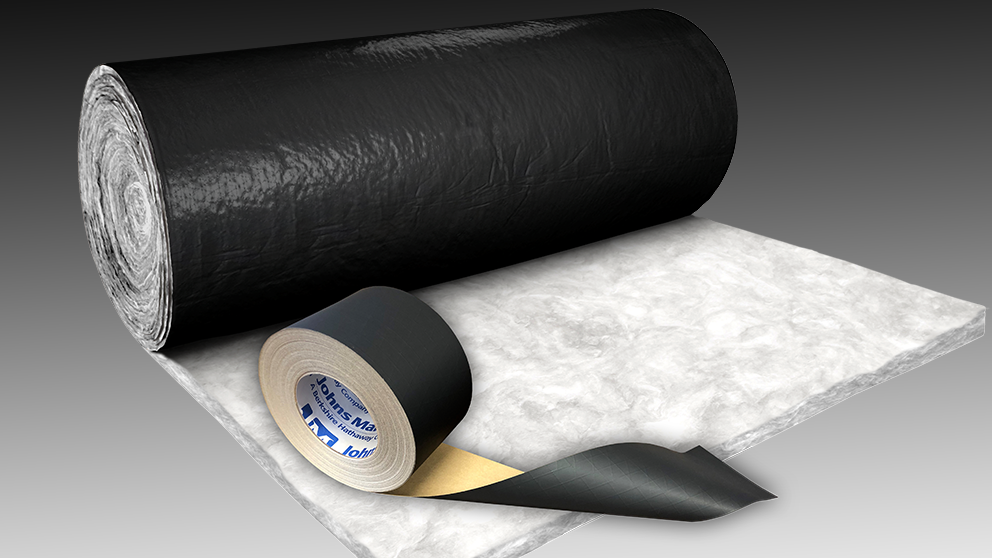

Last June, we introduced a black-coated Polypropylene-Scrim-Kraft (PSK) duct wrap insulation, Microlite® Black PSK Duct Wrap. Like our other Microlite Duct Wrap Insulations, our Black Duct Wrap is Formaldehyde-free™ and has a vapor-retarder facing with a perm rating of 0.02 perms. However, unlike traditional duct wrap insulation, our black ductwrap is designed to be left exposed specifically for aesthetic applications.

One of the first facilities to install our new Microlite Black PSK duct wrap was the Colorado State University urgent care clinic. Miller Insulation, an

employee-owned company that has been in business for nearly 50 years, was contracted to insulate the HVAC system at the urgent care clinic. Miller

specializes in commercial, oil field, and industrial insulation and they have operations in 36 states.

We conducted an interview with Miller Insulation Project Manager and Estimator, Mack Peterson to take a closer look at his experience using Microlite Black PSK. Peterson has been in the business for 30+ years and has been a project manager and estimator for the past 20.

Q: Why did Miller choose to use black duct wrap for the CSU project?

A: CSU was going for a more industrial, aesthetic look with exposed ceilings. The look they went for was a round-tube railing system that will outline the walls rather than look like a ceiling grid. This was our first time using black duct wrap, but its clean look and thermal performance made it a great fit.

Q: Can you walk us through an introduction to this job and some of its unique requirements?

A: This urgent care facility was originally built in 2017, and there are four floors and a basement. My team was responsible for installing and insulating

the HVAC systems on the first three floors and the basement. The fourth floor was left unfinished until an occupant could be found for the space. This allows them to build out the space in the way that will suit the needs of the occupant. The black duct wrap was used in the common rooms of the urgent care and on the outside of the exam rooms.

Q: What materials did they use to insulate the HVAC system?

A: The entire floor was insulated with duct wrap. For the exposed ducts, we used Microlite Black PSK, and for the unexposed ducts, we used Microlite FSK.

Q: As a contractor working with the material, what are some pros and cons you had with Black Duct Wrap?

Pros: Overall, the Black Duct wrap is very easy to install. None of my guys ran into any major issues with the product that were not easily overcome. The product installs similarly to the FSK duct wrap, and the color gives it a nice, clean finish. It is definitely a difference maker in terms of appearance.

Cons: We found there were two things we needed to be aware of when installing Microlite Black PSK duct wrap. First, when you staple it, the staples penetrate the black facing. This causes the white insulation to show through, and you’d have little white specs where the staples were. We fixed that issue by ensuring the seam where the staples were, was always placed on top of the duct. Second, keeping it clean proved to be a bit

of a challenge. Instead of laying it on the ground where the black coating could get scraped off or pick up dirt, we simply broke down the pipe boxes and laid them on the floor along with plastic wrap to help keep the duct wrap clean.

Q: Do you have any best practices you would recommend to other contractors installing the material to ensure a clean finish?

A: For one, always use a sharp knife to get the cleanest cuts, but most installers know that goes without saying. When you’re installing an insulation that is part of the design, however, clean cuts are very important. For this job specifically we used very large hangers. It took some creativity, but we were able to use the tape and the wrap to cover and conceal the hangers so the black wrap looked consistent from start to finish. Like I said, make sure you lay down boxes or plastic before laying the wrap on the ground so it stays clean and the finish doesn’t get scraped off, and place the seams on top of the duct. Other than that, the wrap itself has a high-quality clean finish, especially with ducts that do not require large hangers.

Q: Are there any other details about the project that you would like to share?

A: When the general contractor, US Engineering, approached us about using Microlite Black PSK, we were pretty excited because we were one of the first ones to install it. Using an insulation as part of the design is an interesting concept. It’s great to be able to say that we were one of the first teams to install this new product.

If you would like more information about Johns Manville’s Microlite Black Duct Wrap, you can visit the product page on our website, or watch this recorded webinar on insulations for aesthetic applications. For more information on Miller insulations, visit millerinsulation.com.