Residential Building Insulation

Johns Manville’s residential insulation products help maintain energy efficiency and lower heating and cooling costs, making homes more comfortable year round. Johns Manville is committed to providing the high quality products, resources, guidance and on demand support you need on the job.

Residential Products

Fiberglass

Johns Manville Formaldehyde-free™ fiberglass insulation provides thermal and acoustical control for both vertical and horizontal applications. Fiberglass insulation is available in a wide range of thermal resistance R-values and is available unfaced or with a variety of facings, including kraft or foil.

-

Attic Protector Blow-In

Perfect for hard-to-reach areas within attics, like corners, edges and around framing, Johns Manville Attic Protector is premium blown-in fiberglass insulation. -

Cavity-SHIELD Fiberglass

Formaldehyde-Free™ fiberglass batts made of long, resilient glass fibers bonded with a thermosetting resin. -

Climate Pro Blow-In

Handling hard-to-reach cavities and corners with more consistent coverage makes installation faster and easier. -

ComfortTherm

Plastic-wrapped batts and rolls providing a dust- and itch-free installation.

-

FSK-25 Batts

Combining fire resistance with a vapor barrier, Johns Manville FSK-25 batts are designed with a foil facer that can be left exposed where codes permit.

-

Kraft-faced Fiberglass

For thermal and acoustical performance that lasts, Kraft-faced fiberglass insulation is paper-faced to help control moisture in concealed applications. -

Panel Deck FSK-25

Batts laminated with a foil facing for excellent fire resistance and a vapor barrier. -

Spider Plus Blow-In

Uses interlocking fiber technology to fill all gaps and voids quickly with no adhesive or netting. -

Unfaced Fiberglass

Unfaced batts and rolls provide heat control from the exterior while effectively controlling noise in interior walls.

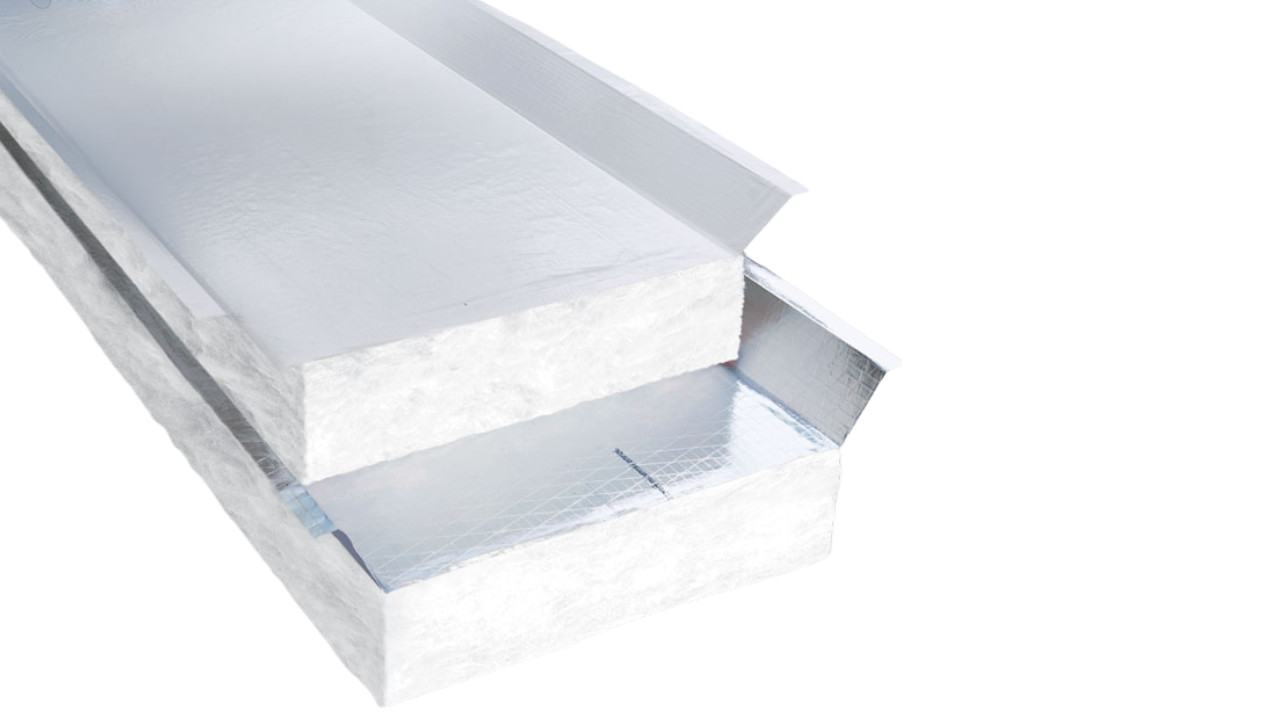

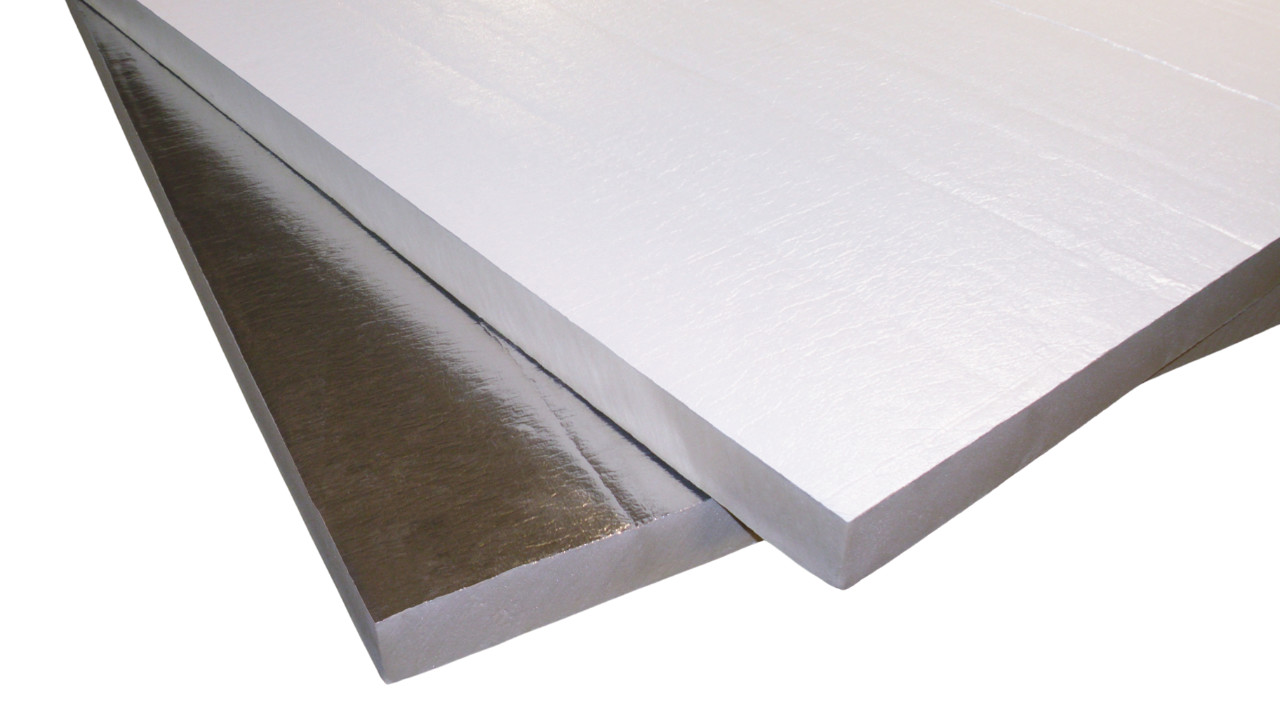

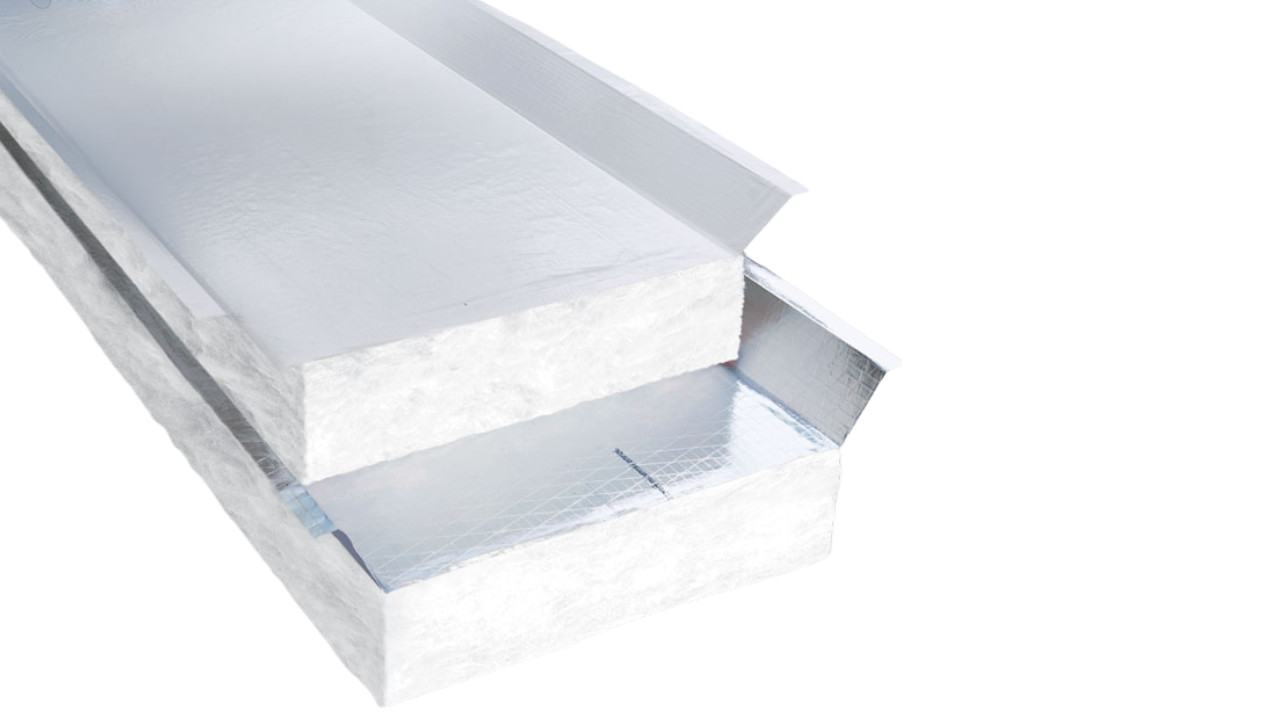

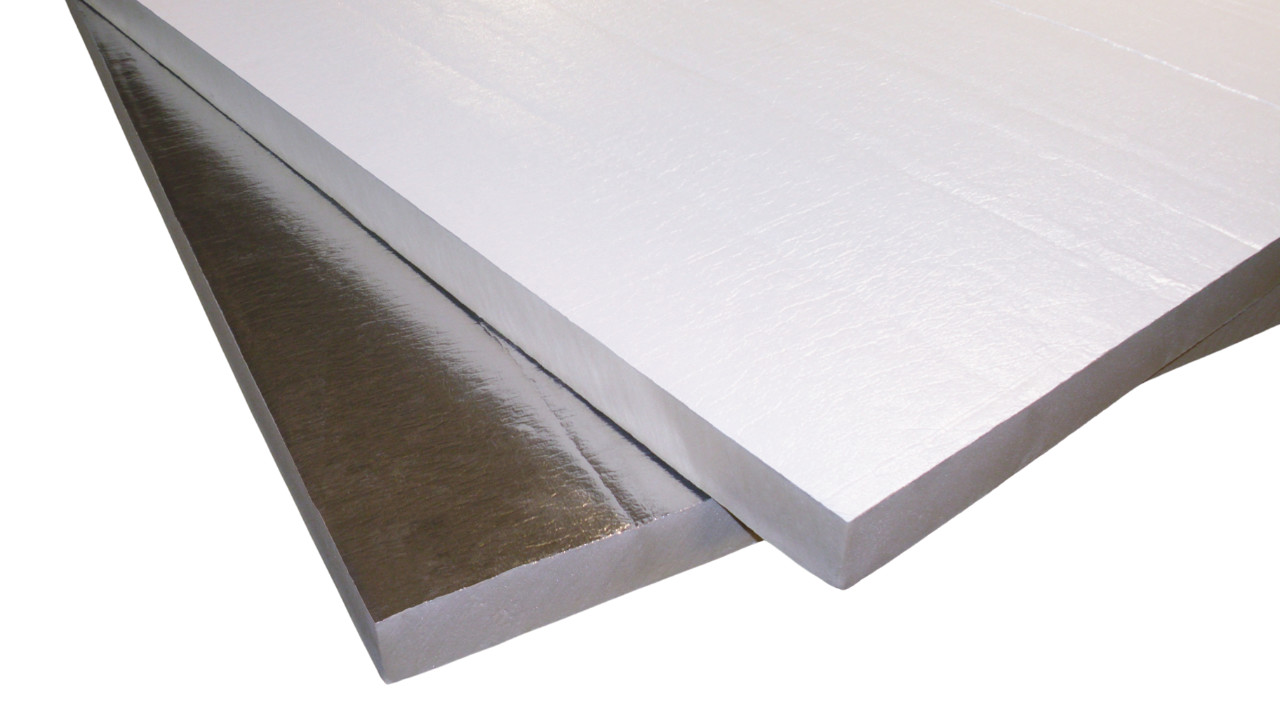

Foam Board / Continuous Insulation

Johns Manville Polyiso foam continuous insulation boards provide a layer of insulation to reduce thermal bridging and improve energy efficiency. Polyiso consists of a uniform closed-cell polyisocyanurate foam core and provides one of the highest R-values per inch of any rigid insulation.

-

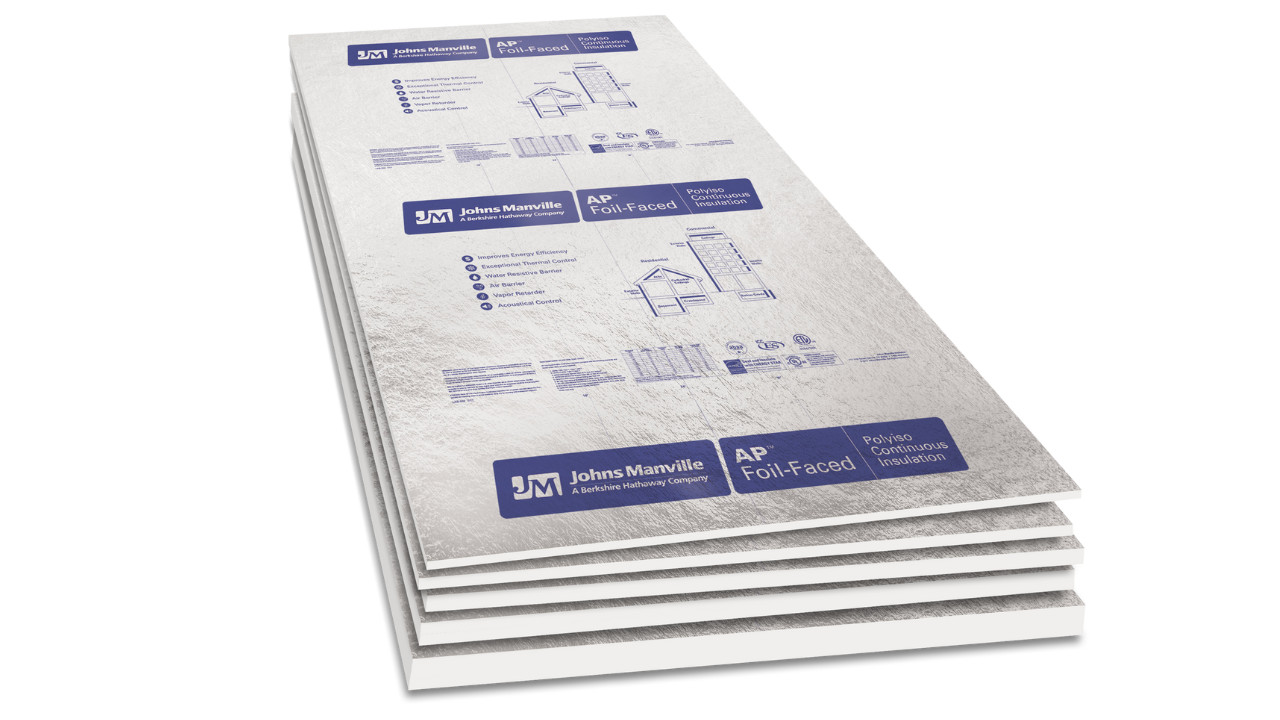

AP Foil-Faced Foam Continuous Insulation

Provides exceptional heat, moisture and air control and, when installed correctly, eliminates all major thermal bridges that cause heat loss. -

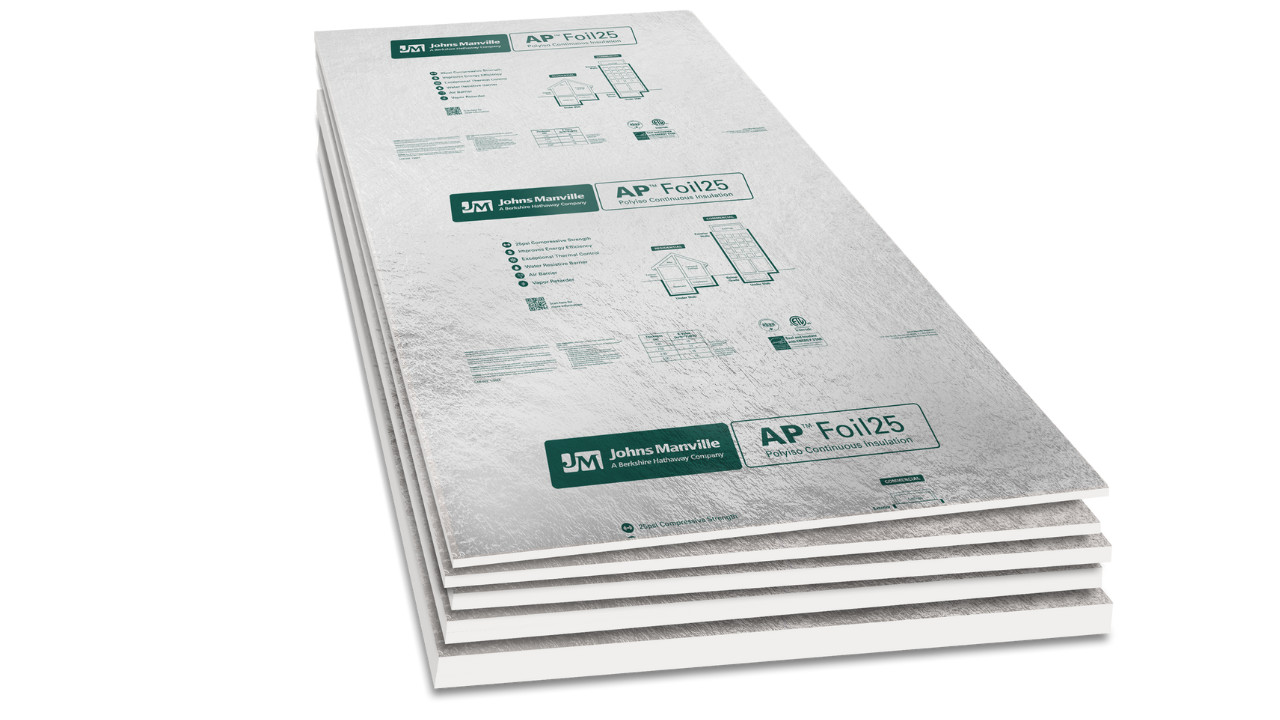

AP Foil25 Polyiso Continuous Insulation

Well suited for below-grade residential and commercial applications where higher compressive strength boards are preferred for certain exterior cladding systems. -

CI Max Polyiso Foam Continuous Insulation

Designed for easy installation in exposed interiors, ideal for places where high efficiency is required. -

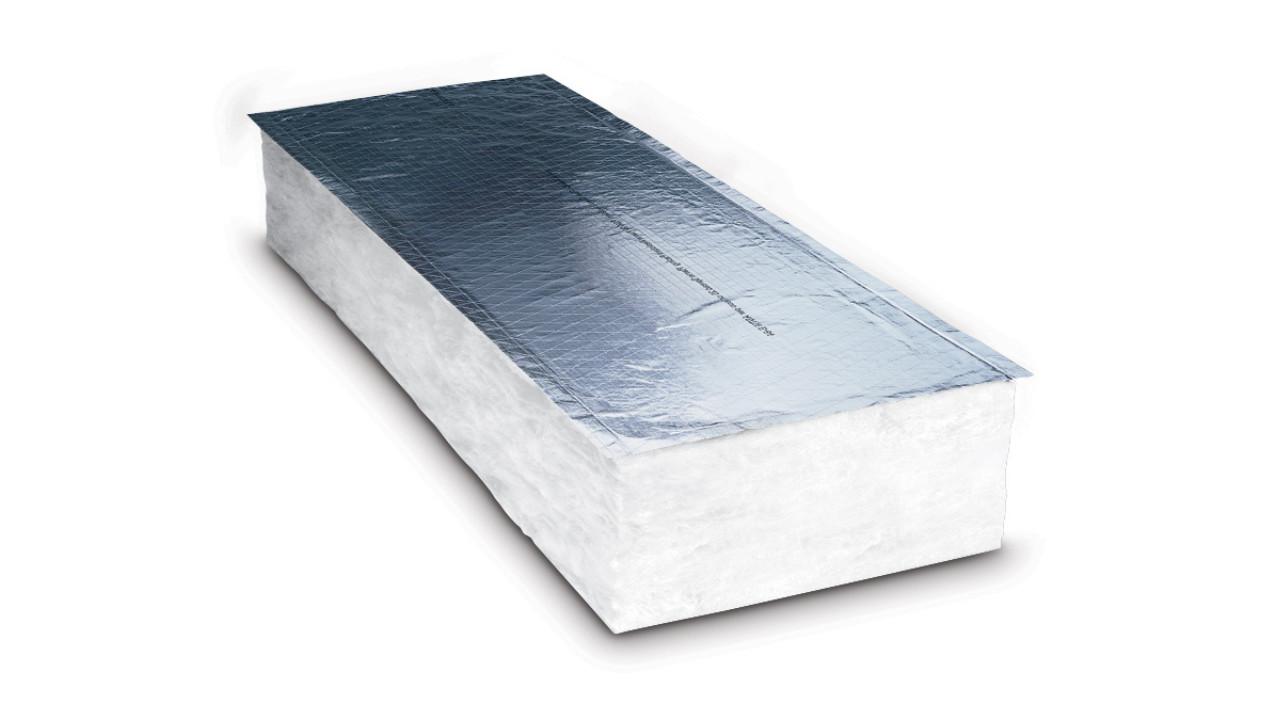

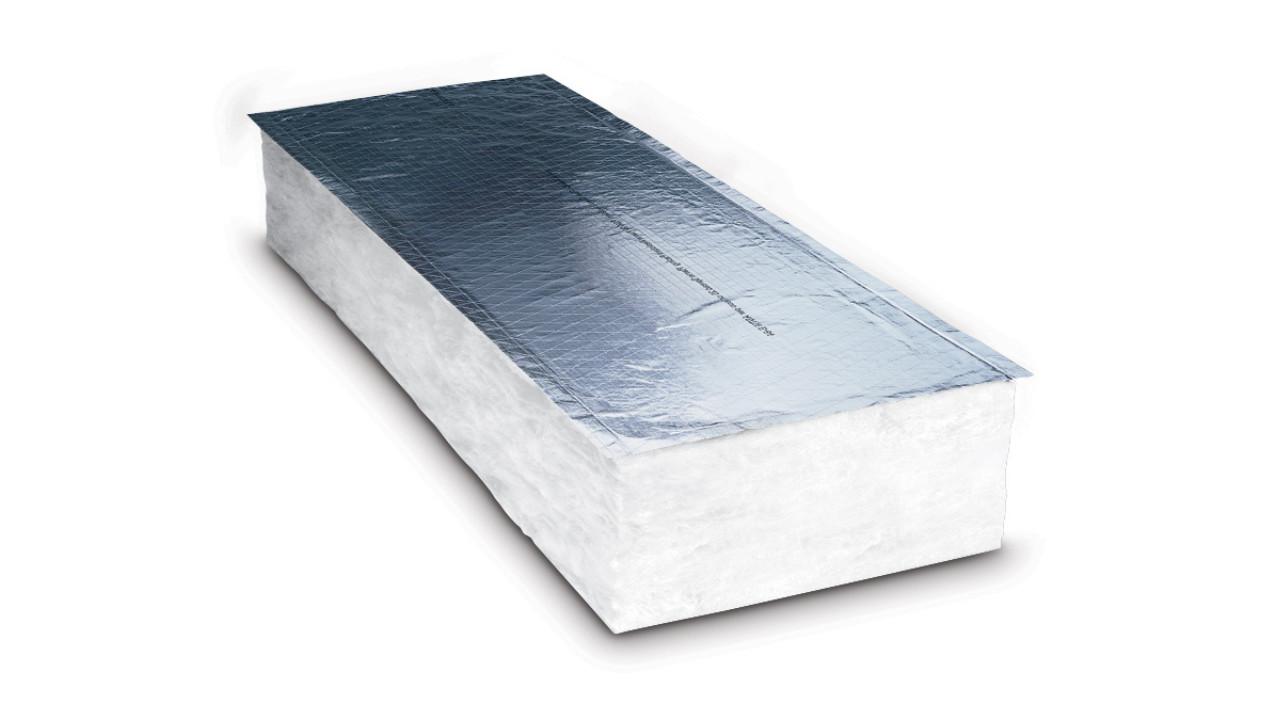

R-Panel Roof Insulation

Rigid roof insulation board with high thermal efficiency.

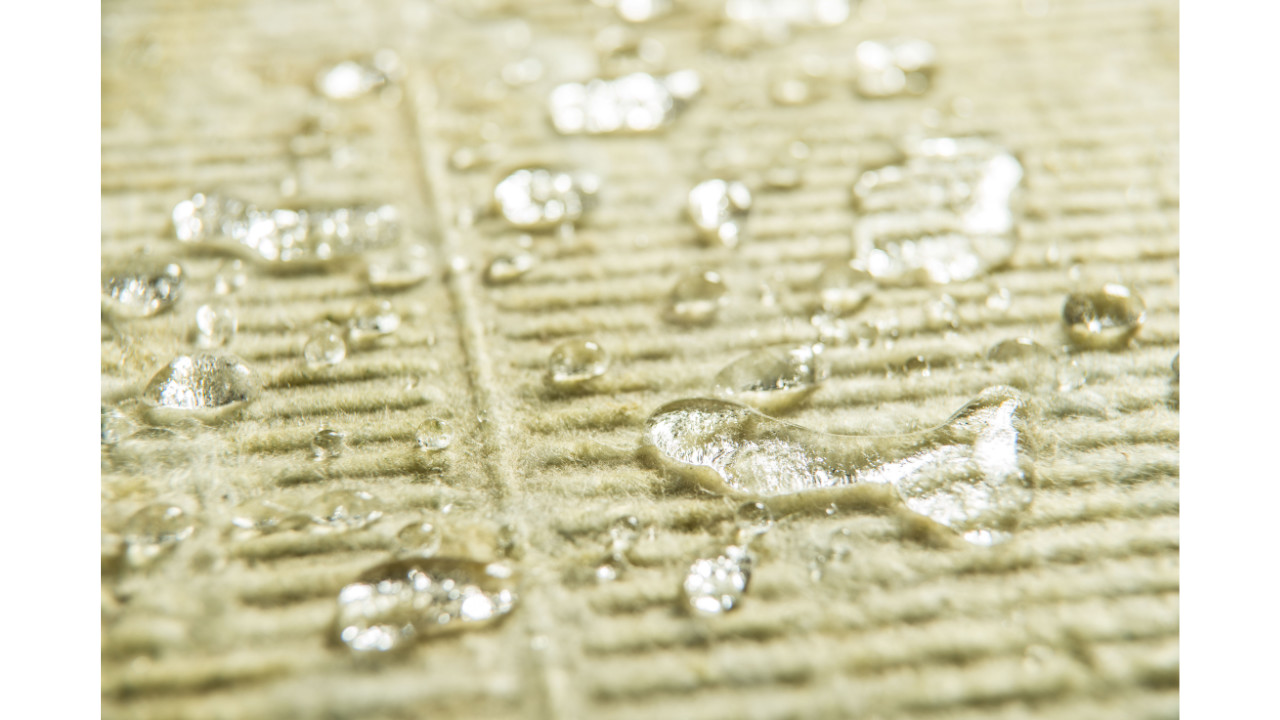

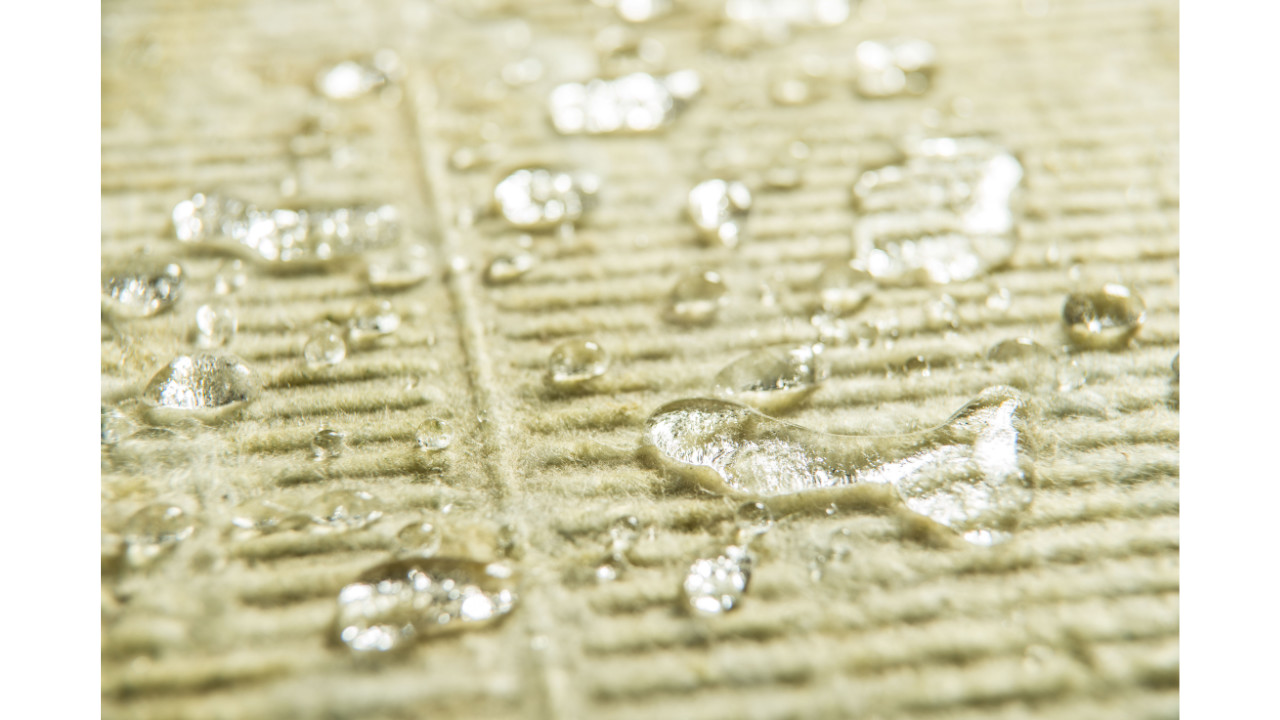

Mineral Wool

Johns Manville Mineral Wool batts are made of inorganic fibers derived from basalt, a volcanic rock. Our advanced manufacturing technology ensures consistent product quality, with high-fiber density and low shot content for excellent performance.

-

CladStone Water and Fire Block

Inorganic, noncombustible, moisture repellent and will not mildew or support corrosion. -

Sound and Fire Block Mineral Wool

Helps delay the spread of fire between interior floors and rooms. -

TempControl Mineral Wool

Designed to help delay the spread of fire. Offers thermal control for wood-stud cavities of exterior walls, basements and heated crawlspaces.

Spray Foam

John Manville's complete line of spray polyurethane foam (SPF) insulation solutions provides superior thermal energy efficiency, as well as advanced air and sound control. SPF insulation completely covers gaps and voids, works in hard-to-insulate areas and can exceed the performance of traditional fiberglass insulation. Both Johns Manville SPF product categories, open-cell and closed cell, deliver high yield, superior performance and exceptional sprayability.

-

JM IV HFO

Next generation HFO blown, two-component, medium-density, Class 1 rated, SPF insulation system. Designed to insulate commercial, residential and industrial buildings.

-

JM No Mix Open Cell (NMOC)

Designed for insulating the interiors of commercial, residential and industrial buildings, and does not require mixing. -

No-Burn Plus ThB

Tintable white, thin film intumescent coating can be applied over JM open and closed cell spray polyurethane foams.

Fiberglass

-

Attic Protector Blow-In

Perfect for hard-to-reach areas within attics, like corners, edges and around framing, Johns Manville Attic Protector is premium blown-in fiberglass insulation. -

Cavity-SHIELD Fiberglass

Formaldehyde-Free™ fiberglass batts made of long, resilient glass fibers bonded with a thermosetting resin. -

Climate Pro Blow-In

Handling hard-to-reach cavities and corners with more consistent coverage makes installation faster and easier. -

ComfortTherm

Plastic-wrapped batts and rolls providing a dust- and itch-free installation.

-

FSK-25 Batts

Combining fire resistance with a vapor barrier, Johns Manville FSK-25 batts are designed with a foil facer that can be left exposed where codes permit.

-

Kraft-faced Fiberglass

For thermal and acoustical performance that lasts, Kraft-faced fiberglass insulation is paper-faced to help control moisture in concealed applications. -

Panel Deck FSK-25

Batts laminated with a foil facing for excellent fire resistance and a vapor barrier. -

Spider Plus Blow-In

Uses interlocking fiber technology to fill all gaps and voids quickly with no adhesive or netting. -

Unfaced Fiberglass

Unfaced batts and rolls provide heat control from the exterior while effectively controlling noise in interior walls.

Foam Board / Continuous Insulation

-

AP Foil-Faced Foam Continuous Insulation

Provides exceptional heat, moisture and air control and, when installed correctly, eliminates all major thermal bridges that cause heat loss. -

AP Foil25 Polyiso Continuous Insulation

Well suited for below-grade residential and commercial applications where higher compressive strength boards are preferred for certain exterior cladding systems. -

CI Max Polyiso Foam Continuous Insulation

Designed for easy installation in exposed interiors, ideal for places where high efficiency is required. -

R-Panel Roof Insulation

Rigid roof insulation board with high thermal efficiency.

Mineral Wool

-

CladStone Water and Fire Block

Inorganic, noncombustible, moisture repellent and will not mildew or support corrosion. -

Sound and Fire Block Mineral Wool

Helps delay the spread of fire between interior floors and rooms. -

TempControl Mineral Wool

Designed to help delay the spread of fire. Offers thermal control for wood-stud cavities of exterior walls, basements and heated crawlspaces.

Spray Foam

-

JM IV HFO

Next generation HFO blown, two-component, medium-density, Class 1 rated, SPF insulation system. Designed to insulate commercial, residential and industrial buildings.

-

JM No Mix Open Cell (NMOC)

Designed for insulating the interiors of commercial, residential and industrial buildings, and does not require mixing. -

No-Burn Plus ThB

Tintable white, thin film intumescent coating can be applied over JM open and closed cell spray polyurethane foams.