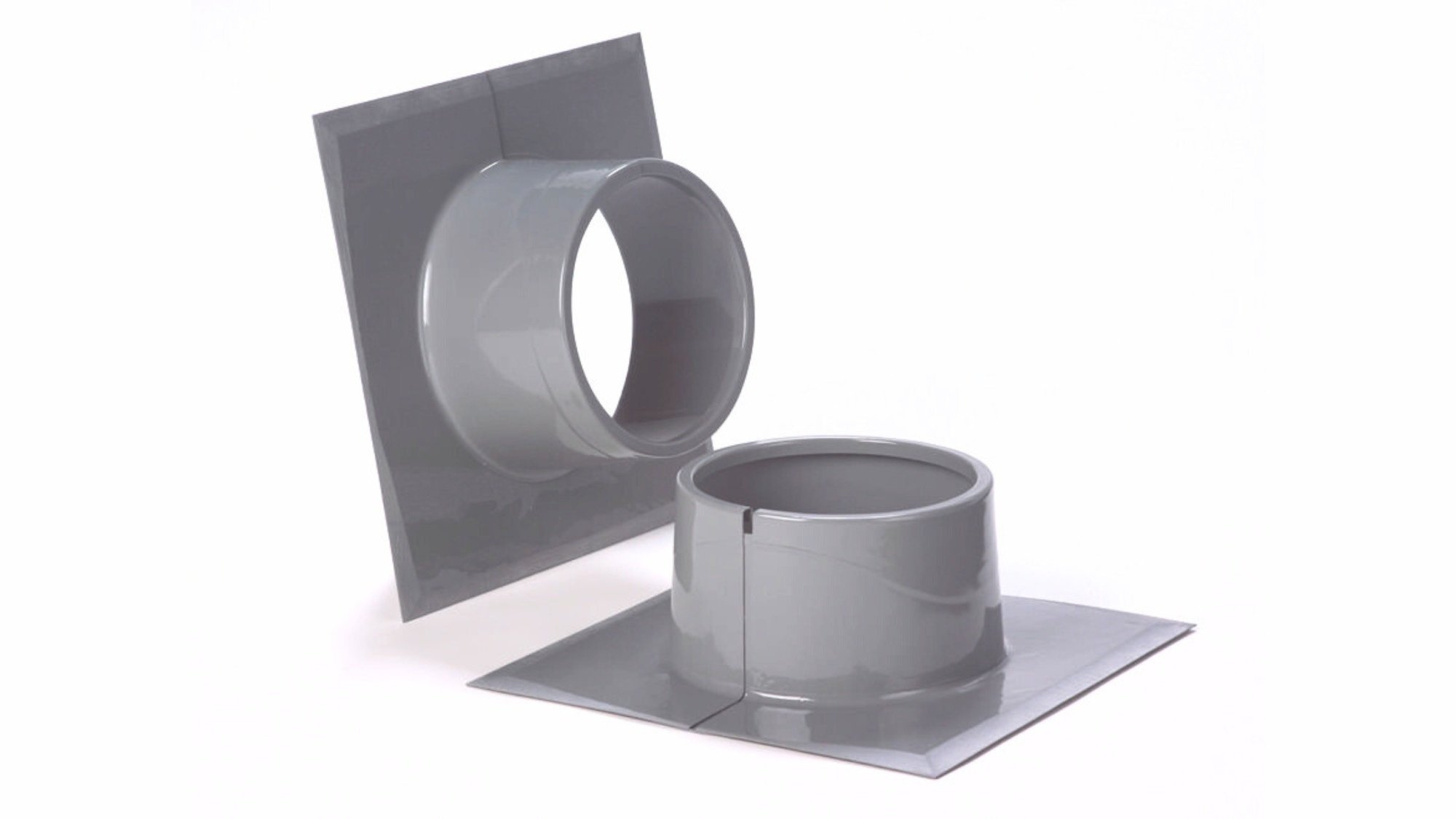

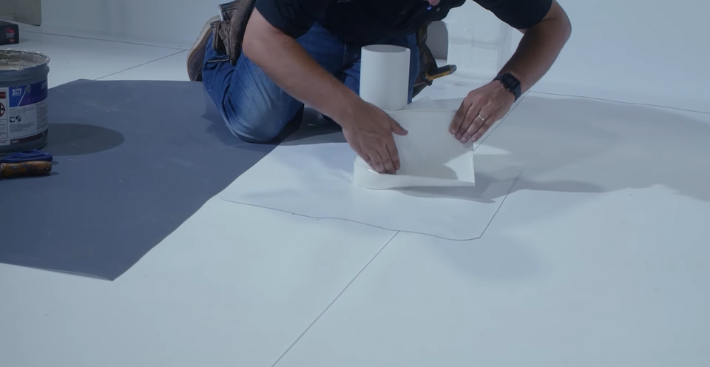

PVC Roofing Systems

PVC Roofing Systems

- Family Description

-

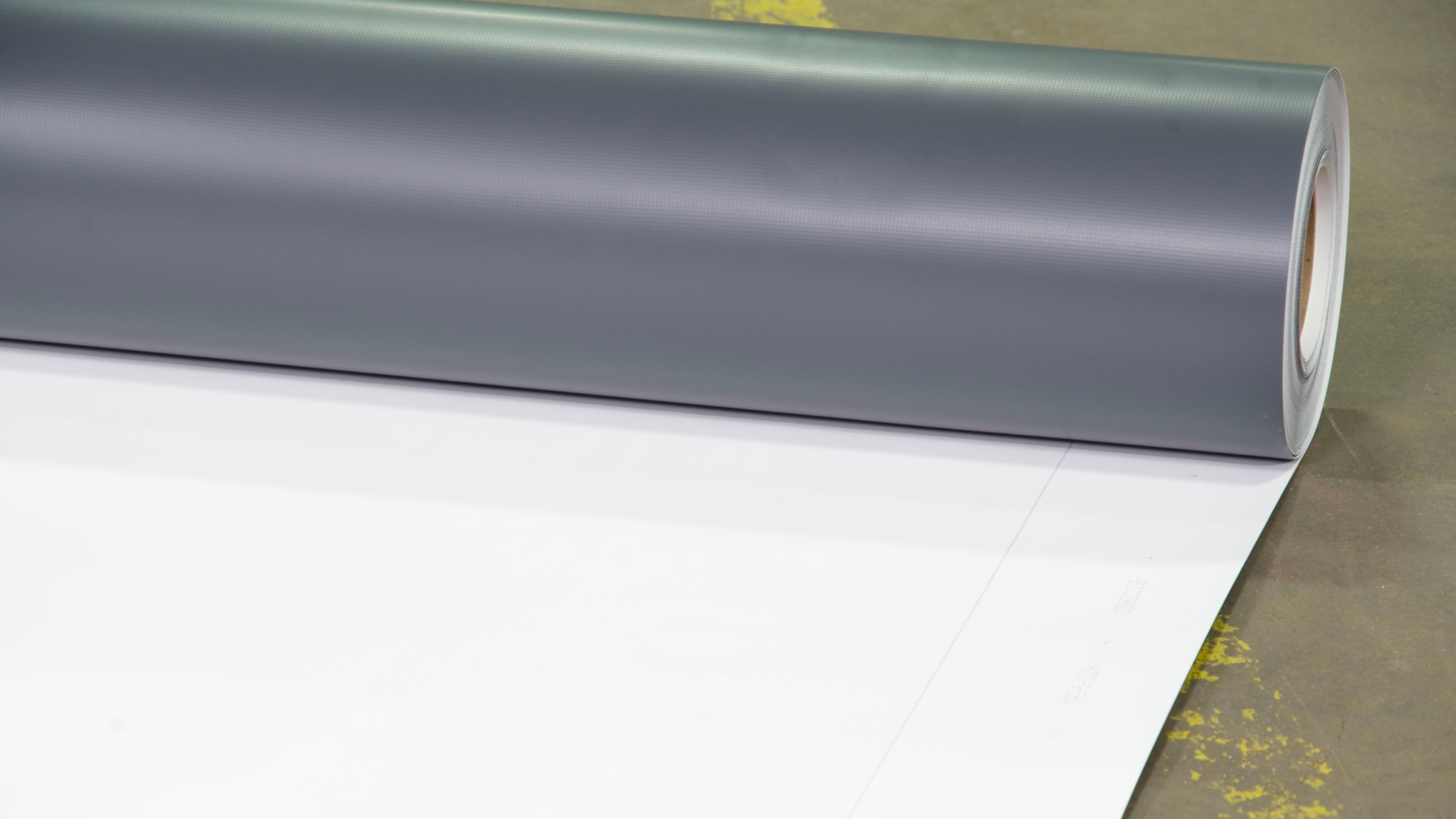

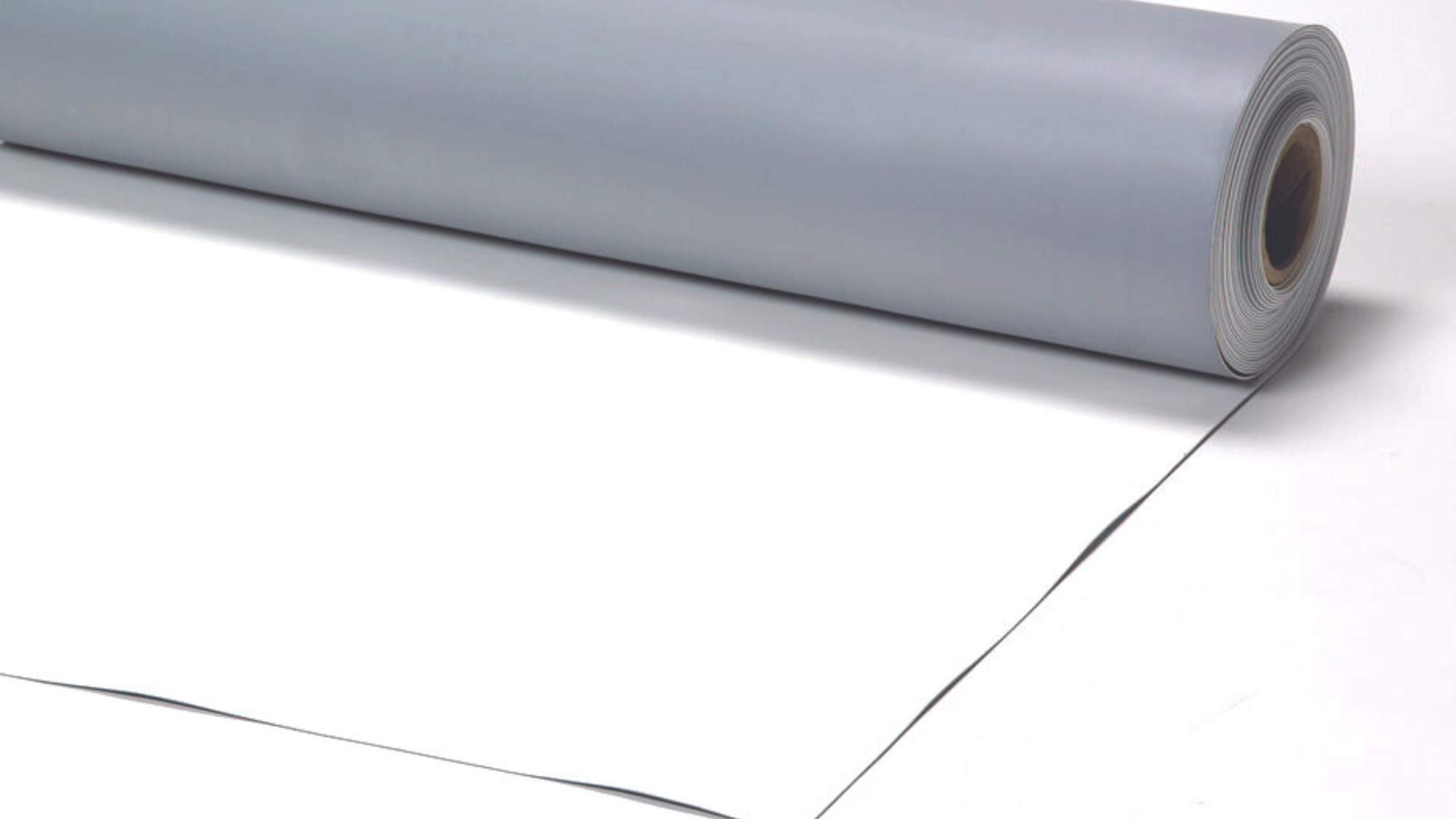

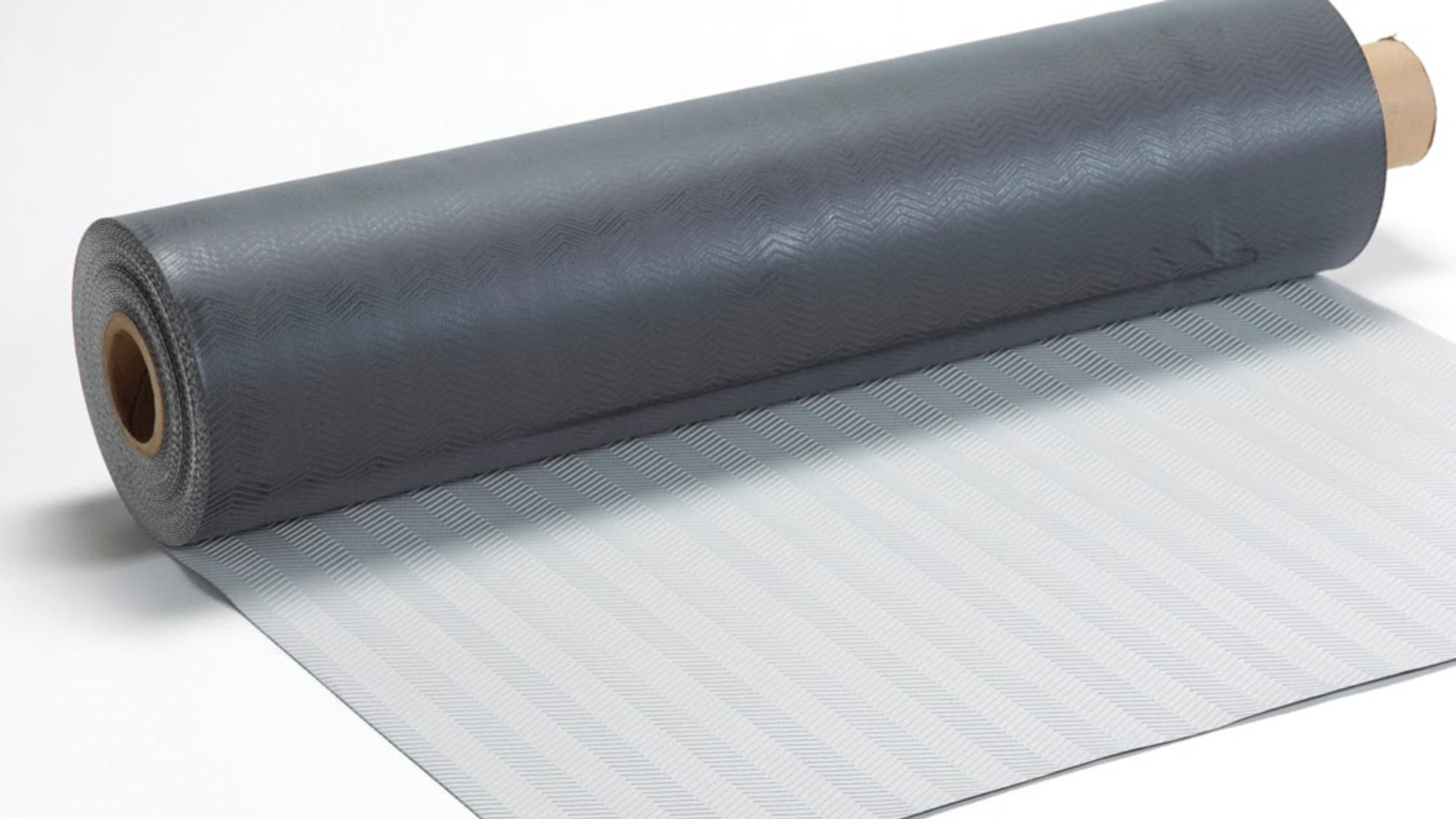

Built to withstand the test of time, our PVC roofing membranes are made to resist the toughest weather conditions and chemicals.

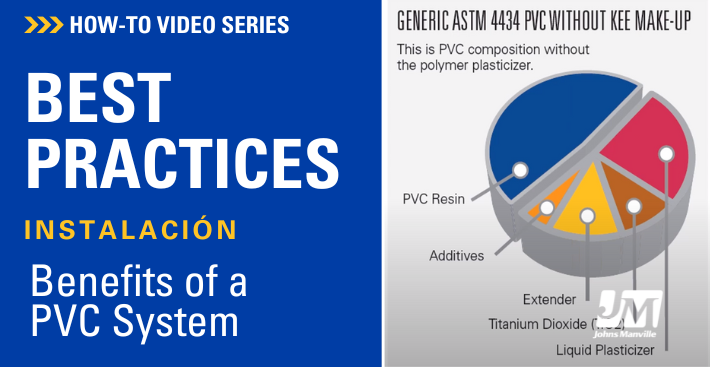

JM PVC with Dow Elvaloy® KEE and JM PVC SD Plus thermoplastic roofing membranes are manufactured using an ultraviolet-resistant polyvinyl chloride. Utilizing a polyester fabric reinforcement allows for systems to be both mechanically attached and adhered. PVC membranes deliver a pliable and durable sheet with excellent weathering characteristics and resistance to harsh chemicals and industrial pollutants.