We live in a world where massive amounts of data are collected every single day. In our data-centric society, one of the biggest challenges we face is learning how to extract the pertinent data from the white noise. We are inundated with information and opinions on products from company websites, blogs, advertisements, “expert” reviews, and more.

Though it takes a significant amount of effort to analyze all the information, we are fortunate that these resources are readily available. That being said, as product end users try to make educated decisions, it is important to understand how information is gathered, interpreted, and presented in order to make well-educated decisions.

For example, many of us closely consider expected gas mileage before purchasing a new car. Gas mileage is reported in city and highway data points because the amount of gas every car uses depends heavily on driving conditions. City driving results in lower gas mileage than highway driving because of stop-and-go traffic. A driver would be extremely disappointed if he or she expected highway performance in city driving conditions.

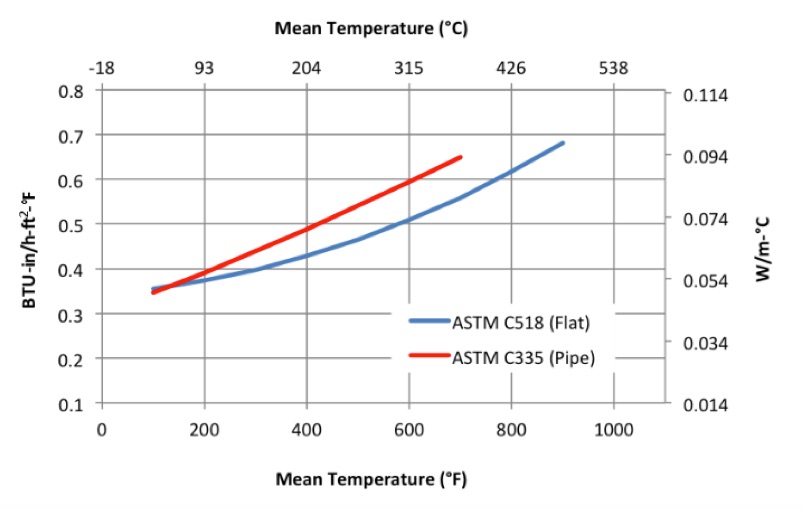

Similarly, industrial insulations can behave differently depending on the application conditions. For instance, insulations often have different installed thermal conductivity properties when they are used on pipes than when they are used on flat geometries. These differing results are clearly visible when the insulation’s thermal performance is tested via the ASTM C518 (Standard Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus) and ASTM C335 (Standard Test Method for Steady-State Heat Transfer Properties of Pipe Insulation) test methods.

When tested via the ASTM C518 test method, the insulation is compressed between two plates. One plate is heated to operating temperatures for several hours to determine how much heat passes through the insulation to reach the bottom plate. This heating environment typically represents a best-case-scenario for insulation applications – or, in other words, the ASTM C518 test method tests the “highway driving” performance of the insulation.

However, in the real world, insulations are not simply applied to flat geometries. In order to fully comprehend an insulation’s installed thermal performance, it must also be tested via the ASTM C335 test method. This method installs the insulation on a pipe, which is then heated to a steady operating temperature for several hours. Control guards are put in place at each end of the pipe to ensure the temperature remains consistent and the heat flows outward rather than longitudinally. This helps ensure the test method is indicative of a field application. In this environment, many insulations see a drop in thermal performance. Thus ASTM C335 represents the insulation’s performance in “city driving” conditions.

The discrepant results are caused by differences in installation and heat transfer properties between flat and round geometries. Therefore, just as one would not use highway gas mileage data to represent city driving conditions, one should not use flat thermal conductivities to specify insulation for pipe geometries. Using flat data for a pipe application could result in higher heat loss as well as higher surface temperatures than expected. Instead, it may be necessary to install additional insulation layers to achieve the desired thermal performance on a round pipe.

When it comes to thermal performance, it’s crucial to know whether the data you have been provided comes from ASTM C518 or C335. Capturing the relevant variables and understanding the intricacies of how the product performance specifications were calculated is critical to ensuring the performance you expect in real-world applications.

Look for parts 2 and 3 of the “Declutter the Data” series; we’ll talk about how to interpret ASTM C1617 (Standard Practice for Quantitative Accelerated Laboratory Evaluation of Extraction Solutions Containing Ions Leached from Thermal Insulation on Aqueous Corrosion of Metals) results and the startling new data pertaining to thermal shift and how it can affect your insulation system.