Back in the 1970s, before “streaming” meant anything other than rocket exhaust, Johns Manville was quietly working on a material that would survive the most extreme environment humans could imagine: outer space.

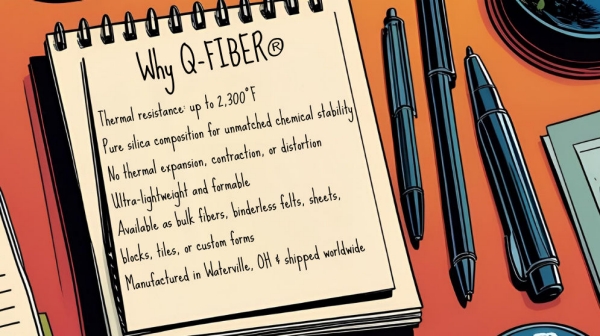

NASA needed something that could protect the space shuttle as it screamed back into Earth’s atmosphere at 17,000 mph (27,400 km/h) at temperatures soaring past 2,300°F (1,260°C). Most materials would just burn, melt, or warp under the strain. JM’s answer? Q-FIBER®. An exceptionally pure, amorphous silica fiber with zero thermal expansion, contraction, or distortion. In other words: it laughs in the face of extreme heat.

🚀 The Original Mission

Q-FIBER® became part of the shuttle’s tile sheathing as a critical layer of protection between NASA’s astronauts and the extreme heat of atmospheric re-entry. Lightweight yet resilient, it was space-age engineering at its finest.

💨 Today’s Mission: Filtration Without Compromise

Fast forward to today and Q-FIBER® hasn’t retired to a museum. It’s hard at work in different industries, including filtration. The same purity and thermal stability that once orbited the Earth now make it a go-to media in high-performance filtration systems.

For environmental test filters, analytical filtration systems, and other demanding filtration applications, Q-FIBER® bulk fibers offer unmatched stability and consistency. Produced from high-silica sand, impurities are removed and once it is heat-treated for structural integrity, Q-FIBER® delivers the low thermal conductivity, chemical stability, and structural resilience needed for precise, repeatable results even under extreme temperatures and rapid thermal cycling.

From capturing contaminants in high-heat chemical processes to ensuring ultra-pure air in cleanroom environments, Q-FIBER® resists degradation, shrinkage, and distortion, making it the ideal choice when filtration accuracy is non-negotiable.

🌟 Still a Star in Insulation

While Q-FIBER® shines in filtration, it remains a cornerstone in extreme-temperature insulation - the challenge it was originally born to solve. Aerospace, automotive, and industrial engineers continue to rely on its exceptional combination of low density, high thermal efficiency, and resistance to thermal shock. Here, Q-FIBER® is used both as bulk fibers and as ultra-clean binderless felts formed through a water deposition process, which makes it a trusted solution for applications ranging from spacecraft and aircraft components to heavy industrial equipment, cryogenics, and other environments where performance under extreme thermal stress is critical. Decades after its first mission, Q-FIBER® still earns its place in the most demanding insulation applications proving that space-grade engineering never goes out of style.

🪐 Why Q-FIBER® Remain Out of This World

Whether you’re protecting astronauts or purifying air in a cleanroom, Q-FIBER® delivers space-grade performance for Earth-bound challenges. And we still make them right here in Waterville, Ohio, USA.

-

Engineered ProductsInside IRE 2026: Three Manufacturing Questions We Heard. And How Evalith® Nonwovens Answer Them

-

Engineered Products

-

Engineered ProductsDon’t Look at What the Company Can Do for You – Look at What You Can Achieve with the Company

-

Engineered Products

-

Engineered Products

-

Engineered ProductsWhat Keeps Energy Flowing: The Unsung Role of Materials in Lead-Acid Battery Performance