Although spray foam insulation has been on the market for many decades, myths about its properties and use still circulate. Let’s look at a few of the more common myths about spray foam insulation and learn the truth.

MYTH #1: There’s no difference between open-cell and closed-cell spray foams.

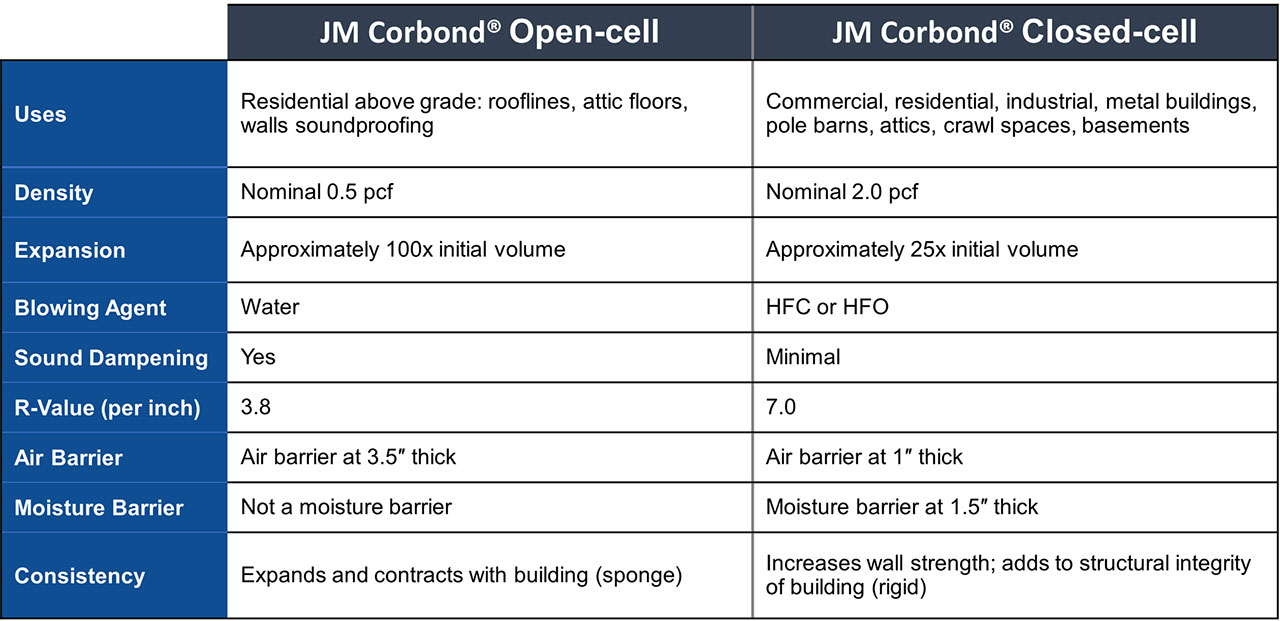

The generic term “spray foam” still appears on many specs, which might suggest that open-cell and closed-cell spray foam are interchangeable. They’re not. At the chemical and microscopic level, the two types of spray foam are vastly different and they each have different strengths and limitations.

Open-cell spray foam is much less dense, expanding more as it is installed. It uses only water as a blowing agent to change it from a liquid to a foam solid. It has comparable thermal and acoustical properties to fiberglass but it’s also an air barrier at a minimum of 3.5 inches of thickness.

Closed-cell spray foam is denser and has a higher R-value. JM Corbond® closed-cell products have an R-value of 7.0 per inch. You need only one inch of closed-cell spray foam for it to be an air barrier and 1.5 inches for it to be a vapor barrier. It uses an HFC or HFO blowing agent to turn it from a liquid to a solid. It’s more rigid and makes the wall stronger. JM Corbond® IV closed-cell spray polyurethane foam (SPF) is a next-generation HFO-blown product that can be produced with a Global Warming Potential (GWP) of less than 2 and with an Ozone Depletion Potential (ODP) of zero.

MYTH #2: Energy performance is entirely dependent on R-value.

Energy performance is actually a very broad term and it depends on many factors. R-value is a measure of how good a single material is at insulating. It’s a product-specific measurement and does not describe the energy performance of the entire wall because walls include components such as sheathing and penetrations that affect energy performance. The measure of the thermal performance of the entire wall assembly is called the U-value and it accounts for framing, sheathing, electrical boxes and all of the other components in a wall beyond the insulation.

Because framing has a lower R-value than insulation, the total U-value will be lower than you might expect based on the R-value of the insulation. A building designed with better air sealing, which can be provided by closed-cell and open-cell spray foam, can use a smaller HVAC system and will decrease energy consumption. Spray foam air seals and can reduce energy consumption when installed as the same R-value as a non-air barrier insulation.

MYTH #3: There’s no impact on performance when installing thick passes versus multiple immediate passes of closed-cell foam.

Many spray foam manufacturers offer high-lift foams that can be installed in one single pass to high thicknesses. These high-lift products are intended to increase installation efficiency. However, there is more risk involved when using one thick pass versus multiple immediate passes. If you install one thick pass, the product may not be dimensionally stable or perform as well as multiple immediate passes. Installing one thick pass, which JM defines as greater than four inches, can compromise the quality of the installed foam. The foam can pull away from the framing, negating both the insulation and the air and vapor barrier benefits. If this occurs, the installer will have to go back and fix these gaps, which reduces installation efficiency significantly.

Check out the JM webinar and white paper for more information on this topic.

MYTH #4: Selecting the right proportioner guarantees on-ratio spray foam.

There are many factors involved in creating on-ratio spray foam. Advances in technology are helpful and have been beneficial to the industry, but it’s important for installers to avoid complacency. The installer must always be aware of environmental and equipment conditions when installing spray foam to ensure that the foam on the wall is the proper ratio. For example, if there is additional moisture on the substrate, the foam on the wall can be off-ratio since the A-side reacts with water. An installer would be able to ascertain that by taking a core sample of the substrate. The bottom line is that there is no substitute for a skilled installer. There is no technology that will guarantee perfect, on-ratio application every single time.

MYTH #5: You’re on your own when applying spray foam.

We sometimes hear from installers that they learned things the hard way because they didn’t get support from their vendor. You are not alone when you’re learning how to install spray foam. TechConnectSM is JM’s technical services team that is available 24x7. TechConnect can come to your site for training, to set up a new rig and to troubleshoot issues and is available for free online, on-call and onsite support to JM customers using JM products.

If you’d like to learn more about the myths surrounding spray foam, check out the webinar, Myths About Spray Foam, or visit the JM website here.