In the relentless pursuit of excellence at Johns Manville, the bedrock of our success lies in ensuring the safety and well-being of our most valuable asset – our employees. As we reflect upon our safety journey and plan for the year ahead, it is imperative to underscore the fundamental importance of safety.

A thorough safety program not only prioritizes the well-being of our employees, but also brings substantial advantages to our customers. Comprehensive safety measures and trainings lead to a workplace environment with reduced loss time due to accidents or injuries ensuring the best-qualified workers are in place. This contributes to the overall efficiency of the production process, production of the highest quality product, and timely deliveries, fostering a consistent and trustworthy experience for our customers.

JM’s Proactive Approach and Record Achievements

The past year has been marked by significant achievements and a steadfast commitment to fostering a safe and secure working environment at JM. One of the key leading indicators of our safety performance is the completion of an Annual Health and Safety Action Plan, a proactive initiative aimed at reducing risks across all our facilities. In 2023, all Engineered Products plants completed their action plans at an impressive rate exceeding 90%. The completion of the Annual Health and Safety Action Plans is a standout achievement as it is a purely proactive approach taken by each plant. We also measure completion of specific preventive and corrective actions to ensure we are following through on our safety commitments. For 2023, 97% of actions were

completed on time.

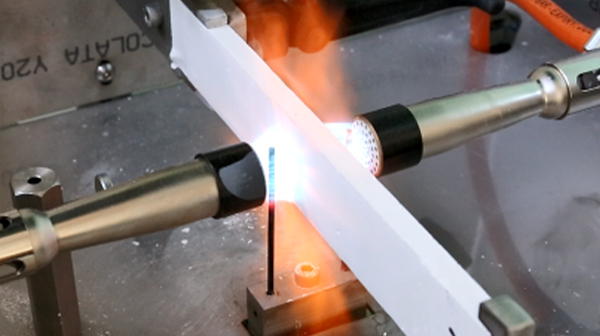

"One of our highlighting achievements from 2023 is the successful completion of a furnace rebuild in Waterville, Ohio that was accomplished safely with zero accidents. This is a noteworthy accomplishment given the degree of risk associated with this type of work.”

Ted Rogers, Global H&S Lead,

Johns Manville Engineered Products

Strategic Investments Transform Workplace Safety in JM Facilities

Investments in safety equipment, training, and technology have played a pivotal role in enhancing workplace safety. In our Spartanburg, South Carolina facility, we highlighted a project aimed at reducing collisions between pedestrians and mobile equipment, such as forklifts, which involved a physical change to the work environment through specific traffic patterns and physical barriers. In our Waterville, Ohio plant, new work platforms were provided to prevent falls from elevation during maintenance work. Our Etowah, Tennessee plant invested in a new direct-reading, data-logging formaldehyde detector to verify the effectiveness of engineering controls in minimizing exposure. Safety improvement investments have also been made for loss of mat line edge trim, which ensures better control of this upset condition, reducing the risk of injury.

In Europe, significant strides have been made, including the automation of the winding room in Trnava, Slovakia, reducing ergonomic injuries, and the implementation of an electronic permitting process. This process enhances user-friendliness, practicality, and effectiveness in overseeing contractor work, contributing to successful pre-startup safety reviews, and ensuring completeness and accuracy in permits for work at heights, entry into confined spaces, and hot work.

5 Tips on How to Make Safety a Priority

Building on Success: JM’s Safety Triumphs and Forward-Looking Plans for 2024

The safety strategy for 2024 is not changing much. Our focus will be on the JM Safety Process with continued emphasis on JM Life Critical Activities and identifying and correcting risks that can cause serious injuries or fatalities (SIF). The three elements of the JM Safety Process are Prevent, Learn and Fail Safe. This collective effort underscores our belief that creating a safer workplace is the most sustainable approach to reducing work-related injuries. As we reflect on the achievements and investments of the past year, we look forward to the continued pursuit of excellence in safety at Johns Manville.

-

Engineered Products

-

Engineered Products