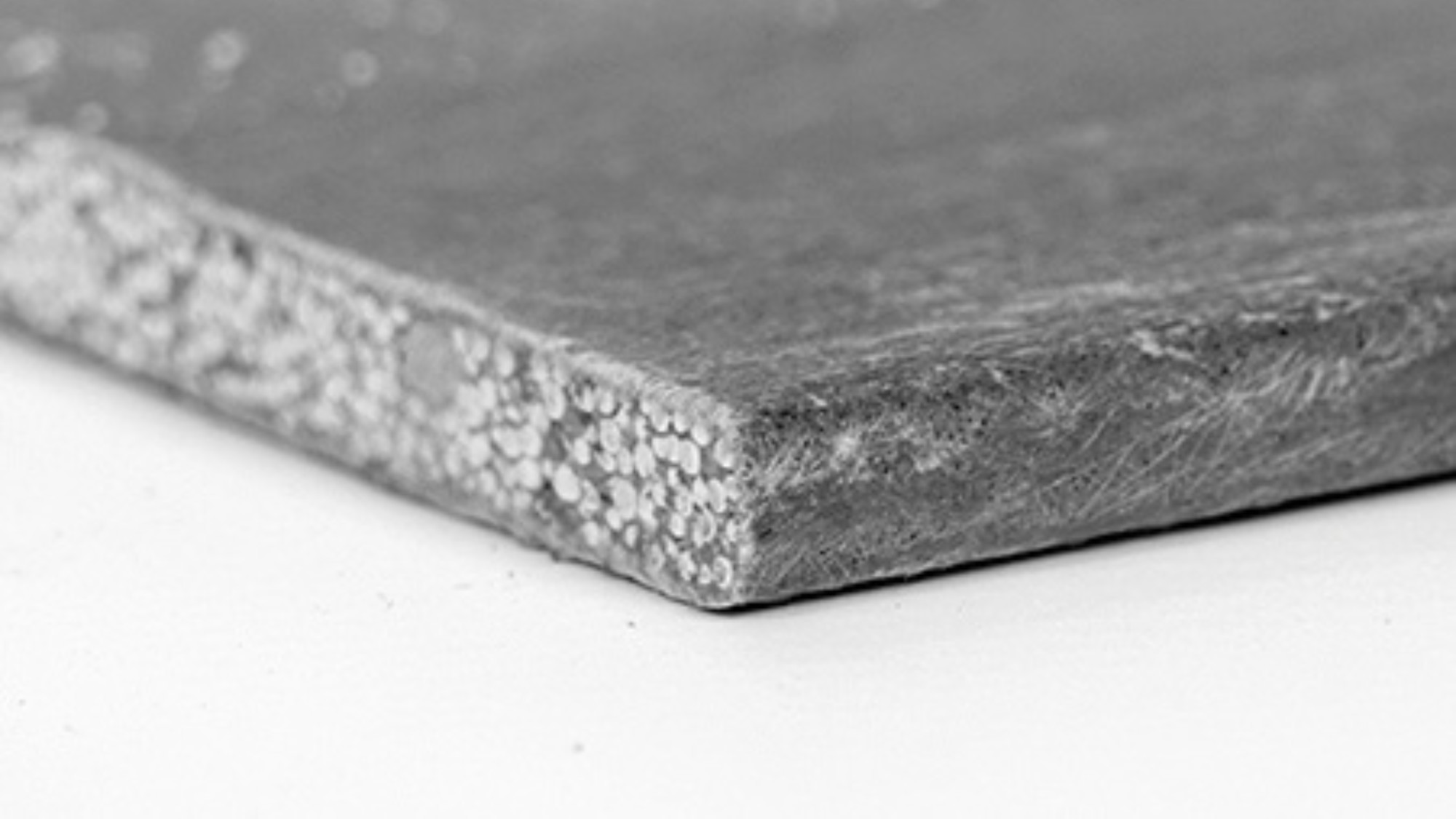

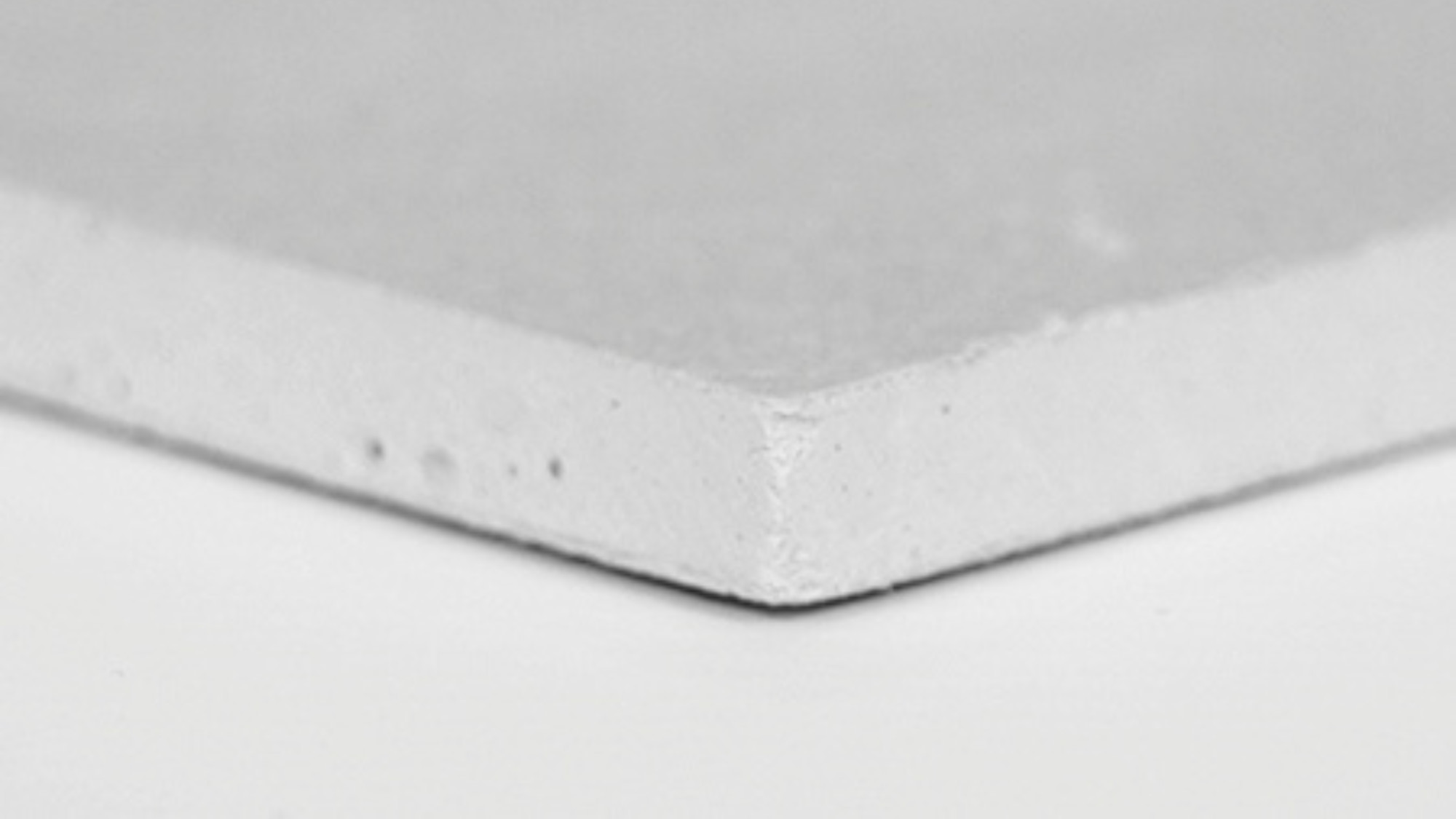

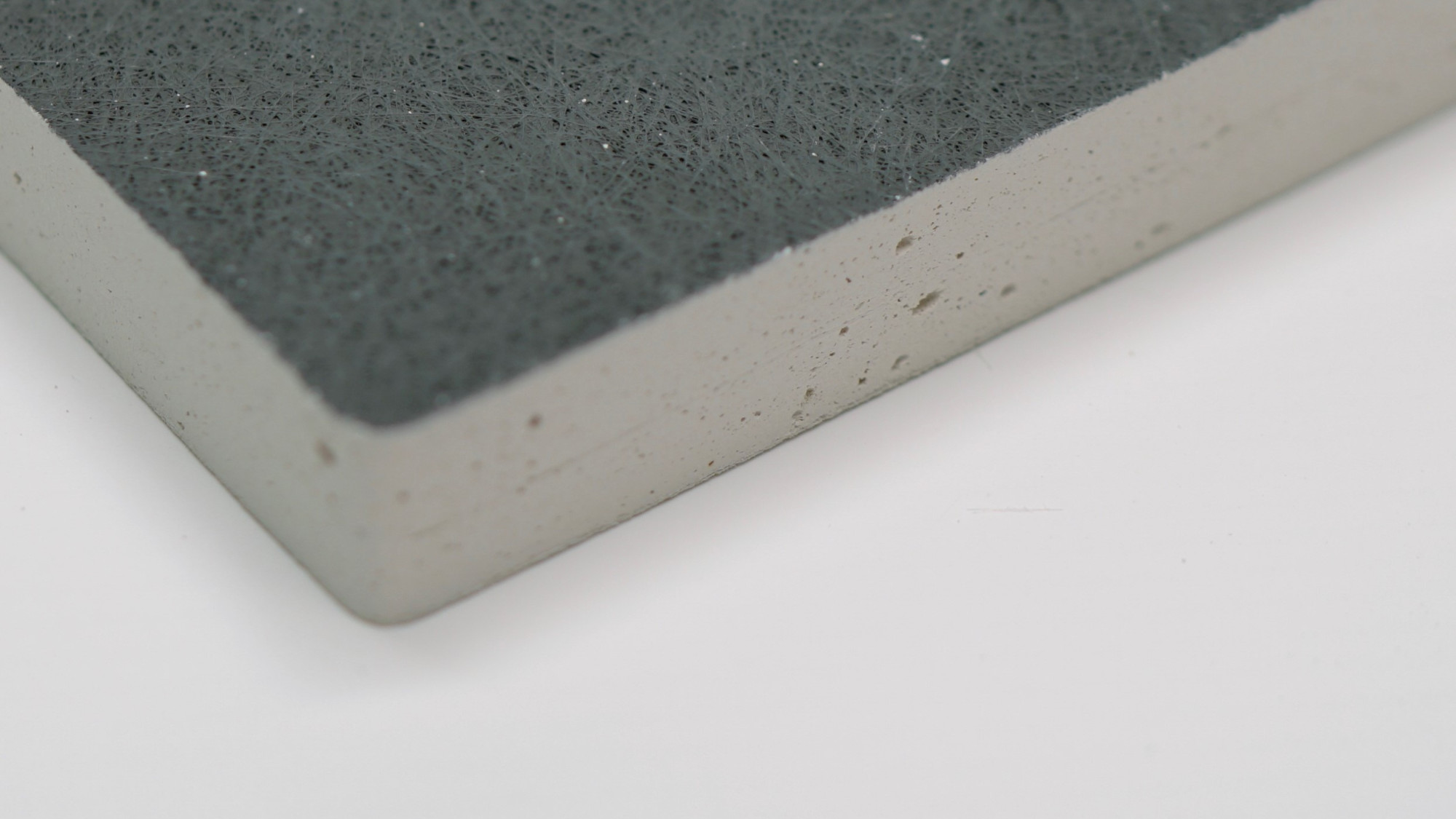

Our EPDM production facility is one of the world's most technologically advanced, allowing us to extrude our sheets instead of using the traditional calendering process.

Our EPDM is manufactured thicker with a more uniform surface finish. This advancement in manufacturing cleaner sheets requires less preparation to ensure a stronger bond during installation.

.png)