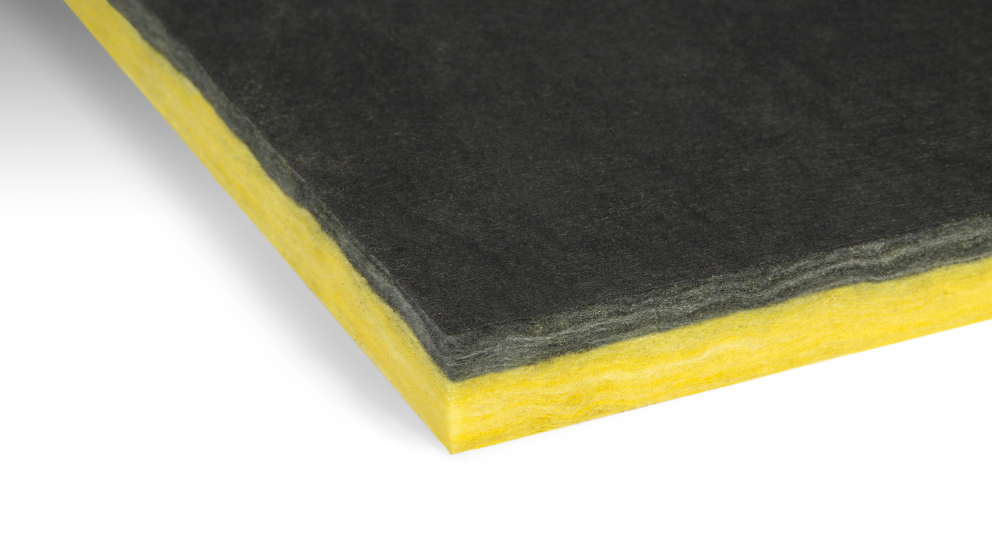

Airstream surface coatings, like Johns Manville’s Permacote®, are not what most would consider “new technology.” At JM, we offer both coated and uncoated duct insulations for a variety of applications, and we know that HVAC insulation system designers often have to weigh the benefits of selecting a coated insulation over an insulation with a standard glass-mat airstream facing or even using no facing at all.

This frequently means balancing the cost against the benefits, and with coatings like Permacote, there are four primary benefits that system designers should be aware of before making a choice.

- Helps protect insulation surface from mold intrusion:

Anyone who works in the building industry knows that mold and mildew are bad news. Not only do they create inherent health risks for the building occupants, but once mold is present, it can often be difficult to remove. When it comes to remediating mold growth within insulated ducts, any affected insulation is typically removed and replaced with new material – very rarely is the insulation salvageable. This is why Permacote is so useful. Permacote coating contains an EPA-registered antimicrobial that is designed to protect the airstream surface and the fiberglass insulation from mold or mildew growth. While the fiberglass itself does not serve as a food source for microbial growth, mold can grow on almost any surface if dirt or other contaminants are present as a food source. Permacote can help prevent mold from penetrating into the fiberglass substrate and damaging the insulation irreparably.

- Helps prevent any loose fibers from entering the airstream

In addition to protecting the insulation, Permacote acts as an extra barrier to hold and encapsulate the underlying insulation. While our insulations (coated and uncoated) undergo rigorous UL Air Erosion testing to ensure that the materials do not show signs of delamination, erosion, or flaking when in use, the presence of the Permacote coating can add extra protection and durability to the airstream surface of the insulation.

- Improves water-resistance

When handling fiberglass insulation, all efforts should be made to keep the material dry during transportation, storage, installation, and use. That said, occasionally small drops of water may land on the airstream surface when in use – either as a result of a leak or condensation. Permacote can help add a layer of protection between the water and the fiberglass substrate that can prevent small amounts of water from seeping into the material. Bear in mind, it does not make the insulation waterproof, but for small amounts of water, it can be sufficient to hold the water on the surface until it evaporates, preventing water infiltration into the fiberglass substrate. The water repellency of Permacote is tested using INDA 80.6, an evaluation of water resistance in nonwoven fabrics. With a result of > 6, JM’s insulations with Permacote coating offer measurably improved water repellency over uncoated insulations and even some competing coated insulations. If you choose to specify a coating to improve your insulation system’s water repellency, make sure to call out Permacote coating in the specification to get the desired performance.

- Improves handleability during fabrication and installation

One of the other benefits we see from a coated airstream surface is that it improves the material’s handleability during fabrication and installation – especially during cutting. Occasionally, uncoated fiberglass can snag and pull when it is being cut, similar to cutting a t-shirt. The coated airstream surface creates a uniform surface that can be cut cleanly and rapidly. This surface doesn’t typically snag or catch on the sharp edge as the insulation is cut during fabrication.

Johns Manville offers a variety of insulations with the Permacote antimicrobial coating that can be used in a range of applications from spiral to rectangular ducts:

- Linacoustic® RC Duct Liner

- Linacoustic® RC HP

- Linacoustic® R-300 Duct Liner Board

- Spiracoustic Plus® Spiral Duct Liner

- SuperDuct® RC Duct Board

If you would like more information about Permacote, please contact us.