Thermal shift is a relatively new concept in the industrial insulation industry. In 2015, researchers were testing the thermal performance of several different insulations, and discovered that, after several hours of exposure to temperatures at or above 300°F, silica aerogel has a decrease in thermal performance. This decrease in performance is called thermal shift. Fortunately, the other insulation materials that were tested proved to be impervious to thermal shift; however, it is important to take a closer at what happens to silica aerogel that causes its decline in thermal performance.

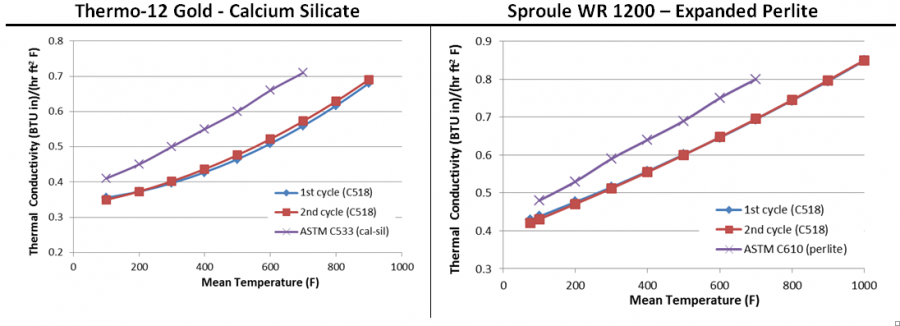

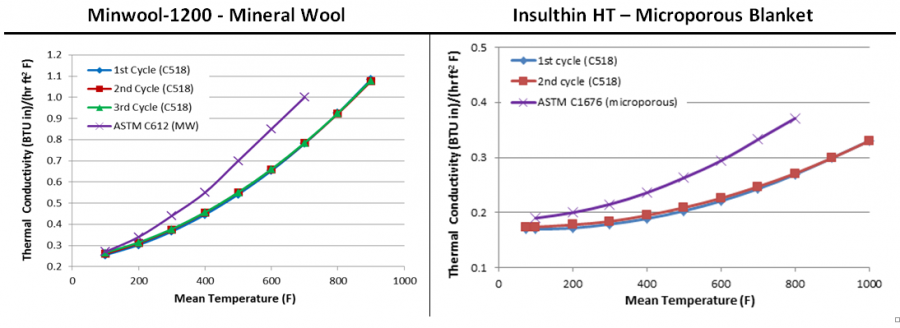

Each insulation was tested using the ASTM C518 standard test method: Standard Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus

The results from the more traditional insulations are consistent regardless of the length of exposure to high temperatures and are universally below their respective ASTM standard specifications for thermal performance (purple line).

The results from silica aerogel, however, show a dramatic decrease in thermal performance between the first…