According to the U.S. Occupational Health and Safety website, Artificial Intelligence (AI) is one of the key ways companies can help leverage new technologies with safety improvements, particularly for employees who work on their feet all day. AI-driven algorithms help pinpoint ergonomic risks and reduce overexertion, the leading cause of injury for all age groups according to the National Safety Council. Johns Manville is proud to have launched a new AI concept at our locations to help prevent injuries and make work more comfortable for our employees.

The JM Environmental, Health and Safety (EHS) team has rolled out its new AI-driven ergonomics program at 26 JM plants, thus far.

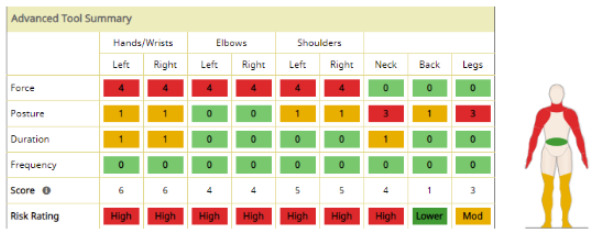

The new motion capture tool provided by Humantech, a leading ergonomics services provider, enables a safety professional to record a video of any physical task. The system analyzes the level of ergonomic risk by assessing factors including force, strain on posture, duration and frequency. EHS professionals at JM used to complete a similar process manually, which required roughly 45 minutes of analysis for each recorded task. Humantech’s technology reduces that time to just 10 minutes.

A JM safety specialist can use the matrix below to find the most effective way to address ergonomic hazards and prioritize corrective actions for high-risk tasks. This new assessment not only speeds up the process for identifying and correcting potential safety hazards, it also enables JM employees to capture new risks they may have missed completely prior to using the AI tool.

Since the new program began, 189 ergonomic improvements have been implemented, and the JM facilities that use the technology have reduced their risk of injury by 30%.