As building designers seek to create buildings made of materials that are healthier for the environment and the buildings’ inhabitants, certifications like Underwriters Laboratories’ (UL) GREENGUARD can help them identify materials that have low chemical emissions. UL’s GREENGUARD Certification program is recognized and referenced in numerous building programs, standards, and specifications around the world. Products with GREENGUARD certifications can contribute to points-based green building rating systems, such as LEED, BREEAM, Fitwel, and others. Additionally, they satisfy code or ordinance criteria and meet architectural specifications for indoor air quality.

There are three tiers of GREENGUARD certification: GREENGUARD Certified, GREENGUARD Gold, and, GREENGUARD Formaldehyde-Free. Each certification has specific maximum requirements for both emissions of volatile organic compounds (VOCs) and modeled indoor concentrations, or, in the case of the Formaldehyde-Free Certification, requirements for maximum formaldehyde emissions and modeled concentrations. VOCs include a variety of different chemicals, some of which have short-term or long-term health effects on humans.

In order to be certified, the product must meet specific requirements set forth by UL:

- GREENGUARD Certification: Total VOC emission rate of 500 μg/m3

- GREENGUARD Gold Certification: Total VOC emission rate of 220 μg/m3

- GREENGUARD Formaldehyde-Free Certification: Must meet GREENGUARD Gold requirements and have a formaldehyde emission factor of less than or equal to 5 µg/m2•hr at 24 elapsed exposure hours or 3 µg/m2•hr at 336 elapsed exposure hours.

The GREENGUARD Formaldehyde-free certification is the most stringent of the three certifications, and GREENGUARD Gold status is especially relevant in school and health care applications.

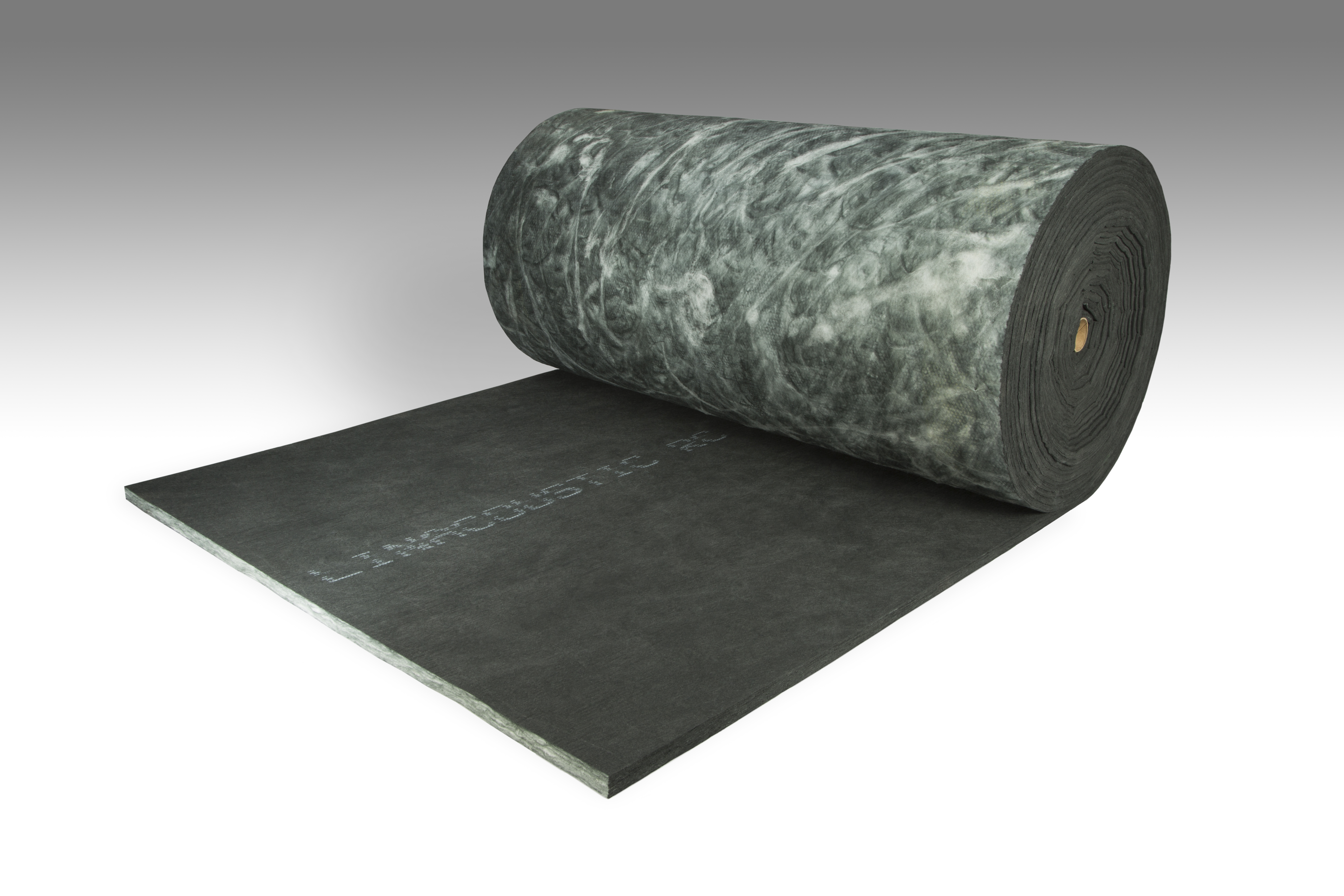

Many products that go into homes and buildings, from furniture, to decorations, to building materials, receive GREENGUARD certifications to allow consumers to identify them as low-emitting products. At Johns Manville, many of our insulation materials are GREENGUARD or GREENGUARD Gold certified – and we recently had our HTB 26 Spin-Glas® fiberglass blanket and our Linacoustic® RC & Linacoustic® RC-HP fiberglass ductliner GREENGUARD Gold certified.

HTB 26 Spin-Glas is unique because the binder used to make the material is Formaldehyde-Free™. This is what gives the blanket its white color. HTB 26 Spin-Glas is often considered a specialty product and is used frequently as the insulation in insulating pads and blankets. HTB 26 Spin-Glas is also often used in OEM applications to control contain heat buildup. Since HTB 26 Spin-Glas is a light density, flexible product, it is also frequently used in marine applications, and it is best used where it will be supported by a component of the application as it lacks the structure to support itself.

Linacoustic RC and RC-HP are industry-leading duct liners, and with the GREENGUARD Gold certification, they are now ideal for applications in schools or hospitals, where low-emitting materials are a requirement.

Other GREENGUARD Gold, Formaldehyde-Free™ products we offer are our Zeston® PVC Inserts, pre-cut inserts used to insulate fittings below PVC jacketing and our entire Microlite® Duct Wrap portfolio (FSK, Black PSK, and White PSK).

That being said, a product does not have to be Formaldehyde-Free™ to be low-emitting and receive a GREENGUARD Gold Certification. For example, our fiberglass pipe insulations, Micro-Lok® HP and Micro-Lok® HP Ultra both have a GREENGUARD Gold certification. These jacketed pipe insulations are ideal for indoor, mechanical applications.

As system designers strive to build smarter, greener, and healthier buildings, certified materials will be integral components to achieving this goal. More information about each of these products can be found on our product data sheets and our product safety data sheets.

NOTE: Greenguard tests all manufacturers’ fibrous insulations at 74oF per CDPH SM v1.2. At high temperatures (>450oF) all binders, including formaldehyde-free binders, may thermally degrade and low chemical emissions may not be achievable.