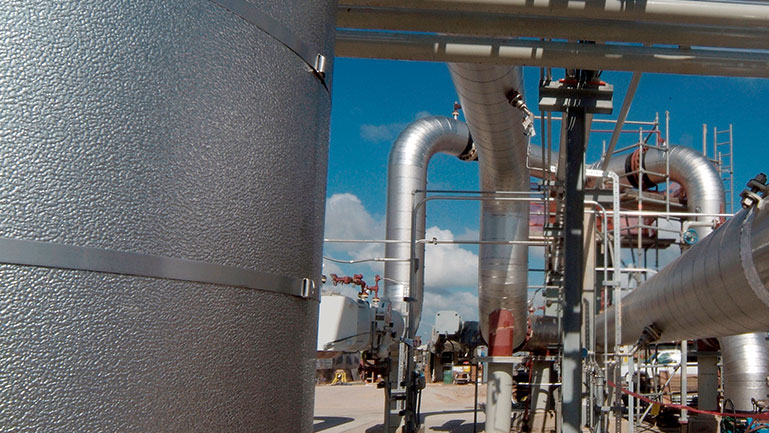

Industrial process cooling systems can operate at very cold and even cryogenic temperatures. At these temperature extremes, any flaws in the design or installation of the insulation system will quickly become apparent and could potentially damage the system. This is most commonly seen in the form of condensation forming on the outer jacketing or, in particularly bad situations, ice formation on (or in) the insulation. System design flaws also can cause material loss or pressure buildup because the liquefied material reverts back into its gaseous state.

This is why it is critical to design any industrial process cooling system to:

- Limit heat gain.

- Maintain a consistent temperature.

- Operate efficiently.

- Protect the Jacketing

This article explains the material considerations for insulating cryogenic systems, including using a polyfilm lined moisture barrier on the jacketing, to avoid system issues. Read more.