When the gypsum industry met in Amsterdam for Global Gypsum Conference 2025, producers, suppliers, and technical experts gathered to exchange ideas on performance, sustainability, and innovation. Among the technical papers presented was one by Johns Manville’s Judith Hergert, Market Development Manager, and František Sabo, Global Innovation and Commercialization Manager. Their presentation explored how nonwovens facers and chopped fiberglass shape the boards that shape our buildings - and how JM helps producers stay ahead of market needs.

Judith Hergert

Market Development Manager

František Sabo

Global Innovation & Commercialization Manager

Setting the Scene

Gypsum boards are a backbone of modern construction used in homes, hospitals, schools, and high-rise offices for design flexibility, acoustic comfort, and fire safety. But behind that smooth surface lies a system of engineered materials.

Two components make a critical difference:

- Chopped fiberglass: reinforces the gypsum core for fire resistance, strength, and dimensional stability.

- Nonwoven facers: protect and support the board, provide fire resistance, manage moisture, and enable clean production.

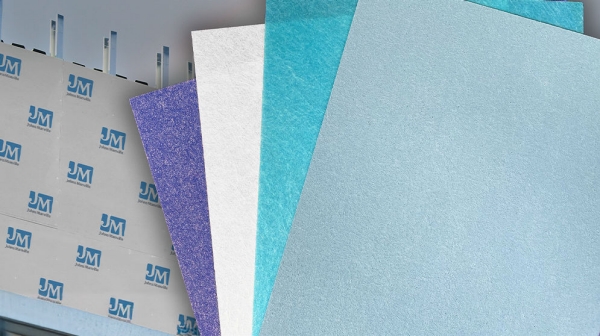

Johns Manville offers both. Our DuraCore® wet chopped fiberglass comes in two lengths with proprietary chemical sizing for optimal dosing and dispersion. Our coated and uncoated Evalith® fiberglass mats provide flexibility in area weight, color, and coating options, giving producers options to fine-tune performance and aesthetics.

Besides supplying these materials, we develop solutions tailored to the processes and raw materials of our customers, ensuring optimal performance in every application.

Fiber Control Drives Consistency

Fiberglass reinforcement is essential for fire resistance and mechanical strength, but its benefits depend on precise dosing and dispersion. That’s why Johns Manville has developed a comprehensive testing framework that mirrors real plant conditions to help producers achieve consistent quality and predictable performance:

- Gypsum Test Sample Preparation: Water, gypsum, and fiberglass are mixed under controlled conditions and cast into standardized molds. This ensures consistent material ratios and reliable test results for every evaluation.

- Flowability Measurement

- Flowmeter Test: A routine quality control method that measures flow behavior to monitor consistency and detect variations that could affect downstream processing.

- Advanced Flowability Assessment: Simulates gravimetric feeder principles to evaluate dosing stability by tracking vibrational patterns of the dosing unit, critical for preventing feeding interruptions.

- Visual Fiber Dispersion Test (Beaker Test): A quick, manual screening method where fiberglass is stirred in water and visually assessed for uniformity. This is very useful for initial checks.

- Standardized Dispersion Test: A controlled test that disperses a defined amount of fiberglass in water under set mixing conditions. Produces a sheet that visually reflects fiber distribution. This is more objective and repeatable than manual methods.

- Fire Resistance Evaluation

- Core Cohesion Test: A custom-built device simulating real fire exposure conditions to measure cohesion and structural stability of the gypsum core under thermal stress. Developed based on EN standards and customer feedback.

- Shrinkage Test: Measures dimensional changes in circular specimens before and after oven exposure to evaluate drying behavior and stability under heat.

- Mechanical Evaluation

- Flexural Strength Test: Three-point bending setup to determine maximum flexural load and assess reinforcement effects.

- Compression Test: Cube-shaped specimens tested under axial load to measure compressive strength and mix consistency.

These methods help improve board quality, ensure compliance with fire-rated specifications, and ultimately avoid production line downtimes.

Lesson from the floor: Consistency starts upstream and production challenges require the right partner. One who understands the process, delivers reliable solutions, and helps you stay ahead.

Facers Do More Than Cover

Glass nonwoven facers are functional components and JM’s Evalith® front and back facers deliver:

- Structural support

- Adhesion performance

- Production efficiency

- Moisture management

- Environmental resistance

- Safety contribution (due to fire resistance enhancement)

- Branding opportunities

And the advantages go deeper:

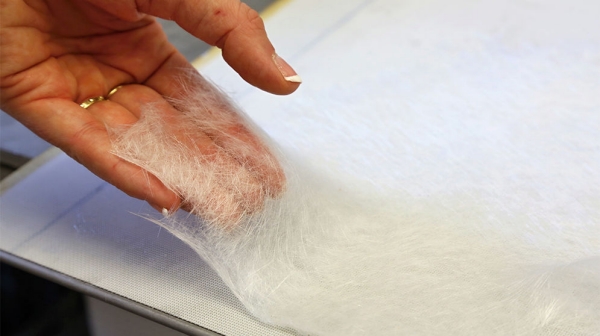

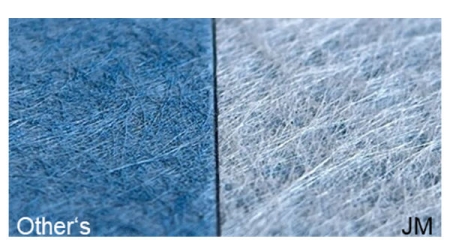

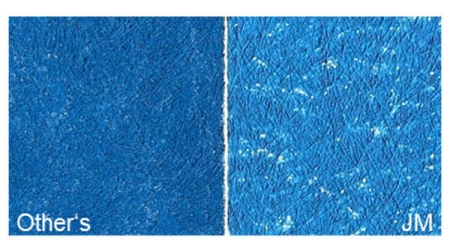

The structural reinforcement and improved bending stiffness of the board result from the presence of free, non-coated fibers on the facer's backside, which create strong mechanical interlocking and ensure excellent adhesion between the facer and the gypsum core. This design enhances resistance and helps maintain board integrity under thermal stress without adding stiffness to the facer itself.

Optimized slurry interaction without bleed-through is achieved through JM’s precisely engineered pore structure. This allows the gypsum slurry to penetrate the facer for a secure bond while preventing bleed-through, which enhances mechanical strength and can contribute to energy savings during the drying process.

Facers are tailored for specific board families – fireboards, exterior sheathing, shaft liners, roof decks - so producers can match facer properties to application needs.

The innovation process at JM begins with listening. Through close collaboration with customers, we identify market needs and opportunities that drive our R&D efforts. From initial insights to product design, scale-up, and full commercialization, every step is guided by practical application experience. Our advanced glass nonwovens manufacturing capabilities ensure that the final product meets technical requirements and delivers consistent performance on the production line. It’s this end-to-end partnership - from concept to implementation - that turns ideas into impactful solutions.

Lesson from the floor: Facers play a critical role - front and back - bringing performance and reliability to every board. But it’s the partnership behind the product that turns innovation into lasting market impact.

Sustainability Is a Business Imperative

As building codes evolve and customer expectations rise, sustainability has shifted from a differentiator to a business imperative. At JM, we go beyond supplying high-performance gypsum solutions - we partner with producers to help them achieve environmental goals through innovation and responsible practices:

Circular solutions: Internal scrap reuse and recycling units, and exploration of closed-loop systems.

Energy initiatives: Electrification, alternative fuels, and renewable energy to cut CO₂ emissions.

Documentation: JM has completed over 100 life cycle assessments (LCAs) for Evalith and DuraCore products, helping customers meet EPD requirements and certification goals.

Lesson from the floor: Sustainability is about compliance, but also about efficiency. Boards that weigh less, dry fast, and come with documented footprints give producers a competitive edge.

Ready to Take the Next Step?

Ask us about:

- Fiber and facer solutions to enhance board performance.

- Guidance on process consistency and material selection.

- Support for sustainability documentation and LCAs.

- Collaboration opportunities for new product development.

-

Engineered ProductsInside IRE 2026: Three Manufacturing Questions We Heard. And How Evalith® Nonwovens Answer Them

-

Engineered Products

-

Engineered ProductsDon’t Look at What the Company Can Do for You – Look at What You Can Achieve with the Company

-

Engineered Products

-

Engineered Products

-

Engineered ProductsWhat Keeps Energy Flowing: The Unsung Role of Materials in Lead-Acid Battery Performance