On the show floor, just beyond the demo noise. A product manager from a roofing membrane manufacturer taps the roll core with a knuckle and asks, “Will this carrier behave the same on day 4,000 as it does on day 4 - and will the roof still lie flat when the seasons start pulling?”

It’s the kind of question we heard more than once at the International Roofing Expo (Jan 20–22, Las Vegas). IRE is the annual hub where roofing and exteriors swap what works - hands‑on demos, real education, and conversations that calibrate the industry’s compass for the year ahead. We were there roaming the floor and the meeting rooms, listening for the decisions that shape materials upstream - on your production line - before anyone steps on a roof.

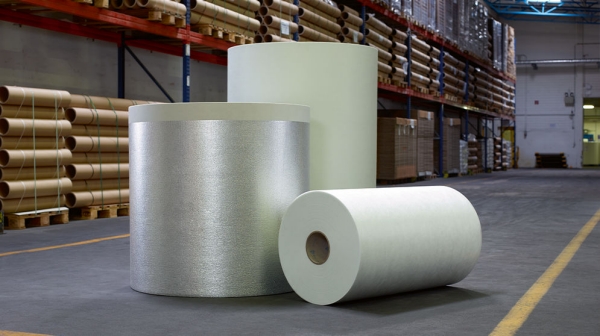

At Johns Manville Engineered Products, we engineer glass and polyester nonwovens that sit at the heart of modern roofing systems - carriers for modified bitumen membranes, glass mat facers for polyiso/gypsum deck boards and base mats for roofing shingles. We co‑develop with manufacturers, so the mat runs clean on the line and stays calm on the roof - stable, weldable, and ready for real‑world weather.

Below are three questions from IRE that manufacturers asked us most - and how our Evalith® fiberglass and polyester nonwovens help you answer them with confidence.

1) “Will the reinforcement keep the roof calm through seasons?”

What’s really being asked: When temperatures swing and a building moves, will the membrane resist wrinkling and creep, keep seams quiet, and preserve surface aesthetics?

How Evalith® helps bituminous roofing membranes:

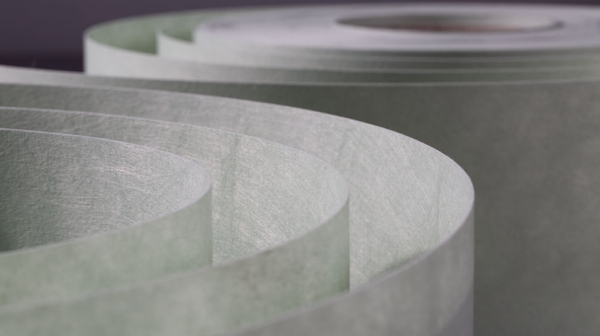

- Fiberglass mat carriers have no thermal memory, which helps sheets relax quickly and stay dimensionally stable after installation - translating to fewer wrinkles over time and seams that behave.

- Where a roof must flex with the structure, polyester spunbond adds elasticity and tear strength, helping the membrane stretch and recover rather than crack - useful in SBS systems designed for movement.

Rui Ferreira (Director Nonwovens Technology): “Owners never ask about tensile strength or dimensional stability. They are more concerned whether their roof will leak in ten years from wind or weather exposure. That's how JM's products pay dividends.”

2) “Will the deck facer protect the system when schedules - and weather - test it?”

What’s really being asked: Do the deck panels bring the bond strength, moisture/mold resistance, fire performance, and wind uplift confidence that keep the rest of the system out of trouble?

How Evalith® helps roof-deck panels:

- Evalith® fiberglass mat facers add mechanical integrity for dimensional stability and strength, support excellent adhesion to the core (less prone to delamination during installation), and their optimal density enables clean handling and precise cutting.

- Facers increase a panel’s resistance to water, mold, and fire, handle humidity and temperature swings, can be exposed to harsh environmental conditions during construction without deterioration, help protect against wind uplift, and are highly suitable for mechanically fastened systems.

Ellen Reed (Product Manager): “If the deck stays strong and the facer keeps its bond, the downstream layers can do their jobs - no drama at the edges, no surprises at inspection.”

3) “Will the shingle reinforcing mat stand up to storms - and the lab?”

What’s really being asked: Can the shingle substrate support wind uplift, tear resistance, fire performance, adhesion, weathering, and low temp flexibility - not just on test day, but across seasons?

How Evalith® helps roofing shingles:

- Evalith® fiberglass mat for roofing shingles provides a uniform, thin‑but‑strong substrate that accepts asphalt cleanly and supports tear strength and wind uplift resistance in the finished shingle - backed by consistent MD/CD behavior and binder systems that limit fiber shedding during production.

- The mat’s profile is designed for clean impregnation and reliable adhesion with the asphalt, including back‑side tape adhesion, helping shingles keep their shape and seal through weather exposure and seasonal temperature swings on the roof.

Rick Hausman (Commercial Leader): “Shingles have to stand up to wind, hail, and fire - and keep doing it for years. Our mats make those results dependable for manufacturers and reassuring for homeowners.”

Why manufacturers work with JM EP

- Performance that shows up on roofs: Evalith® carriers and facers are engineered for dimensional stability, strength, and environmental resistance - properties that translate into long life membranes, deck panels, and shingles.

- Strategic manufacturing in Europe & North America: Self‑sourced in fiberglass with nonwoven plants in Etowah, TN; Waterville, OH; Wertheim, Germany; and Steinach, Germany, plus polyester spunbond production in Spartanburg, SC; Berlin, Germany; and Bobingen, Germany - delivering supply security, shorter lead times, and flexible logistics worldwide.

- Service that goes the #JMextraMile: Multilingual customer and technical support, fast sampling, and application guidance across roofing markets.

Anna Fuhrbach (Portfolio Manager): “Specs are promises. Our job is helping you keep them - on the line, and years later on the roof.”

Put the questions to work

- Book a materials consult with our team.

- Bring your product targets and we’ll map Evalith® options to onroof outcomes - stability, adhesion, fire/wind/hail performance, and aesthetics.

-

Engineered ProductsInside IRE 2026: Three Manufacturing Questions We Heard. And How Evalith® Nonwovens Answer Them

-

Engineered Products

-

Engineered ProductsDon’t Look at What the Company Can Do for You – Look at What You Can Achieve with the Company

-

Engineered Products

-

Engineered Products

-

Engineered ProductsWhat Keeps Energy Flowing: The Unsung Role of Materials in Lead-Acid Battery Performance