Sifting through the scraps and taking pieces of polyiso foam board to create a non-engineered slope on the top portion of a rooftop HVAC duct – there’s a much better (and easier!) way to get the appropriate angle to facilitate precipitation runoff.

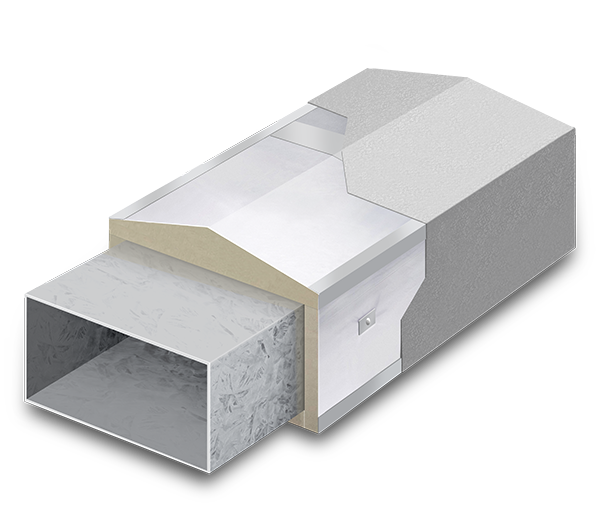

Customers talked about their struggles with the angle, about the issues they were having trying to engineer something themselves, and JM heard that unmet need. That’s how the tapered version of XSPECT® ISOfoam APF board was born.

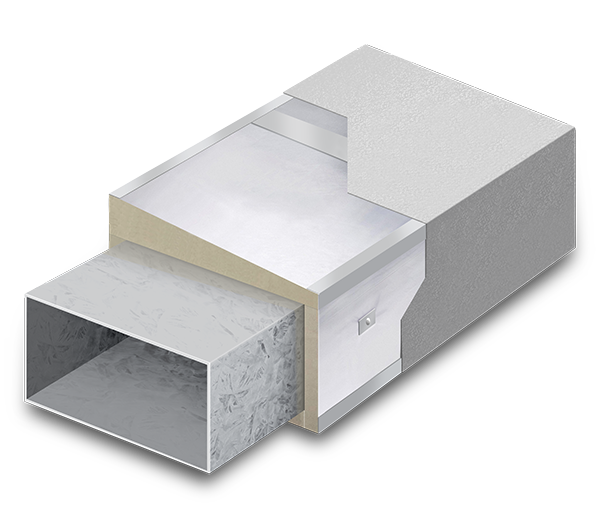

XSPECT is a durable, lightweight board insulation designed to simplify fabrication and installation on things like rooftop ducts, exterior tanks and more. Bonded to a foil facer on both sides, XSPECT is a closed cell polyisocyanurate foam core board. The foil facer acts as a vapor retarder and helps create a tightly sealed system.

But, when it came to rooftop ducts, customers realized that they needed a slight slope on the top portion, so that snow could slide off or rain wouldn’t pool on top. Sloped boards facilitate precipitation runoff and move that moisture away from the duct quickly.

The most common on-the-fly fix was contractors taking scraps from the job and pushing them under the edge of one side to create a sloped top. Not ideal.

“This is time consuming and it’s inconsistent,” said JM Product Manager Nicole Miller. “There’s no mathematical formula there, no specific slope because it’s eyeballed. Plus, it can create gaps under the insulation which can negate the effectiveness of insulation or introduce additional opportunities for condensation or moisture.”

JM roofing already makes tapered boards, so sometimes contractors would go to a roofing distributor (or have tapered pieces on hand) and use those pieces for slope. But that product only comes in 4-foot-by-4-foot sizes, not ideal for 8-foot duct runs, plus the facer is not the same as that of XSPECT, and not specifically designed for rooftop ducts.

Enter JM’s innovative insulation team. With the roofing product already on the market as a jumping off point, Tapered XSPECT came to life quickly.

The tapered boards are all 4-feet-by-8-feet in size and come in different thicknesses for specific climate zones/R-value requirements. XSPECT flat and tapered boards are available in single pallets that can be mixed with other Johns Manville HVAC and Mechanical products as well as full truckloads that can be delivered directly to jobsites. Incorporating them into a system is easy, saves time and makes for better installations – a win-win-win.

“Tapered XSPECT gives contractors the ability to purchase all their materials for an exterior roof top duct system, both tapered and flat, from a mechanical distributor, instead of needing to go to a roofing distributor too. Streamlined purchasing,” Miller said. “There’s less labor involved since field fabricators don’t have to create their own pitches, and this way the quality is also consistent.”

To learn more about XSPECT APF Isofoam Board in Rooftop Applications, visit our resource page.