Resources

Products

Commercial Building Insulation

Our complete commercial building insulation product line offers outstanding thermal and acoustical performance to help you maximize LEED® credits for the most sustainable structures. As your partner, Johns Manville is here to provide the products, resources, guidance and on demand support you need on the job.

Cavity-SHIELD Fiberglass

JM Formaldehyde-free™ Cavity-SHIELD™ fiberglass batts are made of long, resilient glass fibers bonded with a thermosetting resin. A wide range of thicknesses are available to provide NFPA 13 compliant passive fire protection in lieu of sprinklers for horizontal floor-ceiling cavities. Cavity-SHIELD fiberglass batts are available unfaced.

Advantages

Noncombustible: ASTM E 136, NFPA 13 Section 9.2.1 compliant

Simple Installation: no special equipment required

Cost-effective: economical alternative to blow-in insulation

Formaldehyde-free: will not off-gas formaldehyde in the indoor environment

Sound Control: reduces transmission of sound through floor or ceiling assemblies

Fire Resistant: Flame Spread of 25 or less and Smoke Developed of 50 or less (ASTM E84), Class A1

Durable Inorganic Glass: will not rot, mildew or deteriorate and is noncorrosive to pipes, wiring and sheet metal ducts

| ASTM Standards | ASTM C665 | Type I |

| Flame Spread | ASTM E84 | ≤ 25 |

| Smoke Development | ASTM E84 | ≤ 50 |

| Water Vapor Sorption | ASTM C1104 | 5% or less by weight |

| Odor Emission | ASTM C1304 | Pass |

| Corrosiveness | ASTM 665 | Pass |

| Fungi Resistance | ASTM C1388 | Pass |

| Combustion Characteristics | ASTM E136 | Pass |

Data Sheet

Literature

Certifications and Specifications

Warranties

Climate Pro Blow-In

Johns Manville Climate Pro® Formaldehyde-free™ blow-in, loose-fill fiberglass insulation offers thermal and sound control along with fire resistance. One bag of Climate Pro provides 77.1 square feet of R-30 coverage. Engineered for professional use with high-volume blowing machines, it's ideal for attics, nonconforming spaces and hard-to-reach areas making the job faster and easier.

Advantages

Easy Installation: Insulates attics or spaces of all shapes and sizes without cutting or fitting.

Complete Coverage: Effective in tight spaces, areas with large amounts of cross-bridging, or small gaps and voids.

Thermally Efficient: Effective resistance to heat transfer. No settling; no loss of R-value following installation.

Formaldehyde-free: Will not off-gas formaldehyde in the indoor environment.

Sound Control: Reduces sound transmission through exterior and interior walls, floor and ceiling assemblies.

Fire-Resistant: Flame Spread of 5 or less and Smoke Developed of 5 or less.

Resilient Inorganic Glass Fibers: No rotting, mildew or deterioration. Also noncorrosive to pipes, wiring and metal studs.

Superior Performance: Stable bonded glass fibers will not slump, settle or break down during normal applications.

| ASTM Standards | ASTM C764 | Type I |

| Flame Spread | ASTM E84 | ≤ 5 |

| Smoke Development | ASTM E84 | ≤ 5 |

| Critical Radiant Flux | ASTM E970 | > 0.12 W/cm2 (0.11 Btu/ft2s) |

| Water Vapor Sorption | ASTM C1104 | 5% or less by weight |

| Odor Emission | ASTM C1304 | Pass |

| Corrosiveness | ASTM C764 | Pass |

| Fungi Resistance | ASTM C1388 | Pass |

| Combustible Characteristics | ASTM E136 | Pass |

| VOC Emissions | ES Section 01350 | Pass |

Data Sheet

JM Climate Pro B7700 Data Sheet

Installation Instructions

JM Climate Pro B7700 Install Instructions

Climate Pro B-7700 Install Instructions Spanish

Climate Pro PresSure Gauge User Guide

SDS

Climate Pro Blow-In SDS

Climate Pro Blow-In SDS (ES)

Literature

Product Selector Guide

Blowing Wool Coverage Check and Easy Fix Checklist

Blowing Wool Coverage Check and Easy Fix Checklist (ES)

Certification and Specifications

Best Practices for Installing JM Climate Pro®

ComfortTherm

Johns Manville ComfortTherm® poly-encapsulated thermal and acoustical insulation offers R-Values up to R-30 and is available in precut batts to fit standard wall cavities or rolls for custom installation in any size of wall cavity. ComfortTherm® insulation is wrapped in plastic for dust-free, itch-free installation, and can be used in a wide variety of wood frame, engineered wood and steel frame construction applications, including new construction and retrofit.

Note: Color of product may differ based on the manufacturing location.

Advantages

Thermally Efficient: Effective resistance to heat transfer, with R-values up to R-30.

Formaldehyde-free: Will not off-gas formaldehyde in the indoor environment.

Sound Control: Reduces sound transmission through exterior and interior walls, floor and ceiling assemblies.

Fire-Resistant: Can be left exposed where building codes permit. Flame Spread of 25 or less and and Smoke Developed of 50 or less.

Resilient Inorganic Glass: No rotting, mildew or deterioration. Also noncorrosive to pipes, wiring and metal studs.

Superior Performance: Stable bonded glass fibers will not slump within the wall cavity, settle or break down during normal applications.

| ASTM Standards | ASTM C665 | Type II, Class A, Category 1 or 2 [Standard ComfortTherm is Category 1 (vapor retarder). ComfortTherm for hot, humid climates is Category 2 (non-vapor retarder).] |

| Flame Spread | ASTM E84 | ≤ 25 |

| Smoke Development | ASTM E84 | ≤ 50 |

| Water Vapor Permeance |

ASTM E96 | 0.5 Perms (29 ng/Pa-s-m2) |

| Water Vapor Sorption | ASTM C1104 | 5% or less by weight |

| Odor Emission | ASTM C1304 | Pass |

| Corrosiveness | ASTM 665 | Pass |

| Fungi Resistance | ASTM C1388 | Pass |

Installation Instructions

Fiberglass Installation Instructions

Fiberglass Installation Instructions (ES)

Literature

Warranties

FSK-25 Batts

Johns Manville Formaldehyde-free™ FSK-25 thermal and acoustical fiberglass insulation is available in R-Values up to R-30, and is offered in precut batts to fit standard wall cavities. FSK-25 faced batts combine fire resistance with excellent vapor resistance, and can be used in a wide variety of wood frame, engineered wood and steel frame construction applications, including new construction and retrofit. FSK-25 batts are designed with a foil facer that can be left exposed where codes permit.

Note: Color of product may differ based on the manufacturing location.

Advantages

Thermally Efficient: Effective resistance to heat transfer, with R-values up to R-30.

Formaldehyde-free: Will not off-gas formaldehyde in the indoor environment.

Sound Control: Reduces sound transmission through exterior and interior walls, floor and ceiling assemblies.

Fire-Resistant: Flame Spread of 25 or less and Smoke Developed of 50 or less. Can be left exposed where building codes permit.

Resilient Inorganic Glass: No rotting, mildew or deterioration. Also noncorrosive to pipes, wiring and metal studs.

Superior Performance: Stable bonded glass fibers will not slump, settle or break down during normal applications.

| ASTM Standards | ASTM C665 | Type III, Class A, Category I |

| Flame Spread | ASTM E84 | ≤ 25 |

| Smoke Development | ASTM E84 | ≤ 50 |

| Water Vapor Permeance Facing | ASTM E96 | 0.05 Perms (3 ng/Pa-s-m2) |

| Water Vapor Sorption | ASTM C1104 | 5% or less by weight |

| Odor Emission | ASTM C1304 | Pass |

| Corrosiveness | ASTM 665 | Pass |

| Fungi Resistance | ASTM C1388 | Pass |

Insul-SHIELD

Johns Manville Insul-SHIELD® is a series of flexible, semi-rigid or rigid thermal and acoustical fiberglass insulating boards for custom curtainwall applications. Insul-SHIELD is fire-resistant and noncombustible, available faced and unfaced, and designed to be used in new and retrofit construction, metal panel buildings and in general construction.

Advantages

Acoustically Efficient: Reduces transmission of sound through roofs, ceilings, floors and walls.

Fire-Resistant: Flame Spread of 25 or less and Smoke Developed of 50 or less.

Noncombustible: Unfaced I/S 150, I/S 300 and I/S 600 are non combustible.

Moisture-Resistant: Vapor-retarder facings resist water vapor transmission.

Noncorrosive: Prevents acceleration of corrosion to pipes, wiring and metal studs.

Durable: Will not rot, mildew or otherwise deteriorate, preventing slumping and uninsulated voids.

Easy to Handle: Lightweight; maintains its physical integrity during handling.

| ASTM Standards | ASTM C612 | Type IA or Type IB (IS150, IS300, IS600) |

| Flame Spread | ASTM E84 | ≤ 25 |

| Smoke Development | ASTM E84 | ≤ 50 |

| Max Use Temp | ASTM C411 | 350ºF |

| Water Vapor Sorption | ASTM C1104 | 5% or less by weight |

| Odor Emission | ASTM C1304 | Pass |

| Corrosiveness | ASTM C665 | Pass |

| Fungi Resistance | ASTM C1388 | Pass |

| Combustion Characteristics | ASTM E136 | IS150, IS300, IS600: Pass; Black IS300, IS600: Pass |

| 10% Linear Shrinkage | ASTM C356 | None |

Kraft Faced Fiberglass

Johns Manville Formaldehyde-free™ Kraft-faced thermal and acoustical insulation offers R-Values up to R-49, and is offered in precut batts to fit standard wall cavities or rolls for custom installation in any size cavity. Kraft-faced insulation is ideal for moisture control in exterior walls, reduces sound transmission through walls, ceilings and floors, and can be used in a variety of wood-framed, engineered wood and steel frame construction applications, including new construction and retrofit.

Note: Color of product may differ based on the manufacturing location.

Advantages

Thermally Efficient: Effective resistance to heat transfer, with R-values up to R-49.

Formaldehyde-free: Will not off-gas formaldehyde in the indoor environment.

Sound Control: Reduces sound transmission through exterior and interior walls, floor and ceiling assemblies.

Resilient Inorganic Glass: No rotting, mildew or deterioration. Also noncorrosive to pipes, wiring and metal studs.

Superior Performance: Stable bonded glass fibers will not slump within the wall cavity, settle or break down during normal applications.

| ASTM Standards | ASTM C665 | Type II, Class C, Category 1 |

| Water Vapor Permeance Facing | ASTM E96 | 1.0 Perms (57 ng/Pa-s-m2) |

| Water Vapor Sorption | ASTM C1104 | 5% or less by weight |

| Odor Emission | ASTM C1304 | Pass |

| Corrosiveness | ASTM 665 | Pass |

| Fungi Resistance | ASTM C1388 | Pass |

Data Sheet

Kraft Faced Fiberglass Data Sheet

SDS

Kraft Faced Fiberglass SDS

Kraft Faced Fiberglass SDS (ES)

Certifications and Specifications

Installation Instructions

Fiberglass Installation Instructions

Fiberglass Installation Instructions (ES)

High Performance Unvented Attic: Install for Performance

Literature

Warranties

Panel Deck FSK-25

Johns Manville Panel Deck FSK-25 Formaldehyde-free™ thermal and acoustical insulation is available in R-Values up to R-30 and combines fire resistance with an excellent vapor retarder. Panel Deck FSK-25 insulation is offered in precut batts with extra-wide tabs for modular roof deck applications and other speciality commercial applications. This product is designed with a foil facer that can be left exposed where codes permit.

Note: Color of product may differ based on the manufacturing location.

Advantages

Thermally Efficient: Effective resistance to heat transfer, with R-values up to R-30.

Formaldehyde-free: Will not off-gas formaldehyde in the indoor environment.

Sound Control: Reduces sound transmission through exterior and interior walls, floor and ceiling assemblies.

Fire-Resistant: Flame Spread of 25 or less and Smoke Developed of 50 or less. Can be left exposed where building codes permit.

Resilient Inorganic Glass: No rotting, mildew or deterioration. Also noncorrosive to pipes, wiring and metal studs.

Superior Performance: Stable bonded glass fibers will not slump, settle or break down during normal applications.

| ASTM Standards | ASTM C665 | Type III, Class A, Category I |

| Flame Spread | ASTM E84 | ≤ 25 |

| Smoke Development | ASTM E84 | ≤ 50 |

| Water Vapor Permeance Facing | ASTM E96 | 0.05 Perms (3 ng/Pa-s-m2) |

| Water Vapor Sorption | ASTM C1104 | 5% or less by weight |

| Odor Emission | ASTM C1304 | Pass |

| Corrosiveness | ASTM 665 | Pass |

| Fungi Resistance | ASTM C1388 | Pass |

Spider Plus Blow-In

Johns Manville Spider® Plus Formaldehyde-free™ blow-in fiberglass insulation uses interlocking fiber technology to fill all gaps and voids quickly with no adhesive or netting for a faster installation. Spider Plus provides complete coverage, with no shrinking or settling, resulting in superior thermal performance and sound control. Designed for use in wood- and metal-frame construction, engineered- wood construction and manufactured homes.

Advantages

Fast Drying: Dries immediately once installed.

Complete Coverage: Effective in tight spaces, areas with large amounts of cross-bridging or small gaps and voids.

Thermally Efficient: Effective resistance to heat transfer, with R-values up to R-25 in a 6'' cavity.

Formaldehyde-free: Will not off-gas formaldehyde in the indoor environment.

Sound Control: Reduces sound transmission through exterior and interior walls, floor and ceiling assemblies.

Fire-Resistant: Flame Spread of 25 or less and Smoke Developed of 50 or less.

Resilient Inorganic Glass: No rotting, mildew or deterioration. Also noncorrosive to pipes, wiring and metal studs.

| ASTM Standards | ASTM C764 | Type I |

| Flame Spread | ASTM E84 | ≤ 25 |

| Smoke Development | ASTM E84 | ≤ 50 |

| Critical Radiant Flux | ASTM E970 | > 0.12 W/cm2 (0.11 Btu/ft2s) |

| Water Vapor Sorption | ASTM C1104 | 5% or less by weight |

| Odor Emission | ASTM C1304 | Pass |

| Corrosiveness | ASTM 665 | Pass |

| Fungi Resistance | ASTM C1388 | Pass |

| Combustion Characteristics | ASTM E136 | Pass |

Data Sheet

Spider Plus Blow-In Data Sheet

SDS

Spider Plus Blow-In SDS

Spider Plus Blow-In SDS (ES)

Sell Sheet

Spider Plus Blow-In Sell Sheet

Certifications and Specifications

Installation Instructions

Spider Plus Consolidated Install Instructions

Spider Plus Consolidated Install Instructions (ES)

Spider Plus Full Install Instructions

Spider Plus Full Install Instructions (ES)

Coverage Card

Spider PLUS Closed Cavities Coverage Card

Literature

Case Study

Unfaced Fiberglass

Johns Manville Formaldehyde-free™ Unfaced thermal and acoustical insulation offers R-Values of up to R-49, and is offered in precut batts to fit standard wall cavities or rolls for custom installation in any size cavity. Unfaced insulation reduces sound transmission through walls, ceilings and floors, and can be used in a variety of wood frame, engineered wood and steel frame construction applications, including new construction and retrofit.

Advantages

Thermally Efficient: Effective resistance to heat transfer, with R-values up to R-49.

Formaldehyde-free: Will not off-gas formaldehyde in the indoor environment.

Sound Control: Reduces sound transmission through exterior and interior walls, floor and ceiling assemblies.

Fire-Resistant: Flame Spread of 25 or less and Smoke Developed of 50 or less.

Resilient Inorganic Glass: No rotting, mildew or deterioration. Also noncorrosive to pipes, wiring and metal studs.

Superior Performance: Stable bonded glass fibers will not slump within the wall cavity, settle or break down during normal applications.

| ASTM Standards | ASTM C665 | Type I |

| Flame Spread | ASTM E84 | ≤ 25 |

| Smoke Development | ASTM E84 | ≤ 50 |

| Water Vapor Sorption | ASTM C1104 | 5% or less by weight |

| Odor Emission | ASTM C1304 | Pass |

| Corrosiveness | ASTM 665 | Pass |

| Fungi Resistance | ASTM C1388 | Pass |

| Combustion Characteristics | ASTM E136 | Pass |

Installation Instructions

Fiberglass Installation Instructions

Fiberglass Installation Instructions (ES)

High Performance Unvented Attic: Install for Performance

Literature

STC Rating Documents

Acoustical Assemblies STC Rating Reference Guide

Certifications and Specifications

JM CladStone Water & Fire Block Mineral Wool

Johns Manville CladStone™ Water & Fire Block insulation is manufactured from inorganic fibers derived from volcanic rock. Advanced manufacturing technology ensures consistent product quality, with high-fiber density and low shot content for excellent performance. Noncombustible, with water-repellent properties, it is ideal for exterior cavity wall and rainscreen applications. Available in 4 densities, CladStone 45 (4.5pcf), CladStone 60 (6.0 pcf), CladStone 80 (8.0 pcf) and CladStone 110 (11.0 pcf).

Advantages

Water-Repellent: Repels water to ensure drainage when applied as part of a proper exterior wall cavity system.

Fire-Resistant: Melting point in excess of 2000˚F (1093˚C). Flame Spread of 0 and

Smoke Developed of 0.

Durable Inorganic Glass: No growth of fungi. No sustaining of vermin.

Densities: CladStone 45 (4.5pcf), CladStone 60 (6.0 pcf), CladStone 80 (8.0 pcf) and CladStone 110 (11.0 pcf)

| ASTM Standards | ASTM C665 | Type I |

| Thermal Resistance | ASTM C518 | R-4.3 per inch |

| Flame Spread | ASTM E84 | 0 |

| Smoke Development | ASTM E84 | 0 |

| Water Vapor Permeance Facing | ASTM E96 | Unfaced, 50 perms as tested |

| Water Vapor Sorption | ASTM C1104 | Absorbs 0.03% by volume |

| Odor Emission | ASTM C1304 | Pass |

| Corrosiveness | ASTM C665 | Pass |

| Fungi Resistance | ASTM C1338 | Pass |

| Combustion Characteristics | ASTM E136 | Pass |

| ASTM C612 | Type IA, IB, II, III, IVA, IVB | |

| ASTM C356 | Linear shrinkage < 2% 1200° F (650° C) | |

| ASTM C1335 | Shot content less than 25% |

Data Sheet

JM CladStone 45 Water & Fire Block Data Sheet

JM CladStone 60 Water & Fire Block Data Sheet

JM CladStone 80 Water & Fire Block Data Sheet

JM CladStone 110 Water & Fire Block Data Sheet

JM CladStone Retaining Clips Data Sheet

SDS

JM CladStone Water & Fire Block SDS

JM CladStone Water & Fire Block SDS (ES)

Installation Instructions

JM CladStone Water & Fire Block Installation Instructions

Specifications and Certificates

CladStone Water and Fire Block

Industrial Insulation Group (IIG) Relationship

Mineral Wool Environmental Product Declaration (Light Density)

Mineral Wool Environmental Product Declaration (Heavy Density)

Limited Warranty

Literature

Product Selector Guide

Mineral Wool Product Comparison Chart

Mineral Wool 2.0 Sell Sheet

CladStone Sell Sheet

Wall Assemblies

Continuous Insulation for Rain-Screen Cladding Systems - Metal Panel

Continuous Insulation for Rain-Screen Cladding Systems - Fiber Cement Panel

Continuous Insulation for Cavity Wall Systems

MinWool Curtainwall

Johns Manville MinWool® Curtainwall insulation is available in a wide range of thicknesses and is available plain or with a foil facing vapor retarder. Providing superior fire resistance and acoustical properties, MinWool Curtainwall is designed for use in glass, metal and masonry curtainwall spandrel systems and can be placed between or over framing members.

Available in 2 densities, Curtainwall 40 (4.0 pcf) and Curtainwall 80 (8.0 pcf).

Advantages

Fire-Resistant: Melting point in excess of 2000˚F (1093˚C). Unfaced: Flame Spread of 0 and Smoke Developed of 0. Faced: Flame Spread of 25 or less and Smoke Development of 5 or less.

Sound Control: Excellent sound absorption to reduce sound transmission.

Durable Inorganic Glass: No growth of fungi. No sustaining of vermin.

Densities: Curtainwall 40 (4.0 pcf) and Curtainwall 80 (8.0 pcf).

| ASTM Standards | ASTM C665 | Unfaced: Type 1 Faced: Type III, Class A, Category 1 |

| Thermal Resistance | ASTM C518 | R-value R4–R-4.2 per inch |

| Flame Spread | ASTM E84 | Unfaced: 0 Faced: ≤ 25 |

| Smoke Development | ASTM E84 | Unfaced: 0 Faced: ≤ 5 |

| Water Vapor Permeance Facing | ASTM E96 | 0.02 perms, maximum |

| Water Vapor Sorption | ASTM C1104 | < 1% by weight; < 0.2% by volume at 120ºF (49ºC), 95% RH |

| Odor Emission | ASTM C1304 | Pass |

| Corrosiveness | ASTM C665 | Pass |

| Fungi Resistance | ASTM C1338 | Pass |

| Combustion Characteristics | ASTM E136 | Pass |

| ASTM C612 | Type 1–4 |

Data Sheet

MinWool Curtainwall 40 - Data Sheet

Minwool Curtainwall 80 - Data Sheet

SDS

MinWool Curtainwall SDS

MinWool Curtainwall SDS (ES)

Specifications and Certifcations

MinWool Curtainwall and Safing

Mineral Wool Environmental Product Declaration (Light Density)

Mineral Wool Environmental Product Declaration (Heavy Density)

Limited Warranty

Literature

Product Selector Guide

Mineral Wool Product Comparison Chart

Mineral Wool 2.0 Sell Sheet

MinWool Safing

Johns Manville MinWool® Safing is available plain or with a foil facing vapor retarder on one face. Nonorganic and moisture-resistant, MinWool Safing prevents smoke and flames from passing through openings in fire-rated assemblies. It is designed to provide a fire-rated seal when installed between the spandrel panel and floor slab in commercial curtainwall systems.

Advantages

Fire-Resistant: Melting point in excess of 2000˚F (1093˚C). Unfaced: Flame Spread of 0 and Smoke Developed of 0. Faced: Flame Spread of 25 or less and Smoke Developed of 5 or less.

Durable Inorganic Glass: No growth of fungi. No sustaining of vermin.

| ASTM Standards | ASTM C665 | Unfaced: Type I Faced: Type III, Class A, Category 1 |

| Flame Spread | ASTM E84 | Unfaced: 0 Faced: ≤ 25 |

| Smoke Development | ASTM E84 | Unfaced: 0 Faced: ≤ 5 |

| Water Vapor Permeance Facing | ASTM E96 | 0.02 perms, maximum |

| Water Vapor Sorption | ASTM C1104 | < 1% by weight; < 0.2% by volume at 120ºF (49ºC), 95% RH |

| Odor Emission | ASTM C1304 | Pass |

| Corrosiveness | ASTM C665 | Pass |

| Fungi Resistance | ASTM C1338 | Pass |

| Combustion Characteristics | ASTM E136 | Pass |

| ASTM C612 | Type 1–4 |

Limited Warranty

Literature

Product Selector Guide

Mineral Wool Product Comparison Chart

Mineral Wool 2.0 Sell Sheet

MinWool Sound Attenuation Fire Batt (SAFB)

Johns Manville MinWool® Sound Attenuation Fire Batt (SAFB) insulation is manufactured from inorganic fibers derived from volcanic rock. Noncombustible and moisture-resistant, the lightweight and flexible batts are designed to deliver excellent noise control in metal-stud wall cavities of interior partitions, exterior walls or above suspended ceiling systems. As excellent sound absorbers, these batts improve the wall assembly Sound Transmission Class (STC) ratings by up to 10dB.

Advantages

Sound Control: Absorbs sound and improves wall assembly STC ratings by up to 10 dB.

Fire-Resistant: Melting point in excess of 2000˚F (1093˚C). Flame Spread of 0 and Smoke Developed of 0.

Durable Inorganic Glass: No growth of fungi. No sustaining of vermin.

| ASTM Standards | ASTM C665 | Type I |

| Thermal Resistance | ASTM C518 | R-value at 75°F, 3.7 per inch of thickness |

| Flame Spread | ASTM E84 | 0 |

| Smoke Development | ASTM E84 | 0 |

| Critical Radiant Flux | ASTM E970 | > 0.12 W/ cm2 (0.11 Btu/ft2s) |

| Water Vapor Sorption | ASTM C1104 | < 1% by weight; < 0.2% by volume at 120ºF (49ºC), 95% RH |

| Odor Emission | ASTM C1304 | Pass |

| Corrosiveness | ASTM C665 | Pass |

| Fungi Resistance | ASTM C1338 | Pass |

| Combustion Characteristics | ASTM E136 | Pass |

Data Sheet

MinWool SAFB Data Sheet

MinWool SAFB Data Sheet (ES)

SDS

MinWool SAFB SDS

MinWool SAFB SDS (ES)

Limited Warranty

Literature

Product Selector Guide

Mineral Wool Product Comparison Chart

Mineral Wool 2.0 Sell Sheet

Specifications and Certificates

MinWool Sound Attenuation Fire Batt (SAFB)

Mineral Wool Environmental Product Declaration (Light Density)

Mineral Wool Environmental Product Declaration (Heavy Density)

MinWool Window Wall Insulation

Johns Manville MinWool® Window Wall Insulation is designed to be used primarily in glass and metal window wall systems. It offers superior fire resistance, and excellent thermal and acoustical insulating properties. MinWool Window Wall is made from mineral wool and bound with a thermosetting resin. Advanced manufacturing technology ensures consistent product quality, with high-fiber density and low shot content for excellent performance.

TempControl Mineral Wool

Johns Manville Mineral Wool TempControl® batts offer R-Values up to R-30. Noncombustible, fire- and moisture-resistant, they are designed to deliver thermal control and delay the spread of fire in wood-stud cavities of exterior walls, basements and heated crawlspaces.

Advantages

Thermally Efficient: Effective resistance to heat transfer with R-values up to R-30.

Fire-Resistant: Melting point in excess of 2000˚F (1093˚C). Flame Spread of 0 and Smoke Developed of 0.

Durable Inorganic Glass: No growth of fungi. No sustaining of vermin.

| ASTM Standards | ASTM C665 | Type 1 |

| Thermal Resistance | ASTM C518 | R-15, R-23, R-30 |

| Flame Spread | ASTM E84 | 0 |

| Smoke Development | ASTM E84 | 0 |

| Critial Radiant Flux | ASTM E970 | > 0.12 W/cm2 (0.11 Btu/ft2s) |

| Water Vapor Sorption | ASTM C1104 | 5% or less by weight |

| Odor Emission | ASTM C1304 | Pass |

| Corrosiveness | ASTM C665 | Pass |

| Fungi Resistance | ASTM C1338 | Pass |

| Combustion Characteristics | ASTM E136 | Pass |

Limited Warranty

Literature

Product Selector Guide

Mineral Wool Product Comparison Chart

Mineral Wool 2.0 Sell Sheet

Specifications and Certificates

Mineral Wool Environmental Product Declaration (Light Density)

Mineral Wool Environmental Product Declaration (Heavy Density)

JM Corbond 2.8

JM Corbond® 2.8 closed-cell spray polyurethane foam (SPF) is a premium, two component, 2.8 pcf insulation system designed for applications such as storage tanks, agricultural and other Class U buildings, underground, and geological operations. Its high compressive strength and outstanding dimensional stability, superior thermal and moisture performance, and exceptional sprayability and adhesion make it an ideal choice for situations where a high-performance foam is paramount.

ADVANTAGES:

Complete Coverage: Expands and adheres without shrinking or settling.

Energy-Efficient: Reduces air and moisture infiltration.

High-performance Foam: High compressive strength and outstanding dimensional stability.

Moisture Performance: Resists mold growth; meets current vapor retarder codes.

Premium two component, 2.8 pcf insulation system.

| Core Density | ASTM D1622 | 2.8 pcf |

| Closed-cell Content | ASTM D6226 | > 90% |

| Compressive Strength | ASTM D1621 | 50psi |

| Water Absorption | ASTM D2842 | 2% |

| Water Vapor Permeance | ASTM E96 | <1 perm at 1.2" |

| Smoke Development | ASTM E84 | 650 |

| Flame Spread* | ASTM E84 | <20 |

JM Corbond 2.8 has been tested according to ASTM E84, achieving a rating of 20/650

JM Corbond 2.8 HFO

JM Corbond® 2.8 HFO closed-cell spray polyurethane foam (SPF) is a premium, two component, 2.8 pcf insulation system designed for applications such as storage tanks, agricultural and other Class U buildings, underground, and geological operations. The fourth-generation technology allows JM Corbond 2.8 HFO to be produced with a low Global Warming Potential (GWP) and with an Ozone Depletion Potential (ODP) of zero. Its high compressive strength and outstanding dimensional stability, superior thermal and moisture performance, and exceptional sprayability and adhesion make it an ideal choice for situations where a high-performance foam is paramount.

| Property | Test Method | Value |

| Core Density | ASTM D1622 | 2.8 pcf |

| Closed-cell Content | ASTM D6226 | >94% |

| Dimensional Stability 158˚F at 97% RH | ASTM D2126 | <5% |

| R-Value per inch (Initial) | ASTM C518 | 6.3 (°F•ft2•h/BTU) |

| Compressive Strength | ASTM D1621 | 47 psi |

| Service Temperature Maximum | 180°F (82°C) |

JM Corbond High Yield Open-Cell

JM Corbond® High Yield Open-cell (HY OC) Spray Polyurethane Foam insulation is a two-component, low-density, E84 Class A rated, nonstructural insulation system designed for interior commercial, residential and industrial applications. JM Corbond HY OC is 100% water blown. JM Corbond HY OC offers the highest yield of any JM Corbond open-cell product. Its superior performance and exceptional sprayability make it an ideal choice for high-performing energy efficient buildings.

| SPF Acceptance Criteria | ASTM AC377 | Pass |

| Flame Spread | ASTM E84 | ≤ 25 |

| Smoke Development | ASTM E84 | ≤ 450 |

| Fungi Resistance | ASTM E283 | Pass |

| Dimensional Stability | ASTM D2126 | -8.8% Change in Volume |

| Core Density | ASTM D1622 | 0.4 pcf (normal) |

| Air Permeance | ASTM E2178-03 | < 0.02 (L/s)/m |

DATA SHEET

JM Corbond HY OC Data Sheet

JM Corbond HY OC Data Sheet (ES)

SDS

JM Corbond SDS - A

JM Corbond SDS - A (ES)

JM Corbond HY OC SDS - B

JM Corbond HY OC SDS - B (ES)

LITERATURE

Product Selector Guide

TechConnect Sell Sheet

JM Corbond High Yield Open-Cell FAQ

INSTALLATION INSTRUCTIONS

JM Corbond High Yield Open-Cell Installation Guide

JM Corbond High Yield Open-Cell Installation Guide (ES)

SPF Processing Parameters

SPF Change-over Procedure

SPF Change-over Procedure (ES)

SPF Safety Warning Sign

SPF Health and Safety Sheet

Corbond Daily Work Log

EVALUATION REPORTS

JM Corbond OC Code Compliance Research Report (CCRR-1079)

JM Corbond III

Johns Manville Corbond® III closed-cell spray polyurethane foam insulation offers and R-Value of R-7 per inch and can be applied in a single pass to a maximum of 3.5 inches, providing superior thermal performance with seamless air sealing and moisture control in a single step. Multiple pimmediate passes, with no wait time, may also be applied. With high yield and excellent adhesion, it's an ideal choice for high-performing energy efficient commercial, residential and industrial applications.

ADVANTAGES:

Complete Coverage: Expands and adheres without shrinking or settling.

Energy-Efficient: R-7.0 per inch.

Air Barrier: Prevents leaks when installed at 1” thickness or more. Tested in accordance with ASTM E2178. ABAAapproved.

Superior Moisture Performance: Resists mold growth; meets current vapor retarder codes (rating of 0.61 perms at 1-1/2” thick, in accordance with ASTM E96).

Wide Application Temperature Range: Applies between 20°F and 180°F , delivering consistent performance with seasonal versatility.

Faster Installation: Spray easily in a single pass from a minimum of .5" to a maximum of 3.5”. Multiple immediate passes, with no wait time, may also be applied. See Data Sheet for complete information.

Commercial Approvals: NFPA 285 assembly approvals.

| SPF Acceptance Criteria | ASTM AC377 | Pass |

| Flame Spread | ASTM E84 | ≤ 25 |

| Smoke Development | ASTM E84 | ≤ 450 |

| Fungi Resistance | ASTM C1388 | Pass |

| Dimensional Stability | ASTM D2126 | < 15% change in volume |

| Nominal Density | ASTM D1622 | 2 pcf |

| Closed-Cell Content | ASTM D6226 | > 90% |

| Compressive Strength (1") | ASTM D1621 | 36 psi |

| Water Absorption | ASTM D2842 | 0.9% |

| Water Vapor Transmission | ASTM E96 | 0.61 perms @ 1.5" |

| Air Permeance | ASTM E2178-03 | 0.00055 (L/s)/m at 75 Pa |

| Sound Transmission | ASTM E90-90, ASTM E413-87 | 36 (STC) |

DATA SHEET

JM Corbond III Data Sheet

SDS

JM Corbond SDS - A

JM Corbond SDS - A (ES)

JM Corbond Closed-cell SDS - B

JM Corbond Closed-cell SDS - B (ES)

LITERATURE

Product Selector Guide

JM Spray Foam Overview Brochure

JM Spray Foam Trial and Technical Support Brochure

JM Corbond III Seasonal FAQ

TechConnect Sell Sheet

INSTALLATION instructions

JM Corbond III Installation Guide

SPF Processing Parameters

SPF Change-over Procedure

SPF Change-over Procedure (ES)

SPF Safety Warning Sign

SPF Health and Safety Sheet

Corbond Daily Work Log

CERTIFICATES

JM Corbond III SPF Insulation Certificate

JM Corbond Re-Occupancy Certificate

SPRAY FOAM CERTIFICATION

SPF Certification Overview

Evaluation Reports

Corbond III IAPMO Report

Wall Assemblies

TECHNICAL BULLETINS

JM Corbond III Air Barrier Advantage

Hybrid ccSPF + Fiberglass Wall Recommendations

APPLICATION GUIDES

Penetrations - Ambient Temperature

Below Grade Wall

Change in Substrate

Crawl Space

Expansion Joint

Floor Slab to Foundation Wall

Framed Floor to Foundation Wall

High Temperature Penetrations

Interstory Connections

Parapet

Substrate Joints and Defects

Unvented Attic Insulated Roof Deck

Unvented Attic Insulated Roof Deck V2

Vaulted Ceiling

Vented Attic

Wall Corner

Window Head

SPECIFICATIONS

JM Corbond III Greenguard

JM Corbond III Greenguard Gold

JM Corbond III

CASE STUDies

All-American House Case Study

Jay Peak Resort Case Study

Vision House Case Study

JM Corbond IV

JM Corbond® IV closed-cell spray polyurethane foam (SPF) is a next generation HFO blown, two-component, Class 1 rated, medium-density, SPF insulation system. JM Corbond IV is designed to insulate commercial, residential, and industrial buildings. The HFO technology allows JM Corbond IV to be produced with a low Global Warming Potential (GWP) and with an Ozone Depletion Potential (ODP) of zero. Its high yield, superior thermal and moisture performance, and exceptional sprayability and adhesion make it an ideal choice for high-performing energy efficient buildings.

| Flame Spread | ASTM E84 | ≤ 25 |

| Smoke Development | ASTM E84 | ≤ 450 |

| Fungi Resistance | ASTM C1388 | Pass |

| Dimensional Stability | ASTM D2126 | 12% change in volume |

| Core Density | ASTM D1622 | 2.0 lb/ft3 |

| Closed-Cell Content | ASTM D6226 | > 90% |

| Compressive Strength (1") | ASTM D1621 | 36 psi |

| Water Absorption | ASTM D2842 | 0.88% |

| Water Vapor Transmission | ASTM E96 | 0.61 perm at 1.5", 1.1 perm at 1" |

| Air Permeance | ASTM E2178-03 | 0.00055 (L/s)/m at 75 Pa |

| Sound Transmission | ASTM E90-90, ASTM E413-87 | 36 (STC) |

DATA SHEET

SDS

JM Corbond SDS - A

JM Corbond SDS - A (ES)

JM Corbond IV Closed-cell SDS - B

JM Corbond IV Closed-cell SDS - B (ES)

LITERATURE

Product Selector Guide

JM Corbond IV Guide

TechConnect Sell Sheet

INSTALLATION INSTRUCTIONS

JM Corbond IV Installation Guide

SPF Processing Parameters

SPF Change-over Procedure

SPF Change-over Procedure (ES)

SPF Safety Warning Sign

SPF Health and Safety Sheet

Corbond Daily Work Log

EVALUATION REPORTS

Environmental Product Declaration Spray Polyurethane Foam Insulation (HFO) Report

JM Corbond IV IAPMO Report (ER 0146)

CERTIFICATES

Project Profile

JM Corbond Open-cell

Johns Manville Corbond® open-cell spray foam is a lower density, nonstructural insulation that offers an R-Value of R-3.8 per inch. It delivers high yield, minimizes sound transmission and virtually eliminates any air leakage. It's designed to improve energy efficiency for a wide variety of residential, commercial and industrial applications and can act as an effective air barrier.

ADVANTAGES:

Energy-Efficient: Reaches R-3.8 when installed 1” thick.

Air Barrier: Expands 120 times its volume to seal voids, gaps and crevices. Air-impermeable at 3.75”.

Sound Transmission: Performs well acoustically when used in an assembly.

Adhesion: Exceptional when properly installed.

Installation: Provides high yield with superior sprayability at an exceptional value. Meets requirements for application without an ignition barrier in unoccupied and unvented attics and crawl spaces.

| SPF Acceptance Criteria | ASTM AC377 | Pass |

| Flame Spread | ASTM E84 | ≤ 25 |

| Smoke Development | ASTM E84 | ≤ 450 |

| Fungi Resistance | ASTM E283 | Pass |

| Dimensional Stability | ASTM D2126 | < 15% change in volume |

| Nominal Density | ASTM D1622 | 0.5 pcf (normal) |

| Open-Cell Content | ASTM D6226 | > 92% |

| Water Vapor Transmission | ASTM E96 | 26.5 perms @ 2" |

| Air Permeance | ASTM E2178-03 | < 0.02 (L/s)/m |

| Sound Transmission | ASTM E90-90, ASTM E413-87 | 38 (STC) |

DATA SHEET

JM Corbond oc SPF Data Sheet (US)

SDS

JM Corbond SDS - A

JM Corbond SDS - A (ES)

JM Corbond ocSPF SDS - B

JM Corbond ocSPF SDS - B (ES)

LITERATURE

Product Selector Guide

JM Spray Foam Overview Brochure

JM Spray Foam Trial and Technical Support Brochure

JM Corbond oc ocx Sell Sheet

TechConnect Sell Sheet

SPRAY FOAM CERTIFICATION

SPF Certification Overview

INSTALLATION instructions

JM Corbond oc SPF Processing Parameters

JM Corbond oc SPF Processing Parameters (ES)

JM Corbond® SPF Change Over Procedure

JM Corbond SPF Change-over Procedure (ES)

JM Corbond oc SPF Installation Guide

SPF Safety Warning Sign

SPF Health and Safety Sheet

JM Corbond Re-Occupancy Certificate

JM oc SPF for Unvented Attics Insulation Certificate

Unvented Attic Hatch Guide

Corbond Daily Work Log

Specifications

evaluation reports

Code Compliance Research Report CCRR-1079

CASE STUDY

inSPIRE Rock Climbing Center Case Study

JM Corbond Open-cell Appendix X

Johns Manville Corbond® Open-cell Appendix X spray foam provides an R-Value of R-3.7 per inch, and meets AC 377 NFPA 286 Appendix X requirements for application without an ignition barrier in attics and crawl spaces. This low-density, nonstructural insulation allows for high yield while prodiving excellent heat, air and sound control. Recommended for use in residential, commercial and industrial applications.

ADVANTAGES:

Energy-Efficient: Reaches R-3.7 when installed 1” thick.

Air Barrier: Air-impermeable at 3.5”.

Sound Transmission: Performs well acoustically when used in an assembly.

Installation: Provides high yield with superior sprayability at an exceptional value. Meets requirements for application without an ignition barrier in unoccupied and unvented attics and crawl spaces.

| SPF Acceptance Criteria | ASTM AC377 | Pass |

| Flame Spread | ASTM E84 | ≤ 25 |

| Smoke Development | ASTM E84 | ≤ 450 |

| Air Leakage Rate | ASTM E283 | < 0.02 (L/S/m2) @75pa |

| Fungi Resistance | ASTM E283 | Pass |

| Dimensional Stability | ASTM D2126 | < 15% change in volume |

| Nominal Density | ASTM D1622 | 0.5 pcf (normal) |

| Open-Cell Content | ASTM D6226 | > 95% |

| Water Vapor Transmission | ASTM E96 | 9 perms @ 3.5" |

| Air Permeance | ASTM E2178-03 | < 0.02 (L/s)/m |

| Sound Transmission | ASTM E90-90, ASTM E413-87 | 38 (STC) |

DATA SHEET

JM Corbond oc SPF Data Sheet (US)

SDS

JM Corbond SDS - A

JM Corbond SDS - A (ES)

JM Corbond ocSPF SDS - B

JM Corbond ocSPF SDS - B (ES)

LITERATURE

Product Selector Guide

JM Spray Foam Overview Brochure

JM Spray Foam Trial and Technical Support Brochure

JM Corbond oc ocx Sell Sheet

TechConnect Sell Sheet

INSTALLATION instructions

JM Corbond ocx SPF Processing Parameters

JM Corbond ocx SPF Processing Parameters (ES)

JM Corbond® SPF Change Over Procedure

JM Corbond SPF Change-over Procedure (ES)

SPF Safety Warning Sign

SPF Health and Safety Sheet

JM Corbond Re-Occupancy Certificate

Corbond Daily Work Log

Specifications

evaluation reports

JM Corbond ocx SPF IAPMO ES Report

SPRAY FOAM CERTIFICATION

SPF Certification Overview

No-Burn Plus ThB

Johns Manville has partnered with No-Burn, Inc. to offer No-Burn Plus ThB. This tintable white, thin film intumescent coating can be applied over JM open- and closed-cell polyurethane foams. When exposed to high temperatures and flame it intumesces, which creates a char-barrier to reduce heat transfer and surface burning in the event of a fire. This nontoxic, water-based coating complies with IRC and IBC and can serve in lieu of otherwise code-prescribed thermal barriers.

| Color | Opaque/White/Tinted |

| Finish | Flat |

| VOC Content | 18 g/L EPA Method 24 |

| Dry Time | 60-90 minutes |

| Pails | 5 gallons (19 L), 57.5 lbs. |

| Drums | 55 gallons (208 L), 632.5 lbs. |

| Shelf Life | 18 months |

| Cure Time | 24 hours |

| Boiling Point | 212°F |

| Freezing Point | 32°F |

| % Volatile by Volume | 33% |

| Specific Gravity | 1.25 |

Data Sheet

JM No-Burn Plus ThB Data Sheet

SDS

JM No-Burn Plus ThB White SDS

JM No-Burn Plus ThB SDS (ES)

JM No-Burn Black Tint SDS

JM No-Burn Black Tint SDS (ES)

No-Burn Plus ThB Custom Color Tint

No-Burn Plus ThB Custom Color Tint (ES)

No-Burn Plus ThB Gray

No-Burn Plus ThB Gray (ES)

No-Burn Plus ThB Dark Charcoal

No-Burn Plus ThB Dark Charcoal (ES)

Literature

Evaluation Report

Certificates

Bulletins

Spray Foam Parts and Equipment

We have on-staff experts designated to helping you select the right parts and equipment for your spray foam rig. Our spray foam team has access to an extensive catalog of spray foam parts and equipment with overnight shipping capabilities for emergencies. You can connect with our technical service representative via phone, email, video calls or even text message to ensure you are ordering the correct part. Click here for more details.

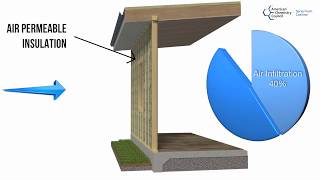

AP Foil-Faced Foam Continuous Insulation

Johns Manville AP™ Foil-Faced Polyiso Foam Sheathing boards are available in R-Values up to R-28 and offer a reflective foil facer on one side and a non-reflective facer on the other. AP Foil provides exceptional heat, moisture and air control and, when installed correctly, eliminates all major thermal bridges that cause heat loss. The rigid continuous insulation board allows for maximum wall and worksite efficieny.

Advantages

Thermally Efficient: Effective resistance to heat transfer, with R-values up to R-28.

Water-Resistive Barrier: Meets the ICC-ES AC71 acceptance criteria.

Vapor Barrier: Class I vapor retarder at one inch.

Air Barrier: Meets the Air Barrier Association of America boardstock criteria, when properly installed.

Lightweight: Easy to handle and may be cut with a utility knife or saw.

| ASTM Standards | ASTM C1289 | Type I, Class 1 |

| Flame Spread | ASTM E84 | 4": ≤ 25 |

| Smoke Development | ASTM E84 | ≤ 450 |

| Water Vapor Transmission | ASTM E96 | 0.05 perms (3 ng/Pa-s-m2) |

| Compressive Strength | ASTM D1621 | ≥ 16 psi (110 kPa) |

| Water Absorption | ASTM C209 | 0.1% volume |

| Service Temperature | -100 to 250°F | |

| R-Value Per Inch | 6.0 |

Data Sheet

AP Foil-Faced Foam Sheathing Data Sheet

SDS

AP Foil-Faced Foam Sheathing SDS

AP Foil-Faced Foam Sheathing SDS (ES)

Installation Instructions

JM Continuous Insulation Wall System Installation Guide

Technical Bulletin 302: Wall Bracing with Polyiso CI

JM AP Foil Faced Sheathing Below-Grade Interior Walls Installation Instructions

JM AP Foil Faced Sheathing Below-Grade Exterior Walls Installation Instructions

JM AP Foil Faced Sheathing Crawl Spaces Installation Instructions

AP Foil Faced Insulation Sheathing Board Attics and Cathedral/Vaulted Ceiling Installation Instructions

AP Foil Residential Installation Instructions - Above Grade Exterior Walls,Technical Guide

Technical Bulletin

JM AP Foil - NFPA 285 Wall Assemblies

STC Rating Documents

Acoustical Assemblies STC Rating Reference Guide

Wall Assemblies

Continuous Insulation for Stucco Wall Systems - Option One

Continuous Insulation for Stucco Wall Systems - Option Two

Continuous Insulation for Stucco Wall Systems - Option Three

Continuous Insulation Wall System

Continuous Insulation

Continuous Insulation Website

Technical Bulletin 301: Polyiso CI Performance in Residential Wall Applications

Technical Bulletin 303: Moisture Control with Polyiso CI

Technical Bulletin 304: Energy Efficiency with Polyiso CI

Evaluation Reports

Literature

Product Selector Guide

JM All-Purpose Wall System Sell Sheet

PIMA - Polyiso Wall Insulation Boards EPD

PIMA Performance Bulletin - Polyiso vs. XPS

JM All-Purpose Wall System Components Sheet

NFPA 285 ACM Assemblies Announcement

Certifications and Specifications

JM Continuous Insulation Wall System Specification, Section 072100 - Foil Faced Rigid Insulation

Polyiso Sheathing EPD

Case Study

JM Castle Pines Case Study

Vision House Case Study

Warranties

CI Max Foam Continuous Insulation

Johns Manville CI Max® Polyiso Foam Continuous Insulation is available in R-Values up to R-26 and provides a layer of insulation to reduce thermal bridging and improve energy efficiency. CI Max Continuous Insulation is designed for exposed interior applications and is approved for use without a thermal barrier. It is suitable for wall or ceiling applications in residential, commercial, agricultural and industrial buildings.

Advantages

Thermally Efficient: Effective resistance to heat transfer, with R-values up to R-26.

Vapor Barrier: Maintains a minimum thickness of one inch and qualifies as a Class I vapor retarder.

Lightweight: Easy to handle and may be cut with a utility knife or saw.

| ASTM Standards | ASTM C1289 | Type I, Class 1 |

| Flame Spread | ASTM E84 | 4": ≤ 25 |

| Smoke Development | ASTM E84 | ≤ 450 |

| Water Vapor Transmission | ASTM E96 | 0.02 perms (1.4 ng/Pa-s-m2) |

| Compressive Strength | ASTM D1621 | ≥ 16 psi (110 kPa) |

| Water Absorption | ASTM C209 | < 0.6% volume |

| Service Temperature | -100 to 250°F | |

| R-Value Per Inch | 6.0 |

Data Sheet

CI Max Foam Sheathing Data Sheet

SDS

CI Max Foam Sheathing SDS

CI Max Foam Sheathing SDS (ES)

Installation Instructions

CI Max for Exposed Interior Use

Warranties

Literature

Product Selector Guide

PIMA - Polyiso Wall Insulation Boards EPD

PIMA Performance Bulletin - Polyiso vs. XPS

JM All-Purpose Wall System Components Sheet

Evaluation Reports

Certifications and Specifications

JM CI Max Guide Specifications in CSI Format

JM Continuous Insulation Wall System Specification, Section 072100 - Foil Faced Rigid Insulation

Polyiso Sheathing EPD

= view sheets

= view sheets