We know we are better when we work together.

Although the COVID-19 pandemic requires physical distancing, JM employees ― or JMers, as we like to say ― are adapting and rallying to find creative ways to support one another and our communities.

From sewing handmade masks to helping local businesses and healthcare workers to remembering the simple things like saying “thank you” to those who have sacrificed so much, JMers are going the #JMextraMile.

Sewing Masks for Healthcare Workers, Firefighters and Each Other

Limited quantities of Personal Protective Equipment (PPE) burdened first responders and medical workers in the early stages of the pandemic. N95 respirators and surgical masks were in short supply, forcing organizations across the country to ration them. JM employees and their loved ones rose to the occasion by sewing handmade masks after working hours or during lunch breaks.

Inspector Packer Lauri Neilson, who has worked at JM’s Defiance, Ohio, plant for 22 years, filled mask orders for a local fire department and a nursing home, and she donated masks to family and friends who work in healthcare services.

Ross Sargent, a Process Engineer in our Insulation Systems plant in Cleburne, Texas, and his wife also made face masks out of cotton sheets, elastic and HVAC filter material for hospital workers in their community.

“We started making them after some friends who are nurses said there was a shortage at their hospital,” Sargent said.

Several JM employees and retirees also continue to supply masks to their coworkers across our locations.

Penning Letters to Say ‘Thank You’

Truck drivers are essential workers. Throughout the pandemic, they’ve sacrificed their own comfort and safety to deliver critical supplies, from medical gowns to loads of construction materials used to expand healthcare facilities.

Scottsboro, Alabama, Plant Manager Terry Couch has payed special attention to how truck drivers are recognized.

"A driver told me that he had to get a rush load of TPO to Florida to finish up an expansion wing of a hospital," Couch said.

TPO is a single-ply roofing membrane. And after hearing the driver’s story and countless other stories, Couch decided to write letters to thank these drivers on behalf of JM and our customers. Truck drivers who stop at the Scottsboro plant are personally greeted by Couch with an elbow bump, a letter to thank them for their service and an explanation of steps JM takes to provide a safe environment.

Recognizing Employees While Supporting Local Businesses

Once non-essential businesses began their phased re-openings, JMers connected with community leaders to learn what they could do to contribute to local economies. They started with the restaurant and food service industry, one of the hardest-hit industries amid the pandemic.

The idea was born after Waterville Plant Manager Matt Brown called Waterville Mayor Tim Pedro and asked him what Johns Manville could do to help the city beyond practicing safety protocols. The mayor asked that Brown and his team support takeout at local restaurants.

Cheryl Ball, Senior Purchaser, delivered lunches to the plant’s employees once a week for a month as a way to recognize them and support local restaurants in the Waterville community.

Ball orchestrated a system that involved ordering and timing the lunches for 600 employees working various shifts. She also personally picked up and delivered the food to employees.

“Employees looked forward to a weekly lunch,” Brown said. “And the feedback from the restaurants was that we were helping them make their payroll for the week. It was a great way for us to have community involvement amid the crisis.”

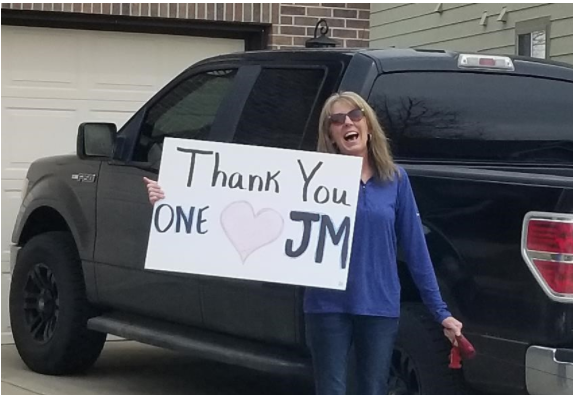

Spreading Joy Through a Physically Distanced Parade

The pandemic has caused worldwide fear, anxiety and stress. Small acts of kindness and joy can help assuage those stressors, combat social isolation and remind us that we are all in this together.

With this in mind, members of JM's Insulation Systems Customer Service team spent a weekend decorating their cars, making posters and spreading joy around their community.

"This idea came about after I dropped off dinner from a local restaurant to a coworker whose spouse is a nurse,” said Jackie Freeman, JM Account Specialist. “I wanted to let her know how much we appreciate their family’s sacrifice for all of us. It was so great to see ‘work family’ in person — while keeping a safe distance.”

Freeman said that after dropping off the meal, she missed her JM family even more and decided to illicit their help to boost morale near the Johns Manville Technical Center in Littleton, Colorado. The group’s route covered over 60 miles and they made 12 stops.

“Our intention was to spread some joy and compassion, and we also received the gift of joy in return,” Freeman said.

JMers’ Families Share Their Stories

We are proud of the contributions JM employees have made amid the pandemic. And we are also proud to share the efforts of our family and friends who work in healthcare or directly contribute to frontline medical workers during this unprecedented health crisis.

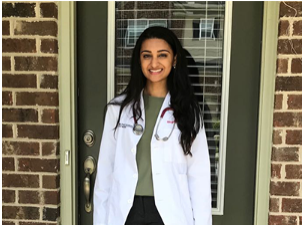

Principle Process Engineer Raman Chiruvella shared the contributions his daughter made as a first-year medical resident at the University of Virginia.

When COVID-19 units were at their highest capacities, young residents like Megha Chiruvella helped by tending to patients who were hospitalized with other conditions while senior doctors and residents cared for patients with COVID-19

“Although we had sleepless nights thinking about our baby, I am proud of her for taking care of people that needed help for 12 to 14 hours every day,” Raman said.

Meanwhile, JMer Lori Roy’s step-daughter, Meagan Miller, donated hand sanitizer by shifting production at the distillery she owns with her husband in Arvada, Colorado.

Talnua Distillery usually focuses its production on authentic Irish whiskey and gin. When the pandemic began, production largely turned to hand sanitizer for first responders, medical facilities and nurses.

The distillery made over 155 gallons of hand sanitizer, put into approximately 2,200 50 milliliter personal bottles and approximately 260 half-gallon jugs. Meagan, her husband, Patrick Miller, and others at the distillery delivered the hand sanitizer to local frontline workers.

“I think this collaboration is a fantastic and concrete way to see exactly how many industries this pandemic has affected and also that industries are being creative in collaborations with each other to get to the other side of this,” Meagan said. “(Making hand sanitizer) is just a tiny way of showing that we're all together in this right now.”