BUR Roofing Systems

- Family Description

-

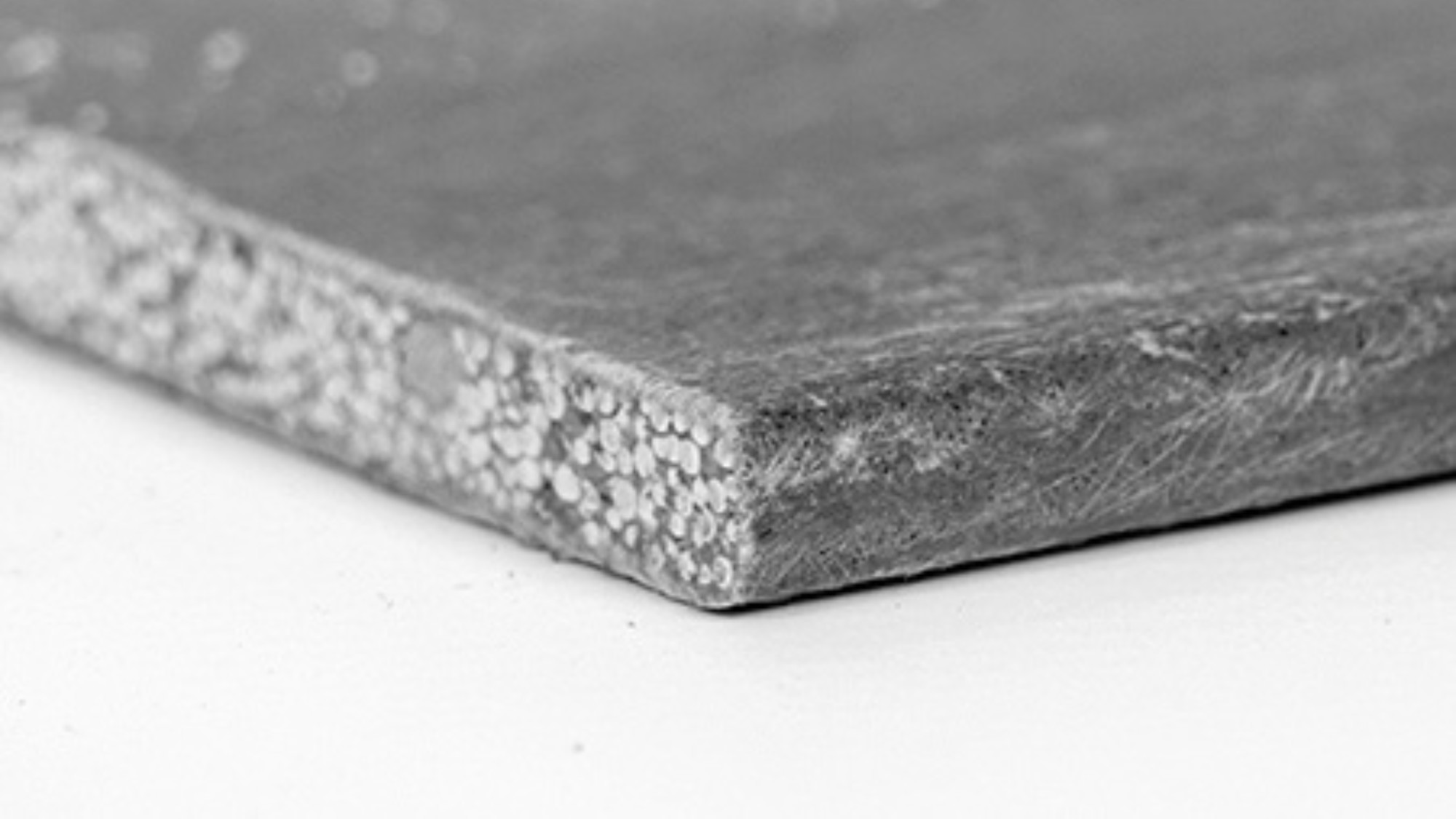

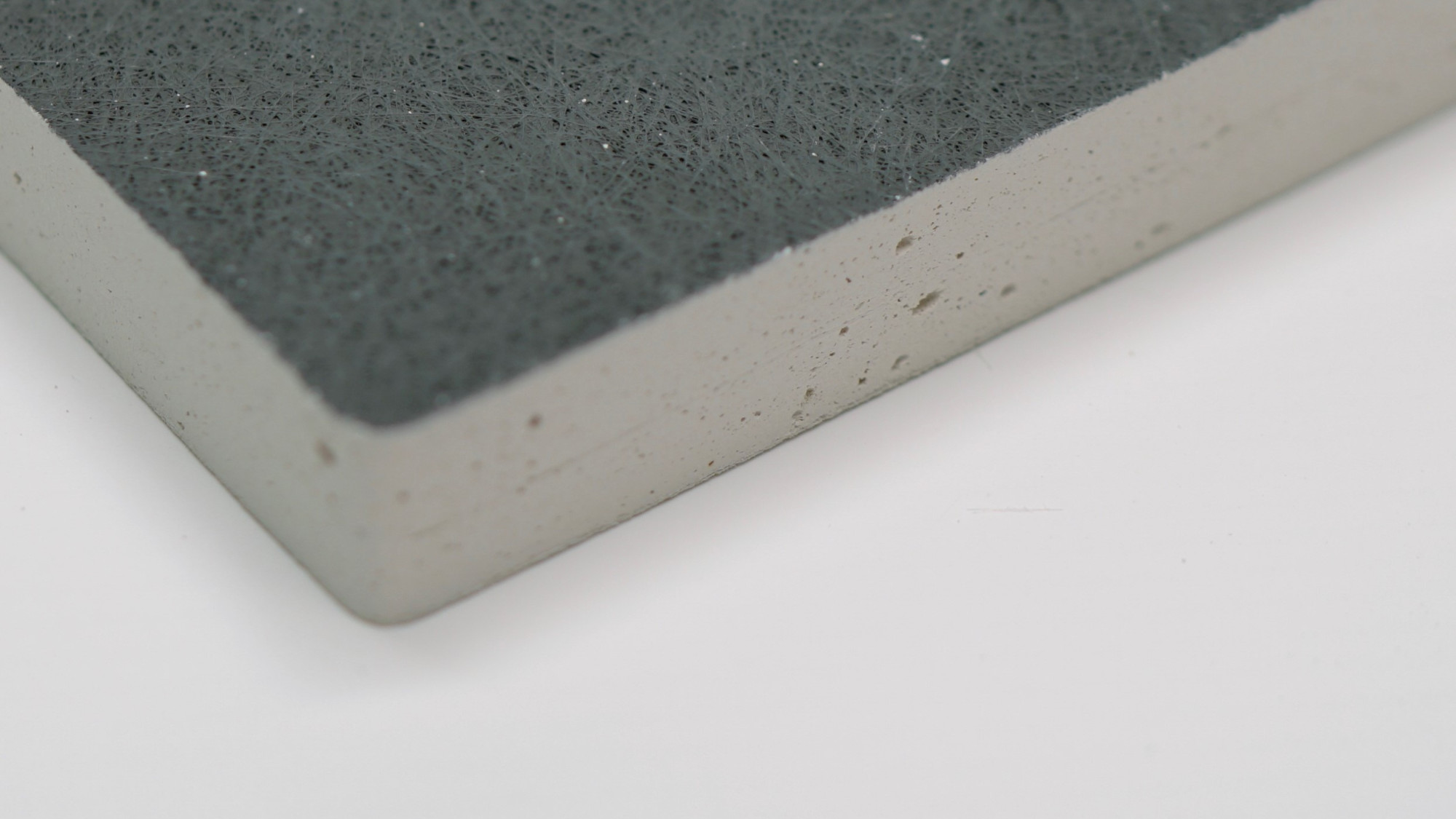

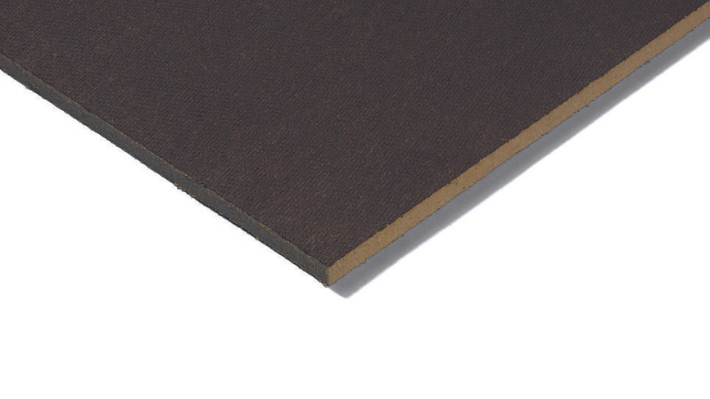

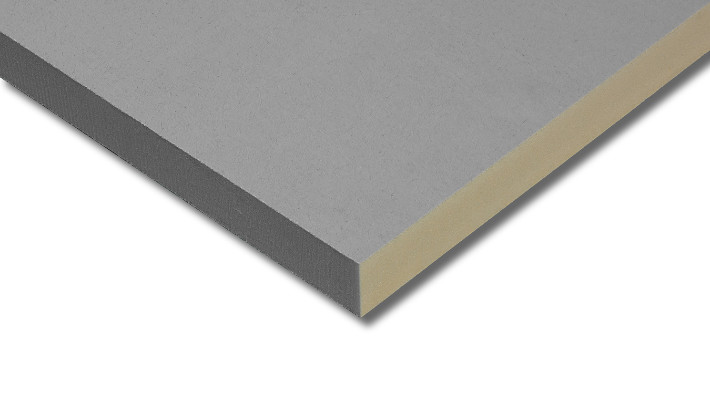

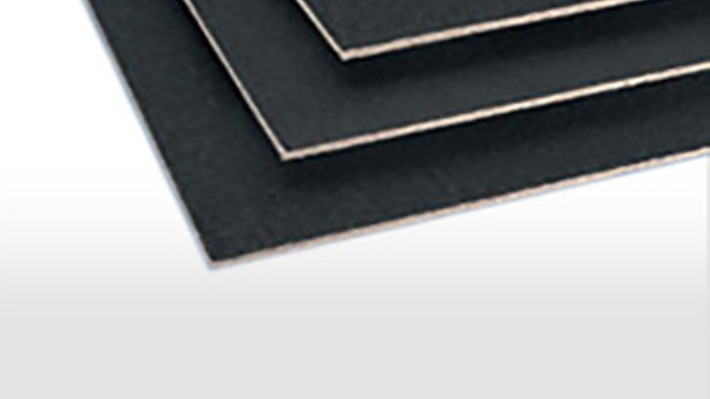

We pioneered built-up roofing systems in America more than 160 years ago. Our highly reliable waterproof membrane is field-fabricated with layers of bitumen, alternating with plies of reinforcing felts.

The redundant layers give roofs exceptional resistance to water and weather. As a result, we have long-lasting, durable and worry-free systems. Few roofing companies can claim to have created nearly one billion feet of BUR that are today under full guarantee.