While high-temperature industrial applications require a myriad of design considerations like heat loss, process control, natural resource and carbon reduction, engineers usually agree that personnel protection is the number one concern. Think about it – if a pipe merely appears to be properly insulated and safe to touch, every worker in the area is unknowingly and automatically exposed to a burn risk. This is a risky gamble that could result in people getting seriously injured and could prove to be a very pricey shortcut for the plant owner who will be left to foot the bill for the worker’s comp claim.

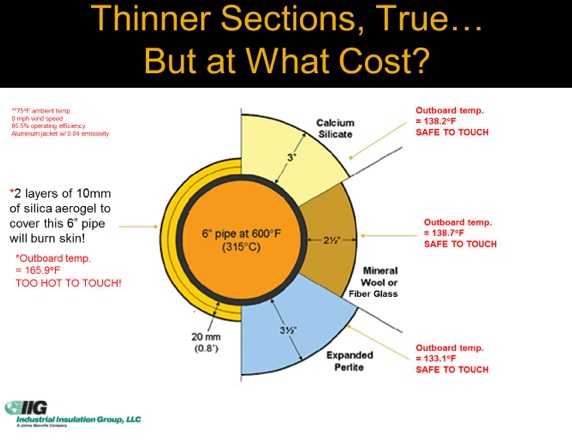

There are a number of pipe-section diagrams that are currently circulating around the market that demonstrate the effectiveness of low k-value insulations; however, many of these diagrams focus entirely on heat loss and fail to account for personnel safety. The diagrams typically show a thinner insulation option that may seem less expensive because it requires less material, but this can be misleading in two ways.

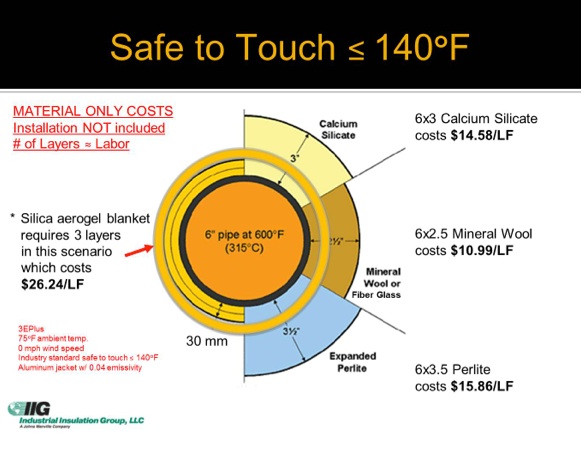

First and foremost, these insulations alone may not be thick enough to safely insulate the pipe or vessel for human contact. The potential accidents that could result from someone touching an inadequately insulated pipe are both costly and avoidable. Secondly, even though these insulations require less material, they are much more expensive than traditional, tried and true insulations such as calcium silicate, expanded perlite, and mineral wool that provide the right balance of process control, personnel protection, CUI protection, and lowest installed cost.

Keep in mind that all insulations that meet the design criteria will do the same job at a given thickness; however, it will always cost more to reduce insulation thickness by using lower k-value blankets or pre-formed pipe coverings. Naturally, the trade-off for these thinner sections is a higher installed cost. Because of this, it is easy to unintentionally create a safety hazard for your employees by focusing only on process control for the sake of saving money.

While the diagrams may imply that thin, lower k-value insulations, such as silica aerogel blankets and needled e-glass pre-formed will provide the same performance as thicker sections of traditional insulations and as such may appear less costly, this is actually misleading. These sections typically need additional layers not shown in the diagrams to achieve safe-to-touch standards.

Industrial Insulation Group (IIG), a Johns Manville Company, understands that process control and personnel safety are not mutually exclusive. We would like to encourage designers to carefully and independently analyze the math and logic behind any diagrams that promote thinner insulation options. If your first priority and standard operating procedures demand 100% personnel protection on all insulated sections, you will always meet or exceed your process efficiency goals.

IIG’s wide breadth of insulation choices, affords us the liberty to work with our customers to help determine the right material or combination of materials that will best meet their project needs and budget goals. Our array of products means we don’t have to take an ideological stand by asserting that one particular formulation is a panacea for every project. We are always happy to share material cost estimates per linear foot of each of the different options in the market. We know that more knowledge = highly informed decisions.