JM Corbond Closed-cell and Open-cell SPF

Johns Manville's complete line of spray polyurethane foam (SPF) insulation solutions provides superior thermal energy efficiency, as well as advanced air and sound control. SPF insulation can completely fill gaps and voids, works in hard-to-insulate areas, and can exceed the performance of traditional fiberglass insulation. Both Johns Manville SPF product categories, open-cell and closed-cell, deliver high yield, superior performance and exceptional sprayability.

Closed-cell Spray Foam

JM Corbond® IV Closed-cell SPF:

An HFO (hydrofluoroolefin) blown, closed-cell product that delivers high R-value per inch for superior thermal performance. JM Corbond IV was designed for use in states that prohibit the use of materials with a high Global Warming Potential (GWP) and hydrofluorocarbon (HFC) blowing agents. Corbond IV meets requirements for application in unoccupied attics and crawl spaces without a prescriptive ignition barrier or coating.

Use It For: New construction, remodels, basements, commercial buildings and many other applications in states that prohibit the use of materials with a high GWP and HFC blowing agents.

JM Corbond® 2.8 HFO Closed-cell SPF:

An HFO blown, 2.8 pcf closed-cell insulation designed for applications such as storage tanks, agricultural and other Class U buildings, underground and geological operations. The fourth-generation technology results in a low GWP and an Ozone Depletion Potential (ODP) of zero. Its high compressive strength and outstanding dimensional stability, superior thermal and moisture performance, and exceptional sprayability and adhesion make it an ideal choice for situations where a high-performance foam is paramount.

Use It For: Class U buildings such as those used for agriculture, storage tanks, underground facilities or geological applications such as pipe breakers and guard.

LEARN MORE

Open-cell Spray Foam

JM No Mix Open Cell (NMOC):

A two-component, low-density insulation system. It is specifically designed for insulating the interiors of commercial, residential and industrial buildings, and does not require mixing. With its consistent yield, superior thermal insulation and excellent air sealing properties, JM NMOC is an ideal choice for creating high-performing, energy-efficient buildings. It also provides an effective air barrier and exceptional adhesion, making it a great choice for walls, floors, ceilings, crawlspaces, unvented and vented attics.

Use It For: Interior commercial, residential and industrial applications.

LEARN MORE

TechConnect - Technical Support for Every Project

TechConnect is JM’s team of insulation experts who can help make your job easier. With FREE online, on-call and onsite service available wherever you are, the information you need is always accessible. Whether you need compliance answers, consultations, spec recommendations, online trainings, technical product assistance or something else, we have a range of services and solutions to keep your job moving.

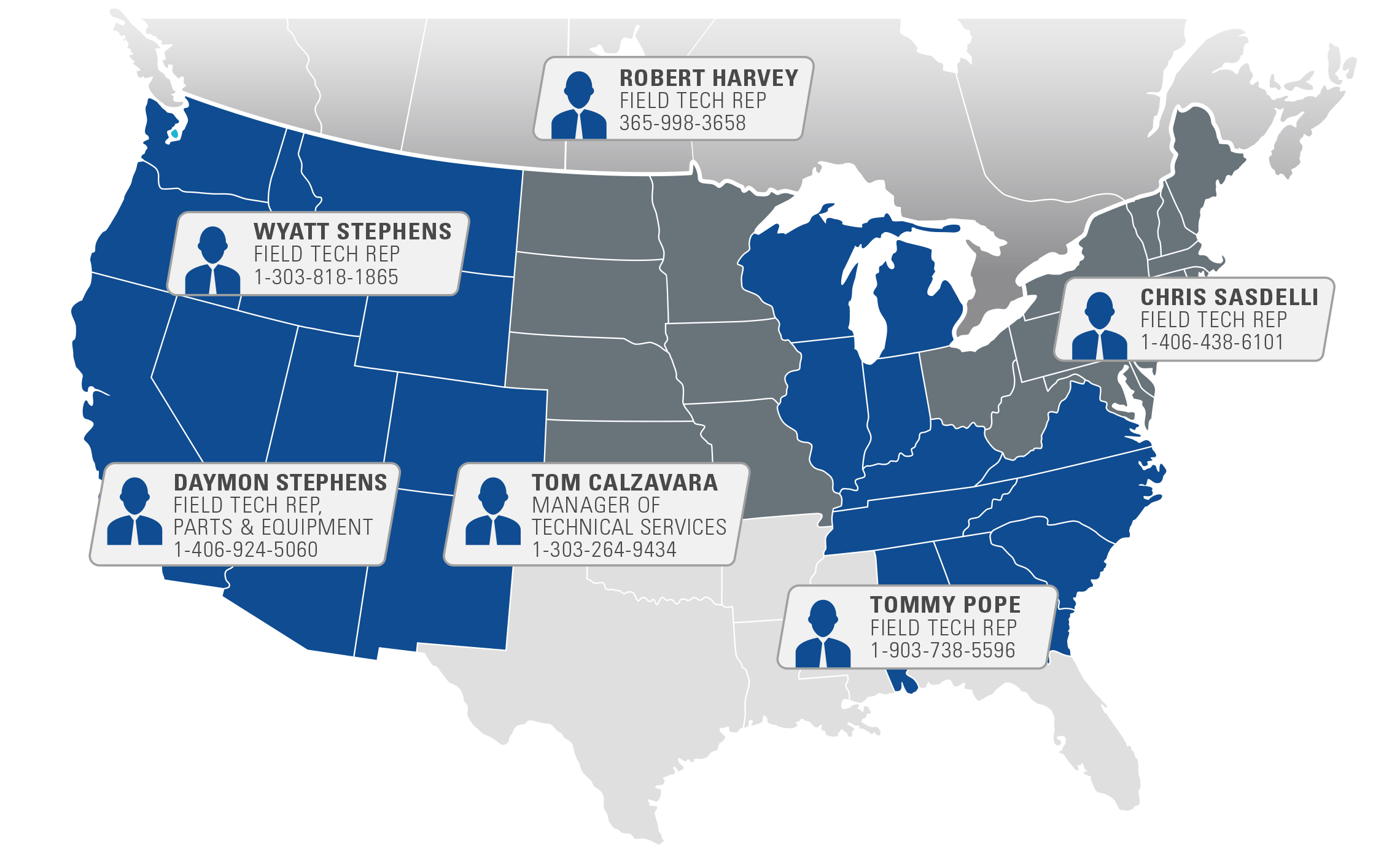

Spray Foam Parts & Equipment

We have on-staff experts dedicated to helping you select the right parts and equipment for your spray foam rig. Our spray foam team has access to an extensive catalog of spray foam parts and equipment with overnight shipping capabilities for emergencies. You can connect with our technical service representatives via phone, email, video calls or even text message to ensure you are ordering the correct parts.

Contact Information:

Daymon Stephens

Spray Foam Parts & Equipment Field Tech Rep

1-406-924-5060

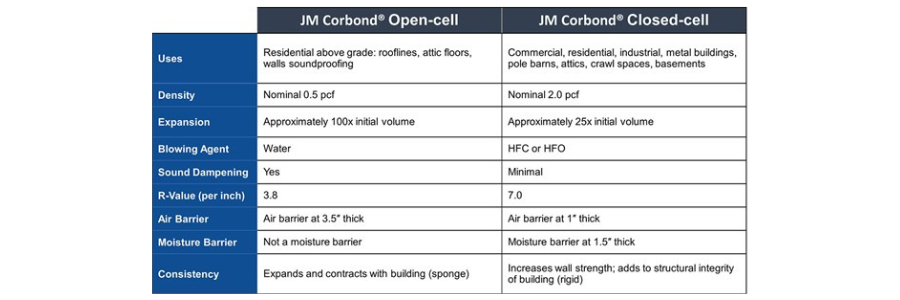

1. What is the difference between open-cell and closed-cell spray foams?

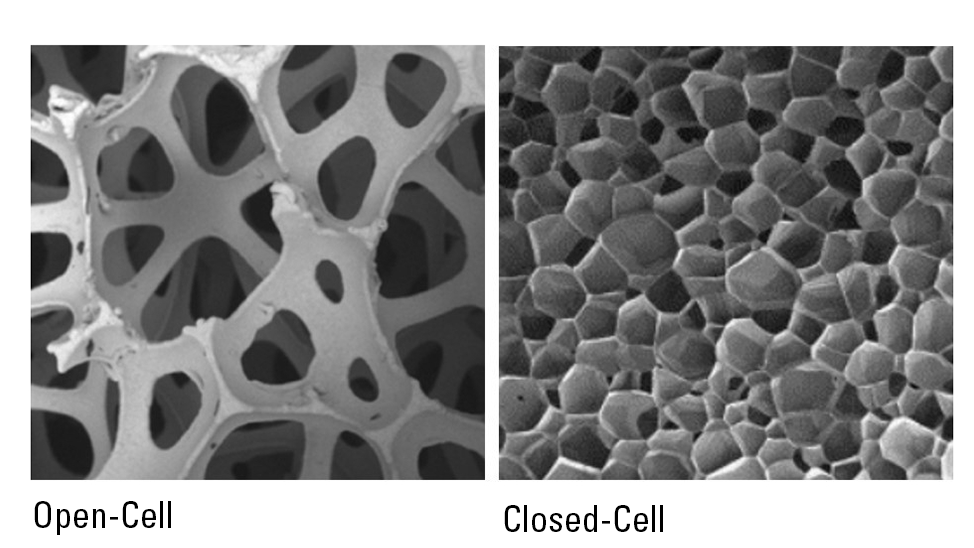

At the chemical and microscopic level, the two types of spray foam are vastly different and they each have different strengths and limitations. The generic term “spray foam” still appears on many specs, which might suggest that open-cell and closed-cell spray foam are interchangeable, but they’re not.

Open-cell spray foam is much less dense, expanding more as it is installed. It uses only water as a blowing agent to change it from a liquid to a foam solid. It has comparable thermal and acoustical properties to fiberglass but it’s also an air barrier at a minimum of 3.5 inches of thickness.

Closed-cell spray foam is denser and has a higher R-value. JM Corbond® closed-cell products have an R-value of 7.0 per inch. You need only one inch of closed-cell spray foam for it to be an air barrier and 1.5 inches for it to be a vapor barrier. It uses an HFC or HFO blowing agent to turn it from a liquid to a solid. It’s more rigid and makes the wall stronger. JM Corbond® IV closed-cell spray polyurethane foam (SPF) is a next-generation HFO-blown product that can be produced with a Global Warming Potential (GWP) of less than 2 and with an Ozone Depletion Potential (ODP) of zero.

Read our blog for more

2. Is spray foam the best choice for all insulation installs?

There’s no single insulation that’s right for all situations or all geographies. Closed-cell spray foam may not be appropriate in warmer climate zones, because it offers a higher R-value than is required by code in these areas. Spray foam also requires a clean, dry, sound substrate. Acoustic performance is also a factor. Your application may require a hybrid solution or a fibrous insulation.

3. Can spray foam be directly applied to heat-producing sources, like canned lights?

The in-service temperature for most spray foams is below 185°F. If you get above this temperature, there will be detrimental effects to the spray foam. So, for example, you can’t apply spray foam directly on pipe coming from a boiler. With spray foam, you also need to stay 3 inches away from heat sources. It is also recommended that fiberglass should not come in direct contact with heat sources.

4. Does spray foam offers similar acoustical benefits to fibrous insulation?

Open-cell spray foam provides acoustic benefits that are on par with fibrous insulations, closed-cell spray foam does not. Although closed-cell spray foam offers fewer acoustics benefits, it can provide an air barrier and higher R-values. Combining closed-cell spray foam with other types of fibrous insulation (in a hybrid system) will improve the acoustic performance of wall systems compared to closed-cell alone.

5. Is energy performance based solely on R-value?

Energy performance is actually a very broad term and it depends on many factors. R-value is a measure of how good a single material is at insulating. It’s a product-specific measurement and does not describe the energy performance of the entire wall because walls include components such as sheathing and penetrations that affect energy performance. The measure of the thermal performance of the entire wall assembly is called the U-value and it accounts for framing, sheathing, electrical boxes and all of the other components in a wall beyond the insulation.

Because framing has a lower R-value than insulation, the total U-value will be lower than you might expect based on the R-value of the insulation. A building designed with better air sealing, which can be provided by closed-cell and open-cell spray foam, can use a smaller HVAC system and will decrease energy consumption. Spray foam air seals and can reduce energy consumption when installed as the same R-value as a non-air barrier insulation.

6. Is cost per set the most important factor when selecting a spray foam product?

It is actually more important to determine the cost per board foot. Board feet is equal to (sq. ft.) x (installed thickness). Not all spray foam drums are 500 pounds. Some manufacturers put more or less liquid in their drums for various reasons, so a 520-pound drum would theoretically produce more foam than a 500lb drum of the same material, but may also be more expensive.

And drum set weight is not the only factor affecting spray foam installed cost. One of the most important factors affecting total cost is actually job site efficiency. If you want to reduce costs, it’s important to minimize time spent on the job site and difficulty during installation. So you need a product that will allow installers to work efficiently in many different conditions. A high-quality product is easier to install and won’t require applicators to spend much of their day troubleshooting. While this doesn’t affect board feet per set, it does affect total installation time and therefore overall costs.

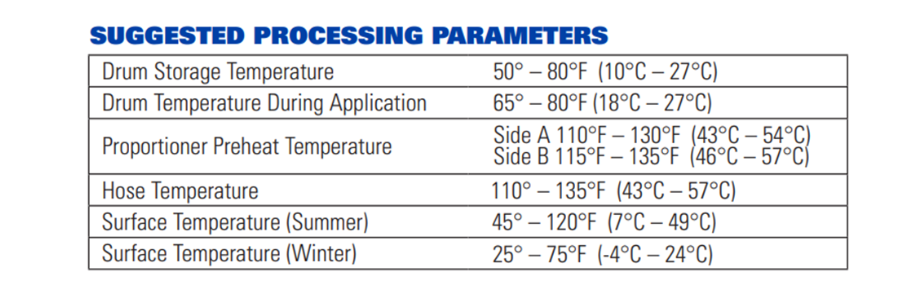

7. Can spray foam be applied in the winter?

Spray foam can be applied in a wide range of temperatures.

Closed-cell spray foam has summer blends and winter blends to offset the different substrate and ambient temperatures. If you’re applying foam in temperatures below 45°F, you need a winter formulation. Similarly, if you’re installing in a very hot, humid climate, you need a summer formulation. Temperature can also be controlled at the proportioner to account for more mild conditions or daily temperature swings.

Open-cell spray foam does not have a winter blend since it is not often installed in colder climates. It should not be installed below 45°F.

8. What is the difference between 3rd or 4th generation closed-cell spray foams?

Third generation closed-cell spray foams use hydrofluorocarbons (HFCs) as a blowing agent, while fourth generation closed-cell foams use a hydrofluoro-olefin (HFO) blowing agent.

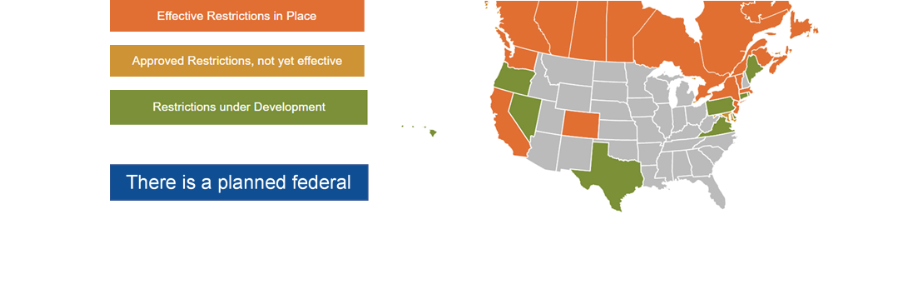

As states and countries work to combat global warming, they are phasing out the use of materials that have a high global warming potential (GWP), like HFCs. This impacts ALL 3rd generation spray foams. At the federal level HFCs are being phased out under regulations recently adopted by US EPA under the AIM Act. A federal phase-out is expected but the date is not yet finalized.

9. What is the difference in performance when installing thick passes versus multiple immediate passes of closed-cell foam?

Many spray foam manufacturers offer high-lift foams that can be installed in one single pass to high thicknesses. These high-lift products are intended to increase installation efficiency. However, there is more risk involved when using one thick pass versus multiple immediate passes. If you install one thick pass, the product may not be dimensionally stable or perform as well as multiple immediate passes. Installing one thick pass, which JM defines as greater than four inches, can compromise the quality of the installed foam. The foam can pull away from the framing, negating both the insulation and the air and vapor barrier benefits. If this occurs, the installer will have to go back and fix these gaps, which reduces installation efficiency significantly.

Check out the JM webinar and white paper for more information on this topic.

10. If you choose the right proportioner, are you guaranteed on-ratio spray foam?

There are many factors involved in creating on-ratio spray foam. Advances in technology are helpful and have been beneficial to the industry, but it’s important for installers to avoid complacency. The installer must always be aware of environmental and equipment conditions when installing spray foam to ensure that the foam on the wall is the proper ratio. For example, if there is additional moisture on the substrate, the foam on the wall can be off-ratio since the A-side reacts with water. An installer would be able to ascertain that by taking a core sample of the substrate. The bottom line is that there is no substitute for a skilled installer. There is no technology that will guarantee perfect, on-ratio application every single time.

11. Can I use two guns on one proportioner?

Running two guns on one proportioner is not recommended. There’s a perception that if the pressures from the two sides aren’t balanced, then you might be off ratio. In fact, the pressures on the A-side and B-side must be different because B-side is as much as three times thicker as the A-side, so it needs more pressure to move it through the system.

You can’t run two guns on one proportioner because if there is a restriction on one of the guns, it will adversely affect that gun as well as potentially the other gun. There’s just no way to monitor what’s going on with the two guns so we do not recommend this practice.

12. How much maintenance does spray foam equipment need?

It’s important to maintain a regular maintenance schedule for any tool and spray foam equipment is no exception. The most common problem applicators see is with their spray guns. The design of the spray guns themselves have been improved over the years, but they do still require maintenance. It’s also important to thoroughly clean your equipment if you’re moving between different drums, such as one manufacturer’s closed-cell to open-cell or any B-sides from different manufacturers.

Trainings about maintenance are available on JM.com under our TechConnect resource page.

13. How can I get education and help with installing spray foam?

You are not alone when you’re learning how to install spray foam. TechConnectSM is JM’s technical services team that is available 24/7. TechConnect is available for on-site training, assistance in setting up a new rig, troubleshooting issues more. TechConnect is available for free online, on-call and onsite support to JM customers using JM products.

Spray Foam R-Values and Performance

Understanding the GWP, ODP, and 3rd Generation Spray Foam Phase Out

Open-Cell vs. Closed-Cell Spray Foam

5 Tips for Cleaning and Maintaining Your Spray Foam Gun

The Originals

Using Immediate Passes to Optimize Spray Foam Installation