Resources

Products

Spray Foam Insulation

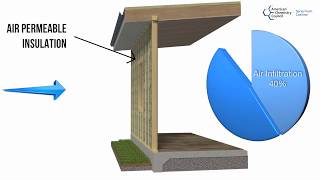

John Manville's complete line of spray polyurethane foam (SPF) insulation solutions provides superior thermal energy efficiency, as well as advanced air and sound control. SPF insulation completely covers gaps and voids, works in hard-to-insulate areas and can exceed the performance of traditional fiberglass insulation. Both Johns Manville SPF product categories, open-cell and closed cell, deliver high yield, superior performance and exceptional sprayability.

Spray Foam

JM Corbond High Yield Open-Cell

JM Corbond® High Yield Open-cell (HY OC) Spray Polyurethane Foam insulation is a two-component, low-density, E84 Class A rated, nonstructural insulation system designed for interior commercial, residential and industrial applications. JM Corbond HY OC is 100% water blown. JM Corbond HY OC offers the highest yield of any JM Corbond open-cell product. Its superior performance and exceptional sprayability make it an ideal choice for high-performing energy efficient buildings.

| SPF Acceptance Criteria | ASTM AC377 | Pass |

| Flame Spread | ASTM E84 | ≤ 25 |

| Smoke Development | ASTM E84 | ≤ 450 |

| Fungi Resistance | ASTM E283 | Pass |

| Dimensional Stability | ASTM D2126 | -8.8% Change in Volume |

| Core Density | ASTM D1622 | 0.4 pcf (normal) |

| Air Permeance | ASTM E2178-03 | < 0.02 (L/s)/m |

DATA SHEET

JM Corbond HY OC Data Sheet

JM Corbond HY OC Data Sheet (ES)

SDS

JM Corbond SDS - A

JM Corbond SDS - A (ES)

JM Corbond HY OC SDS - B

JM Corbond HY OC SDS - B (ES)

LITERATURE

Product Selector Guide

TechConnect Sell Sheet

JM Corbond High Yield Open-Cell FAQ

INSTALLATION INSTRUCTIONS

JM Corbond High Yield Open-Cell Installation Guide

JM Corbond High Yield Open-Cell Installation Guide (ES)

SPF Processing Parameters

SPF Change-over Procedure

SPF Change-over Procedure (ES)

SPF Safety Warning Sign

SPF Health and Safety Sheet

Corbond Daily Work Log

EVALUATION REPORTS

JM Corbond OC Code Compliance Research Report (CCRR-1079)

JM Corbond III

Johns Manville Corbond® III closed-cell spray polyurethane foam insulation offers and R-Value of R-7 per inch and can be applied in a single pass to a maximum of 3.5 inches, providing superior thermal performance with seamless air sealing and moisture control in a single step. Multiple immediate passes, with no wait time, may also be applied. With high yield and excellent adhesion, it's an ideal choice for high-performing energy efficient commercial, residential and industrial applications.

Advantages

Complete Coverage: Expands and adheres without shrinking or settling.

Energy-Efficient: Reduces air and moisture infiltration to the building envelope and provides continuous coverage for high thermal performance.

Air Barrier: Prevents leaks when installed at 1” thickness or more.

Moisture Performance: Resists mold growth; meets current vapor retarder codes.

Wide Application Temperature Range: Can be applied between 20°F and 120°F , delivering consistent performance with seasonal versatility.

Faster Installation: Spray easily in a single pass from a minimum of .5" to a maximum of 3.5”. Multiple immediate passes, with no wait time, may also be applied. See Data Sheet for complete information.

Commercial Approvals: NFPA 285 assembly approvals. Appendix X approval for application in unoccupied attics and crawl spaces without a prescriptive ignition barrier or coating.

| SPF Acceptance Criteria | ASTM AC377 | Pass |

| Flame Spread | ASTM E84 | ≤ 25 |

| Smoke Development | ASTM E84 | ≤ 450 |

| Fungi Resistance | ASTM C1388 | Pass |

| Dimensional Stability | ASTM D2126 | < 15% change in volume |

| Nominal Density | ASTM D1622 | 2 pcf |

| Closed-Cell Content | ASTM D6226 | > 90% |

| Compressive Strength (1”) | ASTM D1621 | 36 psi |

| Water Absorption | ASTM D2842 | 0.9% |

| Water Vapor Transmission | ASTM E96 | 0.61 perms @ 1.5" |

| Air Permeance | ASTM E2178-03 | 0.00055 (L/s)/m at 75 Pa |

| Sound Transmission | ASTM E90-90, ASTM E413-87 | 36 (STC) |

Data Sheet

SDS

JM Corbond SDS - A

JM Corbond SDS - A (ES)

JM Corbond Closed-cell SDS - B

JM Corbond Closed-cell SDS - B (ES)

Literature

Product Selector Guide

Exploring the Efficacy of High Lift Spray Foam Insulation White Paper

JM Spray Foam Overview Brochure

TechConnect Sell Sheet

JM Spray Foam Trial and Technical Support Brochure

JM Corbond III Seasonal FAQ

JM Spray Foam Parts and Equipment (Fusion AP)

STC Rating Documents

Acoustical Assemblies STC Rating Reference Guide

Installation Instructions

JM Corbond III SPF Installation Guide

SPF Processing Parameters

SPF Change-over Procedure

SPF Change-over Procedure (ES)

SPF Safety Warning Sign

SPF Health and Safety Sheet

Corbond Daily Work Log

Certificates

JM Corbond Re-Occupancy Certificate

JM Corbond Insulation Certificate

Spray Foam Certification

Technical Bulletins

JM Corbond III Air Barrier Advantage

Hybrid ccSPF + Fiberglass Wall Recommendations

Application Guides

Penetrations - Ambient Temperature

Below Grade Wall

Change in Substrate

Crawl Space

Expansion Joint

Floor Slab to Foundation Wall

Framed Floor to Foundation Wall

High Temperature Penetrations

Interstory Connections

Parapet

Substrate Joints and Defects

Unvented Attic Insulated Roof Deck

Unvented Attic Insulated Roof Deck V2

Vaulted Ceiling

Vented Attic

Wall Corner

Window Head

Evaluation Reports

Corbond III IAPMO Report

Environmental Product Declaration Spray Polyurethane Foam Insulation (HFC) Report

Life Cycle Assessment of Spray Polyurethane Foam Insulation Report

Specifications

JM Corbond III Greenguard

JM Corbond III Greenguard Gold

JM Corbond III

Case Studies

All-American House Case Study

Jay Peak Resort Case Study

Vision House Case Study

Project Profile

JM Corbond IV

JM Corbond® IV closed-cell spray polyurethane foam (SPF) is a next generation HFO blown, two-component, Class 1 rated, medium-density, SPF insulation system. JM Corbond IV is designed to insulate commercial, residential, and industrial buildings. The HFO technology allows JM Corbond IV to be produced with a low Global Warming Potential (GWP) and with an Ozone Depletion Potential (ODP) of zero. Its high yield, superior thermal and moisture performance, and exceptional sprayability and adhesion make it an ideal choice for high-performing energy efficient buildings.

| Flame Spread | ASTM E84 | ≤ 25 |

| Smoke Development | ASTM E84 | ≤ 450 |

| Fungi Resistance | ASTM C1388 | Pass |

| Dimensional Stability | ASTM D2126 | 12% change in volume |

| Core Density | ASTM D1622 | 2.0 lb/ft3 |

| Closed-Cell Content | ASTM D6226 | > 90% |

| Compressive Strength (1") | ASTM D1621 | 36 psi |

| Water Absorption | ASTM D2842 | 0.88% |

| Water Vapor Transmission | ASTM E96 | 0.61 perm at 1.5", 1.1 perm at 1" |

| Air Permeance | ASTM E2178-03 | 0.00055 (L/s)/m at 75 Pa |

| Sound Transmission | ASTM E90-90, ASTM E413-87 | 36 (STC) |

DATA SHEET

SDS

JM Corbond SDS - A

JM Corbond SDS - A (ES)

JM Corbond IV Closed-cell SDS - B

JM Corbond IV Closed-cell SDS - B (ES)

LITERATURE

Product Selector Guide

JM Corbond IV Guide

TechConnect Sell Sheet

INSTALLATION INSTRUCTIONS

JM Corbond IV Installation Guide

SPF Processing Parameters

SPF Change-over Procedure

SPF Change-over Procedure (ES)

SPF Safety Warning Sign

SPF Health and Safety Sheet

Corbond Daily Work Log

EVALUATION REPORTS

Environmental Product Declaration Spray Polyurethane Foam Insulation (HFO) Report

JM Corbond IV IAPMO Report (ER 0146)

CERTIFICATES

Project Profile

JM Corbond Open-cell

Johns Manville Corbond® Open-cell Spray Foam is a lower density, nonstructural insulation that offers an R-Value of R-3.8 per inch. It delivers high yield, minimizes sound transmission and virtually eliminates any air leakage. It's designed to improve energy efficiency for a wide variety of residential, commercial and industrial applications and can act as an effective air barrier.

Advantages:

Energy-Efficient: Helps to improve energy efficiency by filling in gaps and cracks while creating an air seal.

Air Barrier: Air-impermeable at 3.75”.

Sound Transmission: Performs well acoustically when used in an assembly.

Installation: Provides high yield with superior sprayability at an exceptional value and low odor. Meets requirements for application without an ignition barrier attics and crawl spaces.

| SPF Acceptance Criteria | ASTM AC377 | Pass |

| Flame Spread | ASTM E84 | ≤ 25 |

| Smoke Development | ASTM E84 | ≤ 450 |

| Fungi Resistance | ASTM E283 | Pass |

| Dimensional Stability | ASTM D2126 | < 15% change in volume |

| Nominal Density | ASTM D1622 | 0.5 pcf (normal) |

| Open-Cell Content | ASTM D6226 | > 92% |

| Water Vapor Transmission | ASTM E96 | 26.5 perms @ 2" |

| Air Permeance | ASTM E2178-03 | < 0.02 (L/s)/m |

| Sound Transmission | ASTM E90-90, ASTM E413-87 | 38 (STC) |

Data Sheet

JM Corbond oc SPF Data Sheet (US)

SDS

JM Corbond SDS - A

JM Corbond SDS - A (ES)

JM Corbond ocSPF SDS - B

JM Corbond ocSPF SDS - B (ES)

Literature

Product Selector Guide

JM Spray Foam Overview Brochure

JM Spray Foam Trial and Technical Support Brochure

TechConnect Sell Sheet

JM Corbond oc ocx Sell Sheet

JM Spray Foam Parts and Equipment (Fusion AP)

Spray Foam Certification

Specifications

Installation Instructions

JM Corbond oc SPF Processing Parameters

JM Corbond oc SPF Processing Parameters (ES)

JM Corbond® SPF Change Over Procedure

JM Corbond SPF Change-over Procedure (ES)

JM Corbond oc SPF Installation Guide

SPF Safety Warning Sign

SPF Health and Safety Sheet

JM Corbond Re-Occupancy Certificate

JM oc SPF for Unvented Attics Insulation Certificate

Unvented Attic Hatch Guide

Corbond Daily Work Log

Evaluation Reports

Code Compliance Research Report CCRR-1079

Environmental Product Declaration Spray Polyurethane Foam Insulation (HFC) Report

Life Cycle Assessment of Spray Polyurethane Foam Insulation Report

Certificates

JM Corbond OC SPF VOC Emission Test Certificate

JM Corbond Insulation Certificate

Case Study

Project Profile

No-Burn Plus ThB

Johns Manville has partnered with No-Burn, Inc. to offer No-Burn Plus ThB. This tintable white, thin film intumescent coating can be applied over JM open- and closed-cell polyurethane foams. When exposed to high temperatures and flame it intumesces, which creates a char-barrier to reduce heat transfer and surface burning in the event of a fire. This nontoxic, water-based coating complies with IRC and IBC and can serve in lieu of otherwise code-prescribed thermal barriers.

| Color | Opaque/White/Tinted |

| Finish | Flat |

| VOC Content | 18 g/L EPA Method 24 |

| Dry Time | 60-90 minutes |

| Pails | 5 gallons (19 L), 57.5 lbs. |

| Drums | 55 gallons (208 L), 632.5 lbs. |

| Shelf Life | 18 months |

| Cure Time | 24 hours |

| Boiling Point | 212°F |

| Freezing Point | 32°F |

| % Volatile by Volume | 33% |

| Specific Gravity | 1.25 |

Data Sheet

JM No-Burn Plus ThB Data Sheet

SDS

JM No-Burn Plus ThB White SDS

JM No-Burn Plus ThB SDS (ES)

JM No-Burn Black Tint SDS

JM No-Burn Black Tint SDS (ES)

No-Burn Plus ThB Custom Color Tint

No-Burn Plus ThB Custom Color Tint (ES)

No-Burn Plus ThB Gray

No-Burn Plus ThB Gray (ES)

No-Burn Plus ThB Dark Charcoal

No-Burn Plus ThB Dark Charcoal (ES)

Literature

Evaluation Report

Certificates

Bulletins

Spray Foam Parts and Equipment

We have on-staff experts designated to helping you select the right parts and equipment for your spray foam rig. Our spray foam team has access to an extensive catalog of spray foam parts and equipment with overnight shipping capabilities for emergencies. You can connect with our technical service representative via phone, email, video calls or even text message to ensure you are ordering the correct part. Click here for more details.