Spray foam insulation is known for offering excellent thermal control for residential and commercial applications. It can be used in wall cavities, attics, and even as a continuous exterior insulation solution. There are two different types of spray foam, open cell, like JM Corbond® Open-cell, and closed cell, like JM Corbond® III, and each offers varying benefits concerning cost and performance. Understanding the differences between open and closed cell spray foam insulation can be critical to ensuring your home’s walls and attic are properly sealed and insulated.

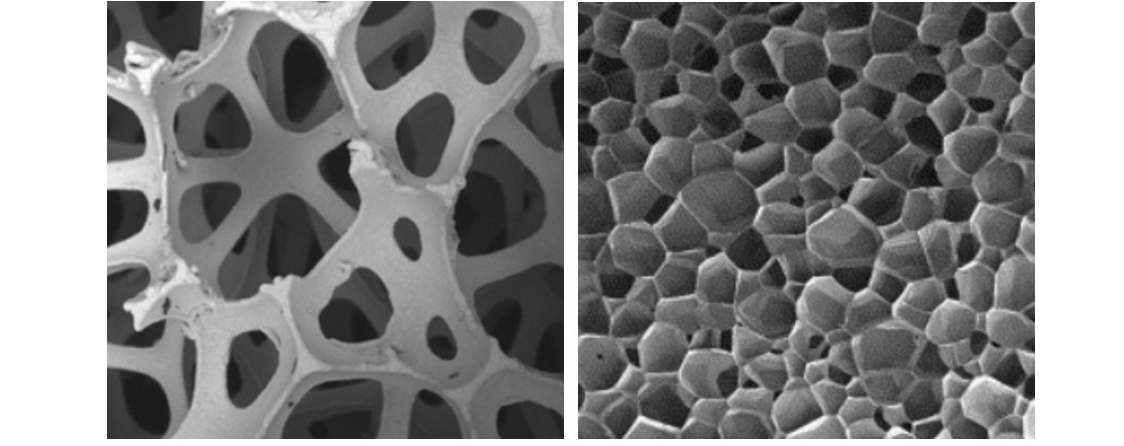

Open cell spray foam and closed cell spray foam have different physical structures that give them different thermal and acoustic performance properties. When considering these differences, understanding how foam insulations are formed is important. Foam insulations are made from two chemicals that expand rapidly after they come into contact with each other. During the expansion, bubbles are formed. In open cell spray foam, the bubbles rupture, leaving behind only the struts (the point at which two bubbles were touching each other), as shown in the picture on the left. In closed cell insulation, the bubbles don’t rupture, creating interconnected closed pockets, shown in the picture on the right.

This microscopic difference in the two products creates a dramatic difference in performance. Closed cell spray foam has an R-value of R-7 per inch. In comparison, open cell spray foam has an R-value of R-3.8 per inch. Additionally, the materials have decidedly different densities. Open cell spray foam has a density of 0.5lb/ft3 whereas the density of closed cell spray foam is 2lbs/ft3. While both materials can be used as an air barrier (open cell at 3.75” thickness or greater and closed cell at 1” thickness or greater), only closed cell spray foam creates a fully sealed system that can be used as an air and vapor barrier (at 1.5” thickness or greater). That being said, the porous structure of open cell spray foam allows for improved acoustics over closed cell spray foam.

While open cell spray foam tends to be less costly than closed cell foam in terms of material costs, the difference in the R-values between the two products means that any system using open cell spray foam will need more material than closed cell spray foam to achieve a given R-value. This is important to keep in mind as initial material costs may not be representative of the overall installed cost of the project.

Though you can use either open or closed cell spray foam insulation anywhere, many people like to use the southern Pennsylvania border as a rule of thumb: in structures south of the southern border of Pennsylvania, use open cell, north of that border use closed cell. The reason for this is that the temperature deltas from the outdoor ambient temperature to indoor temperatures tend to be significantly smaller for structures located in the south than those located north.

For example, in the southern states with milder winters and hotter summers, the difference in the outdoor temperature and indoor temperature is approximately 30°F to 40°F, even at the height of summer and the middle of winter. In contrast, in the northern climates, such as North Dakota, where average winters have 50 days of below 0°F temperatures, the temperature delta between outdoors and indoors is often 70°F or more. This means that structures in North Dakota will need substantially more robust insulation to combat that temperature delta and maintain thermal efficiencies than structures in southern, more temperate climates. Keep in mind that while open cell spray foam can be used anywhere, it does not create a vapor barrier like closed cell spray foam does. Thus, any structure using open cell spray foam (whether it is in the north or the south), would need an additional vapor barrier to prevent condensation from forming.

While both open and closed cell spray foam will entirely fill the cavities where they are installed (when installed properly), only closed cell spray foam can offer the added benefit of a vapor barrier. If the application calls for an integrated vapor barrier and insulation all in one, closed cell spray foam insulation will provide this necessary performance. For this reason, all continuous exterior insulation applications using spray foam should be closed cell.

Both materials offer unique benefits that system designers and installers can rely on to design and install robust, thermally-efficient structures. To learn more about spray foam insulation visit our spray foam insulation page, or whysprayfoam.org.