Resources

Products

Foam Board / Continuous Insulation

Johns Manville Polyiso foam sheathing insulation boards provide a continuous layer of insulation to reduce thermal bridging and improve energy efficiency. Polyiso consists of a uniform closed-cell polyisocyanurate foam core and provides one of the highest R-values per inch of any rigid insulation.

Foam Board, Continuous Insulation

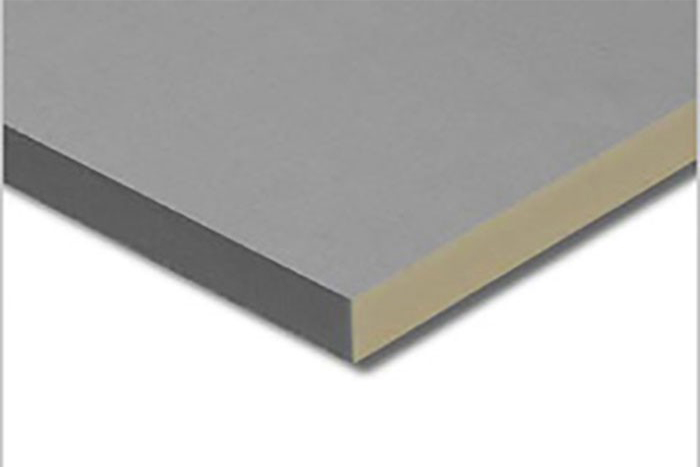

AP Breathing Sheathing

Johns Manville AP™ Breathing Sheathing Polyiso Continuous Insulation board is a breathable continuous polyiso insulation, which is designed to be semi vapor permeable. AP Breathing Sheathing consists of a uniform closed-cell polyisocyanurate foam core bonded to a coated glass facer on both sides of the board. Polyiso provides one of the highest R-values per inch of any rigid insulation.

| PROPERTY | UNITS | NOMINAL VALUE | TEST METHOD |

| Compressive Strength | kPa (psi) | >140 (> 20.3) | ASTM D1621 |

| Tensile Strength | kPa (psi) | >24 (> 3.48) | ASTM D1623 |

| Flexural Strength | kPa (psi) | 655 (95) | ASTM C203 |

| Water Absorption | % vol | 1% (max) | ASTM D2842 |

| Dimensional Stability | % | ± 2 | ASTM C2126 |

| Water Vapor Transmission Rate | ng/Pa•s•m2 (perms) | >60 (>1) | ASTM E96 (Method B) |

| Flame / Smoke Spread | - | <55/500 | CAN/ULC-S102 |

| Service Temperature | °C (°F) | -73°C to 121°C (-100°F to 250°F) | - |

| Width Tolerance | mm (in) | ≤+4 (0.16") | ASTM C303 |

| Length Tolerance | mm (in) | ≤+6 (0.24") | ASTM C303 |

| THICKNESS (in) | R-VALUE* | THICKNESS (mm) | RSI-VALUE | BOARD SIZE (ft) |

| 1 | 5.7 | 25 | 1.00 | 4x8 |

| 1.5 | 8.5 | 38 | 1.5 | 4x8 |

| 2 | 11.4 | 51 | 2.01 | 4x8 |

AP Foil-Faced Foam Continuous Insulation - Canada

Johns Manville AP Foil-Faced Polyiso Foam Sheathing boards are available up to RSI 5.09 (R-28) and offer a reflective foil facer on one side and a non-reflective facer on the other. AP Foil provides exceptional heat, moisture and air control and, when installed correctly, eliminates all major thermal bridges that cause heat loss. The rigid continuous insulation board allows for maximum wall and worksite efficiency.

Advantages

Thermally Efficient: Effective resistance to heat transfer, with R-values up to R-28 (RSI-5.09).

Water-Resistant Barrier: Meets the NBC acceptance criteria CCMC-13104-L.

Vapour Barrier: Class I vapour retarder at 25mm (1”).

Lightweight: Easy to handle and can be cut with a utility knife or saw.

| CCMC Evaluation Listing | CCMC Evaluation Listing | |

| Standard | CAN/ULC S704 | Type 1, Class 1 |

| Flame Spread Rating | CAN/ULC S102 | < 500 at 25mm |

| Water Vapour Transmission | ASTM E96 | 0.05 perms (3 ng/Pa-s-m2) |

| Compressive Strength | ASTM D1621 | ≥ 16 psi (110 kPa) |

| Dimensional Stability | ASTM D2126 | 2% max, 7 days (length & width) |

| Water Absorption | ASTM C209 | 0.1% volume |

| Thermal Performance at 25mm | RSI/R-Value per ASTM C518 |

Data Sheet

AP Foil-Faced Foam Sheathing Data Sheet

AP Foil-Faced Foam Sheathing Data Sheet (FR)

SDS

AP Foil-Faced Foam Sheathing SDS

AP Foil-Faced Foam Sheathing SDS (FR)

Literature

Product Selector Guide

Product Selector Guide (FR)

JM All-Purpose Wall System Sell Sheet

PIMA Performance Bulletin - Polyiso vs. XPS

Evaluation Reports/Certificates

Installation instructions

JM Continuous Insulation Wall System Installation Guide

JM AP Foil Faced Sheathing Below-Grade Interior Walls Installation Instructions

JM AP Foil Faced Sheathing Below-Grade Exterior Walls Installation Instructions

JM AP Foil Faced Sheathing Crawl Spaces Installation Instructions

AP Foil Faced Insulation Sheathing Board Attics and Cathedral/Vaulted Ceiling Installation Instructions

AP Foil Residential Installation Instructions - Above Grade Exterior Walls, Technical Guide

R-Panel Roof Insulation - Canada

Johns Manville R-Panel rigid roof insulation board provides high thermal efficiency. R-Panel is manufactured with a closed-cell polyisocyanurate foam core bonded to fibreglass-reinforced facers and designed for use over metal, nailable and non-nailable roof decks with a variety of membrane systems. R-Panel meets the International Building Code requirements for a foamed plastic roof insulation.

Advantages

Thermally Efficient: Effective resistance to heat transfer.

Universal Facer: Compatible with BUR, modified bitumen and single-ply membrane systems.

Lightweight: Easy to handle and can be cut with a utility knife or saw.

| CCMC Evaluation Listing | 13058-L | |

| Standard | CAN/ULC S704 | Type II, Class 3 |

| Flame Spread Rating | CAN/ULC S102 | < 500 at 25mm |

| Water Vapour Transmission | ASTM E96 | < 1.5 perms (57.5 ng/Pa-s-m2) |

| Compressive Strength | ASTM D1621 | 1 perm, 57.2 ng/ (Pa•s•m2) (nom), 1.5 perm, 85.8 ng/ (Pa•s•m2) (max) |

| Dimensional Stability | ASTM D2126 | 2% max, 7 days (length & width) |

| Water Absorption | ASTM C209 | < 1% volume |

| Service Temperature | -73° to 121°C (-100° to 250°F) | |

| Thermal Performance at 25mm | LTTR per CAN ULC S770 |