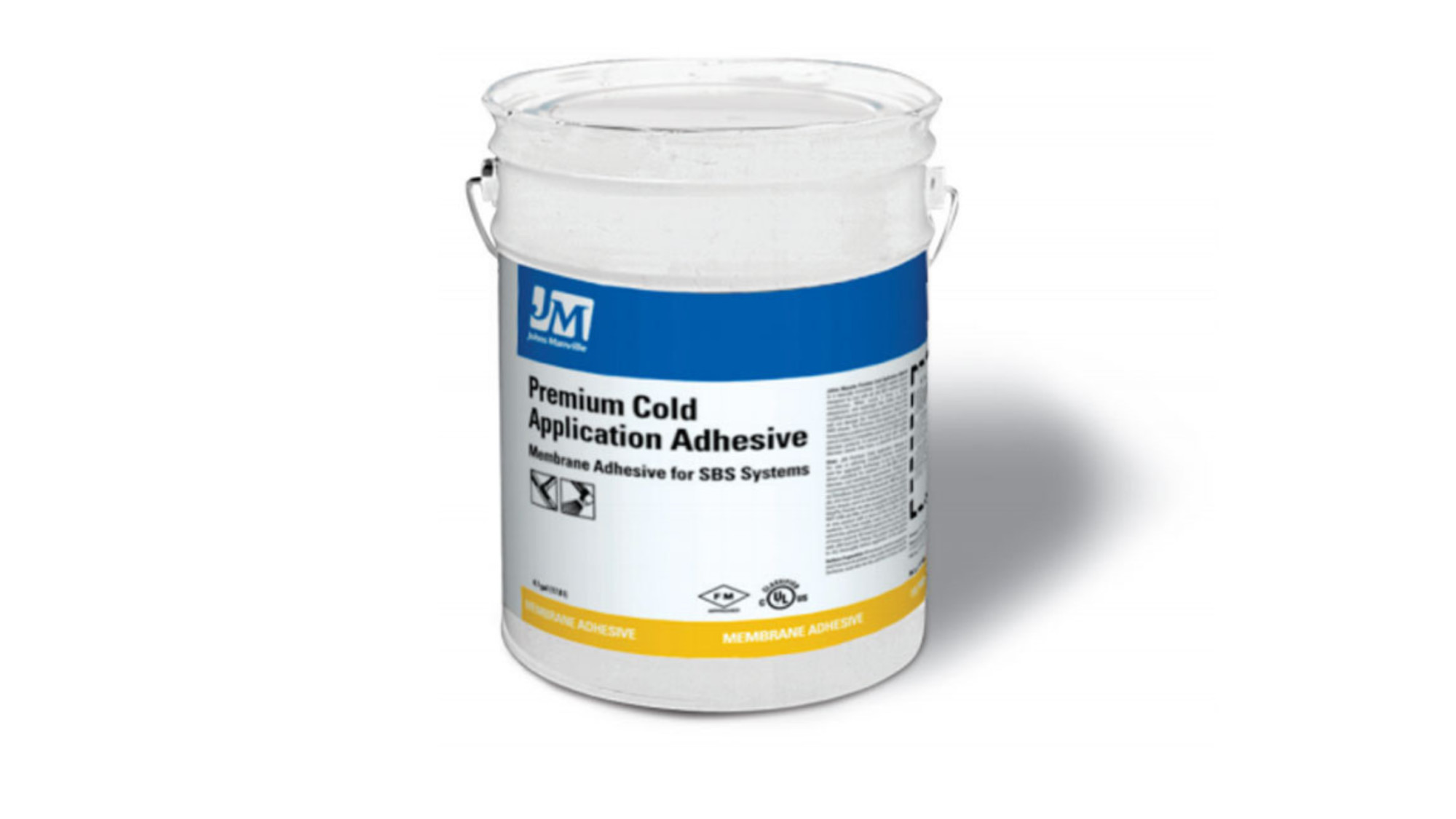

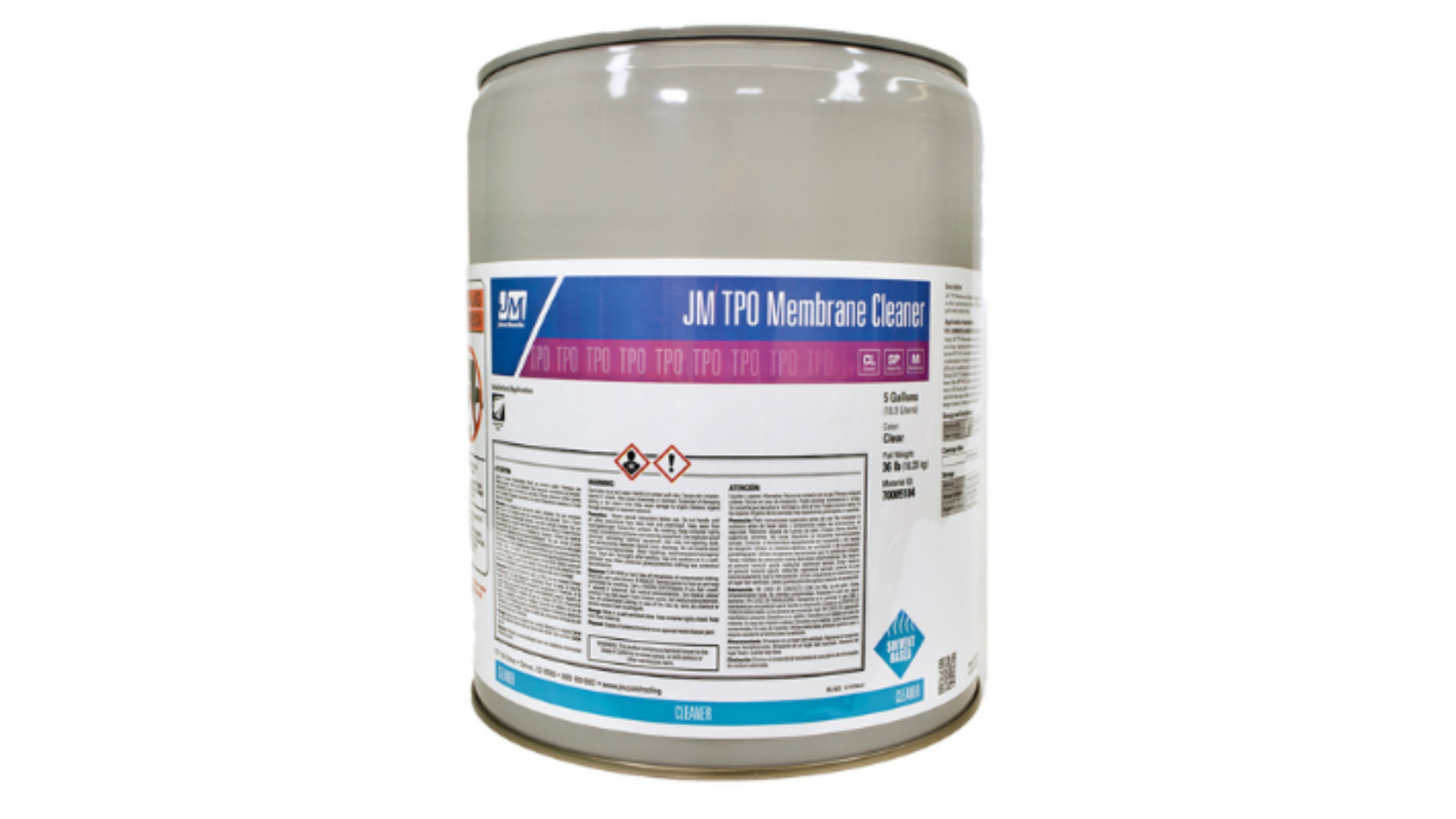

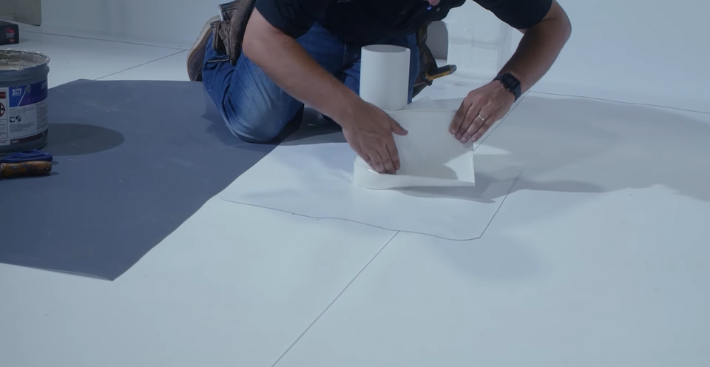

Adhesives, Cements, and Primers

Adhesives, Cements, and Primers

- Family Description

- We provide an extensive line of adhesives and cements for all roof types. Our selection includes sealants, cleaners and primers for every step of the installation process. We have products designed to meet specific regional regulations and environmental requirements, work with different substrates and, in some cases, be used with multiple membranes.